Method for carrying out sputtering deposition to form piezoelectric film on flexible glass

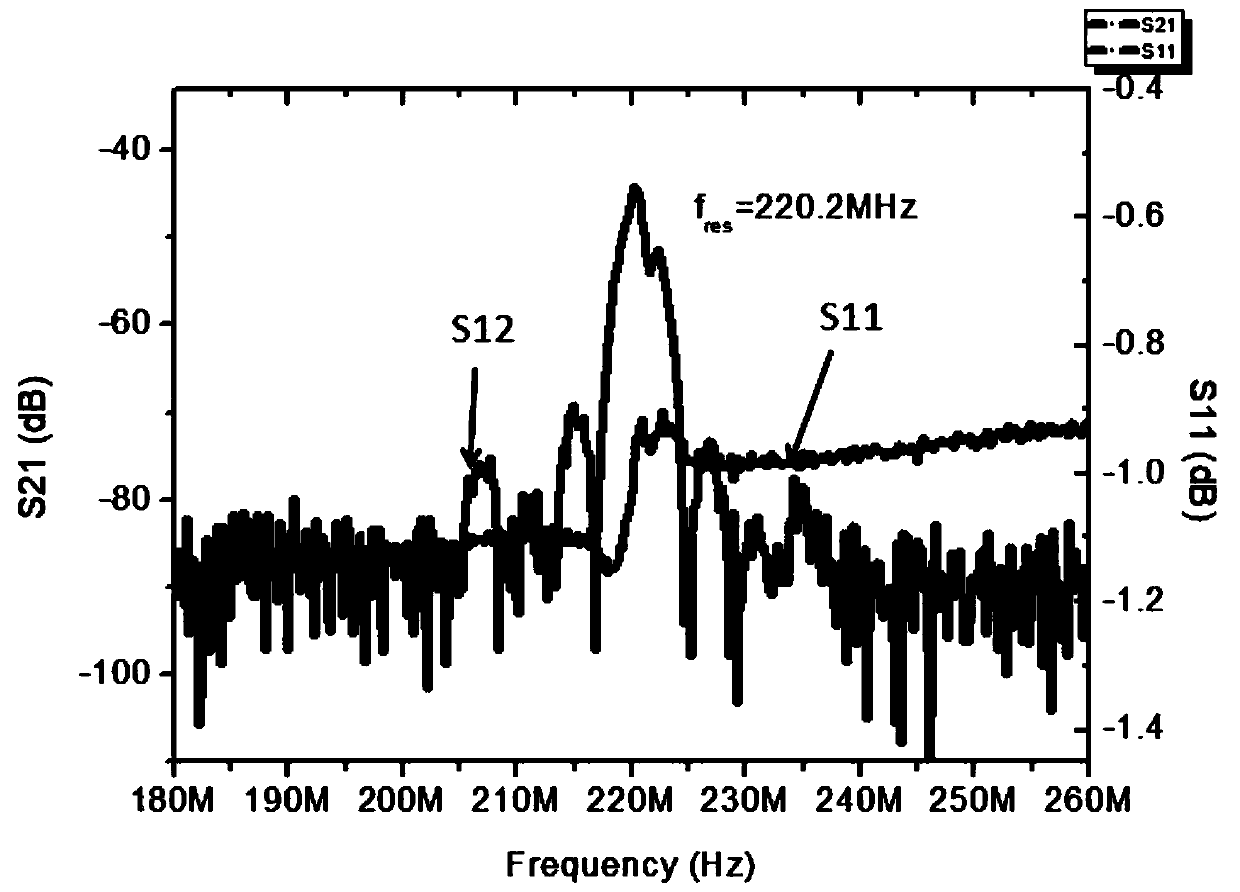

A technology of flexible glass and piezoelectric film, which is applied in the field of electronic materials, can solve the problems of insufficient signal amplitude, limitation of high-performance flexible sensing and application, and difficulty in driving microfluidics with flexible SAW, so as to achieve large signal amplitude of the device, Improve the effect of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for sputtering and depositing a piezoelectric thin film on flexible glass, comprising the following steps:

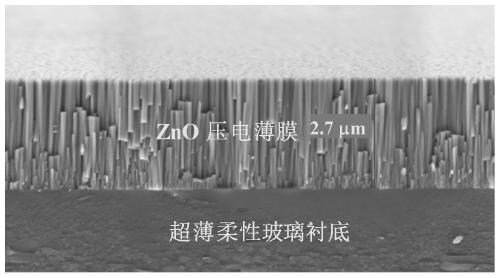

[0040] 1) Ultra-thin flexible glass with an area of 2 inches was ultrasonically cleaned with acetone, then ultrasonically cleaned with deionized water twice, then ultrasonically cleaned with absolute ethanol, and then dried with nitrogen, and the cleaned flexible glass was attached to the The surface of the substrate cooling device in the vacuum chamber of the magnetron sputtering coating machine; paste the cleaned flexible ultra-thin glass on the flat substrate in the vacuum chamber of the magnetron sputtering equipment;

[0041] 2) Then evacuate until the vacuum degree of the flat substrate is 5×10 -4 Pa;

[0042] 3) Depositing ZnO on the surface of the flexible glass by atomic layer deposition, specifically feeding argon gas, adjusting the flow rate so that the argon gas pressure is 5×10 -1Pa; close the baffle plate of the substrate, turn on the D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com