Electrostatic spinning collection device and method, and electrostatic spinning equipment

An electrospinning and collecting device technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of disordered fibers, unsuitable for highly ordered organization, etc., and achieve the effect of high degree of fiber orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

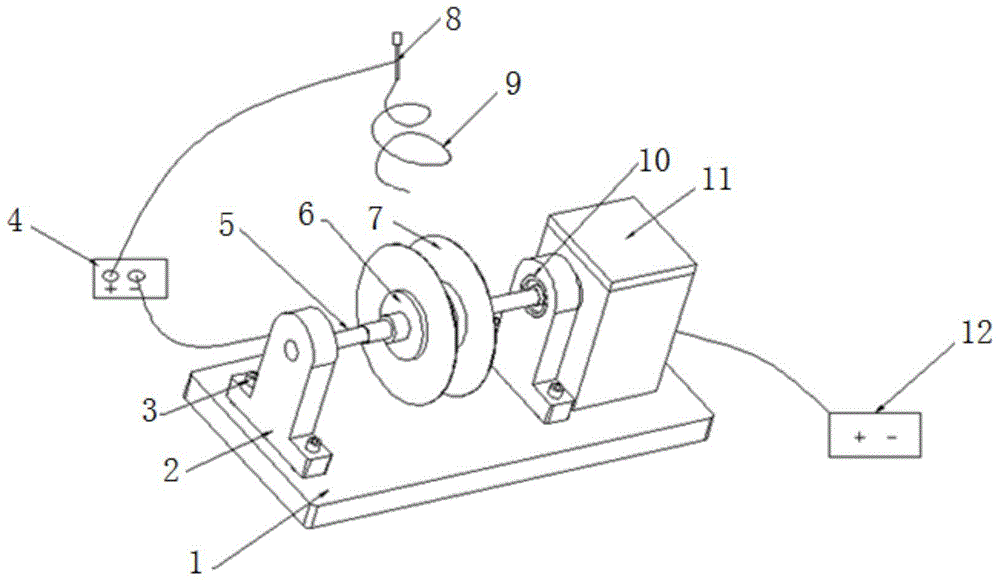

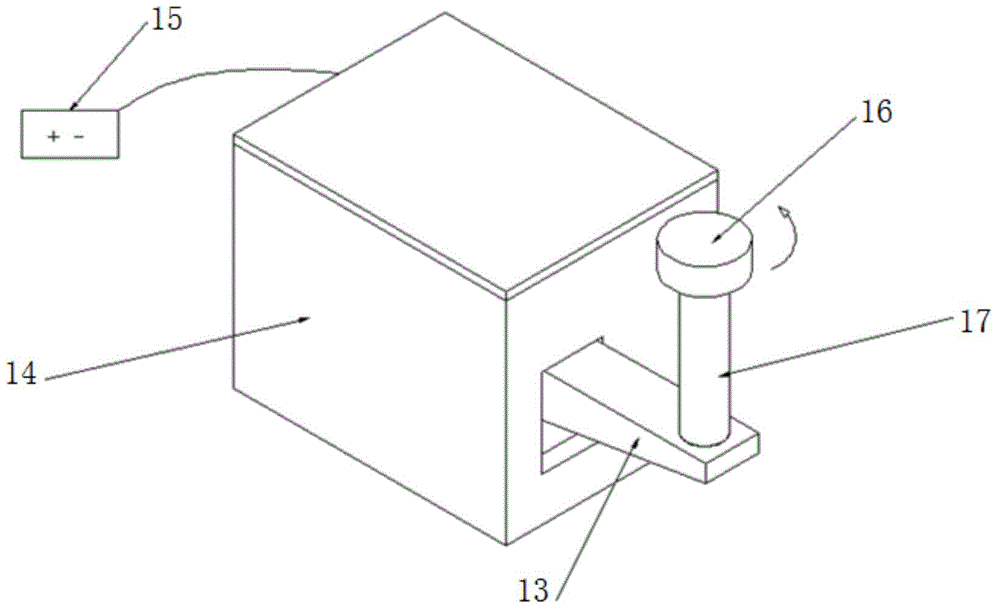

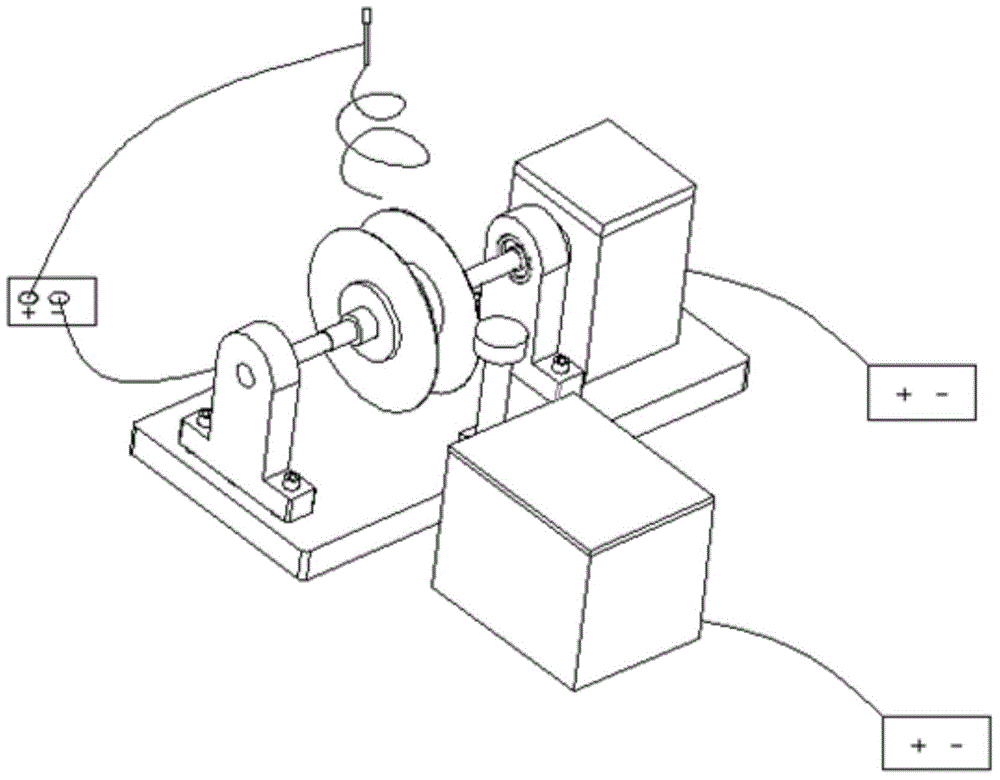

[0045] The uniaxial PVA fiber scaffold was electrospun using the above-mentioned device and method. The PVA concentration is 10%, the solution flow rate is set to 0.3ml / h, the voltage is 15KV, the distance between the needle tip of the syringe and the parallel thin disk is 175mm, the rotation speed of the thin disk is 500r / min, and the distance between the parallel thin disks is 38mm , the ambient temperature of electrospinning was 37. The rotatable planar fiber collector is fixed at a certain position, so that the circular collecting disc in the rotatable planar fiber receiving device is located between the two thin plates, and the circular collecting disc is kept stationary to collect oriented fibers in one direction. The electrospinning time was 3h. The obtained uniaxially oriented fibers are as Figure 4 shown.

example 2

[0047] Biaxial PVA fiber scaffolds were electrospun using the above devices and methods. Wherein the PVA concentration is 10%, the set solution flow rate is 0.5ml / h, the voltage is 12KV, the distance between the needle point of the syringe and the parallel thin dish is 175mm, the thin dish rotating speed is 800r / min, and the distance between the parallel thin dish is 43mm, The circular collecting disk in the rotatable planar fiber collector moves at a speed of 5 mm / s, a rotation period of 10 min, a rotation angle of 90 degrees, a rotation speed of 10 mm / s, and an electrospinning environment temperature of 37. The electrospinning time was 2h. The obtained biaxially oriented fibers are as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com