Oil inlet valve and high-pressure common rail fuel pump using same

A high-pressure common rail and oil inlet valve technology, applied in fuel injection pumps, engine components, machines/engines, etc., can solve problems such as reduced fuel supply efficiency, stuck oil inlet valves, uneven force on the sealing surface, etc., to achieve reduction The effect of small high-pressure fuel backflow, preventing the oil inlet valve from being stuck, and improving product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

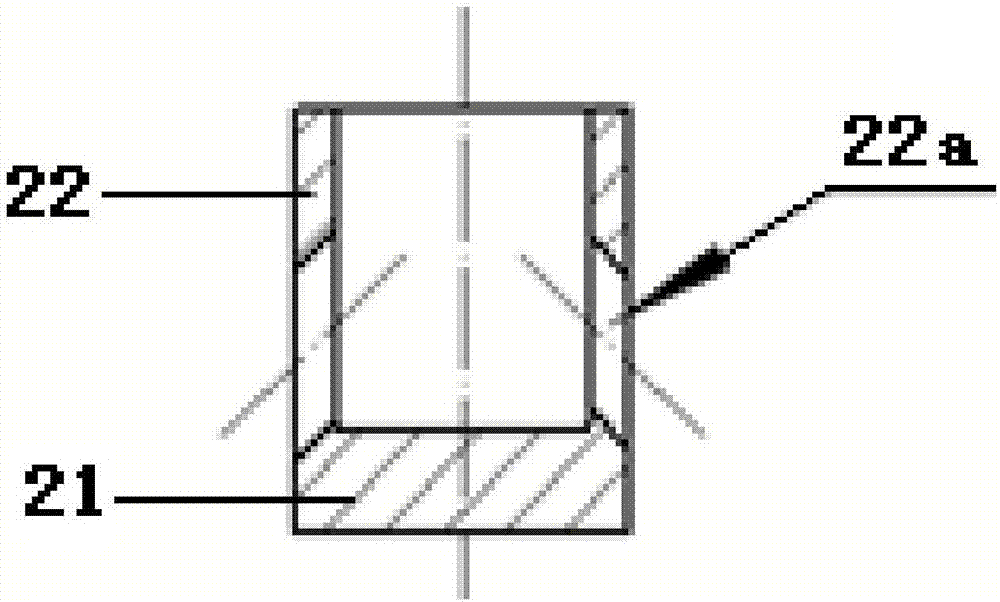

[0026] The invention provides an oil inlet valve and a high-pressure common rail pump using the oil inlet valve. see image 3 As shown, the oil inlet valve includes a circular valve plate 21 and a hollow guide cylinder 22 connected to the circular valve plate 21, and the guide cylinder 22 is connected with the circular valve plate 21 to form a cylinder with an inner cavity. shaped structure. Wherein, a plurality of oil holes 22a are opened on the wall of the guide cylinder 22 . Preferably, the circular valve plate 21 and the guide cylinder 22 are integrally formed and precisely processed.

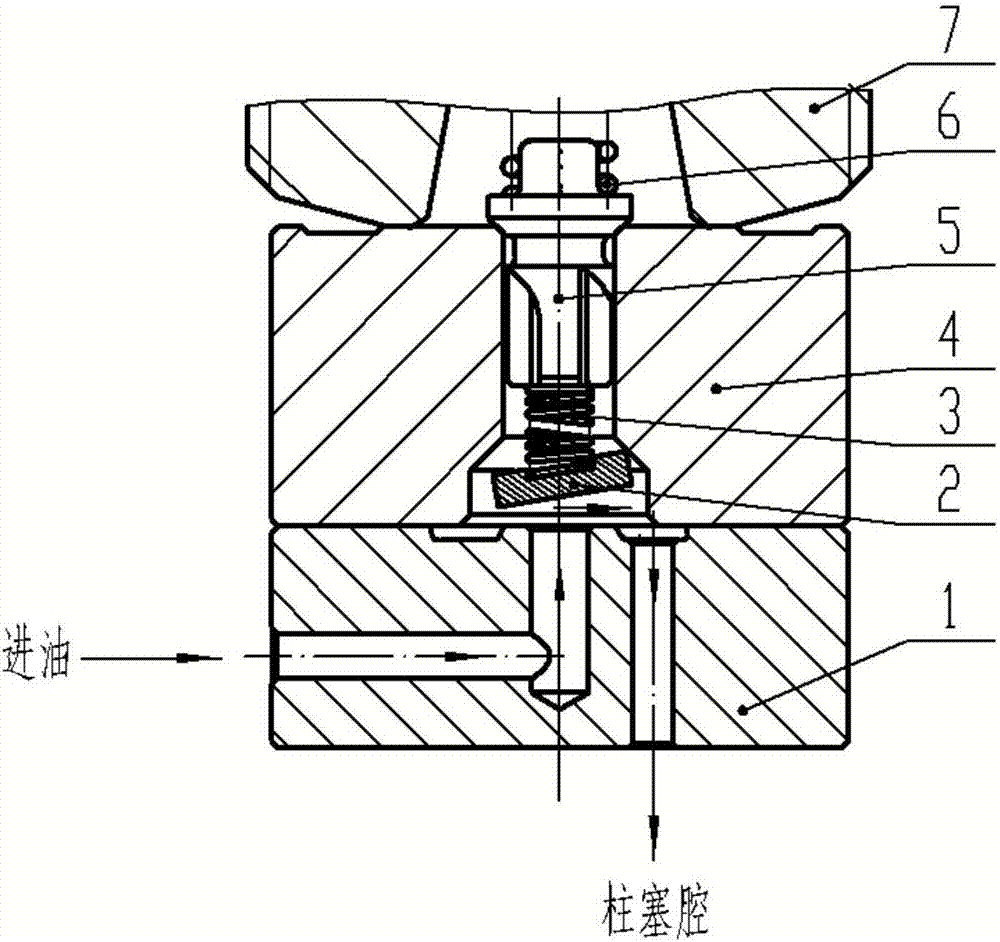

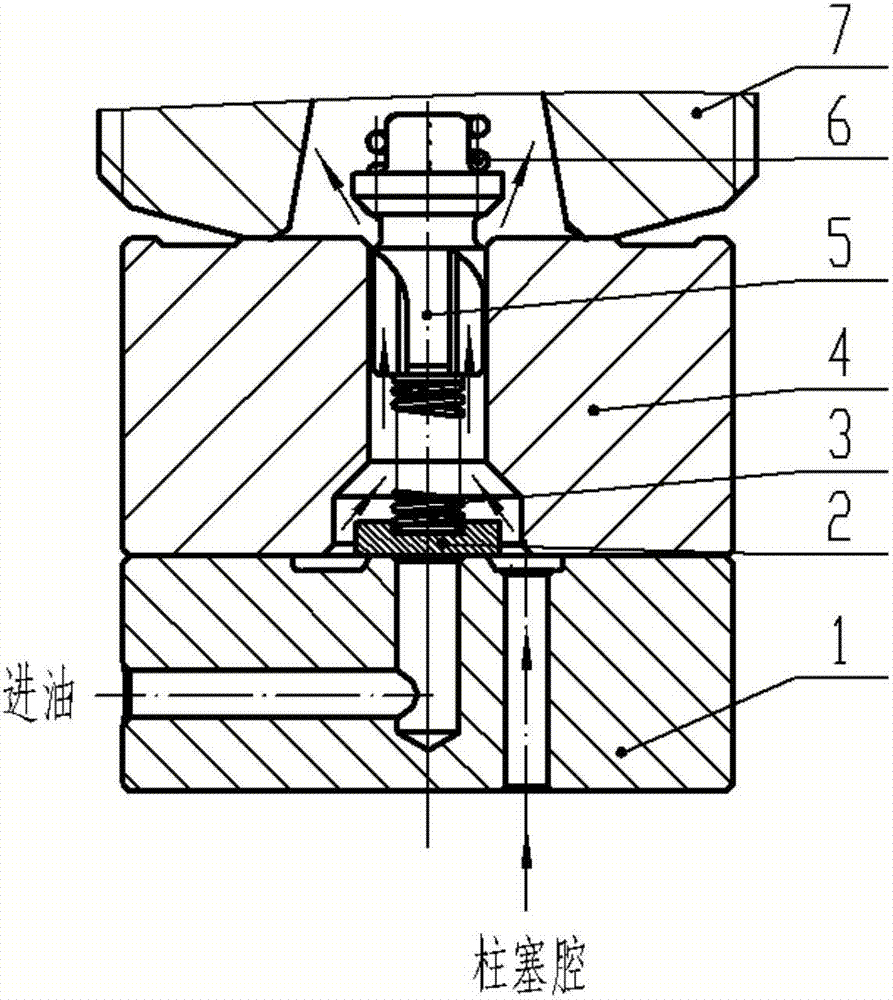

[0027] Please refer to Figure 4 , 5 As shown, when in use, the oil inlet valve 2 is installed on the oil inlet valve seat 1 in the high-pressure common rail pump. The end faces are sealed. The upper part of the oil inlet valve seat 1 is the matching oil outlet valve seat 4, and the middle part of the oil outlet valve seat 4 is provided with a vertical cavity, and the upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com