Hot air circulation structure and oven

A hot air circulation and oven technology, which is used in roasters/barbecue grids, kitchen utensils, household utensils, etc. Efficiency, the effect of improving the uniformity of the air outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

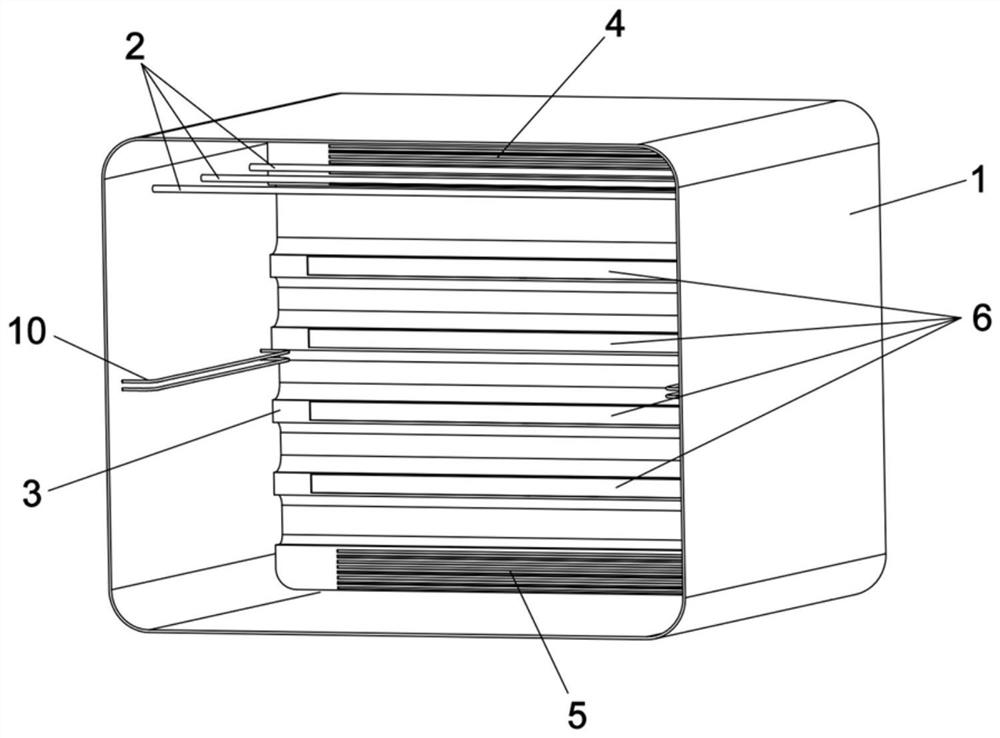

[0038] This embodiment provides a hot air circulation structure, which can be used in baking equipment such as ovens. The hot air circulation structure can effectively improve the uniformity of the hot air flow, thereby effectively improving the uniformity of the temperature field inside the oven, shortening the baking time, and improving Improve the utilization rate of heat energy, improve the color uniformity and baking efficiency of baked food.

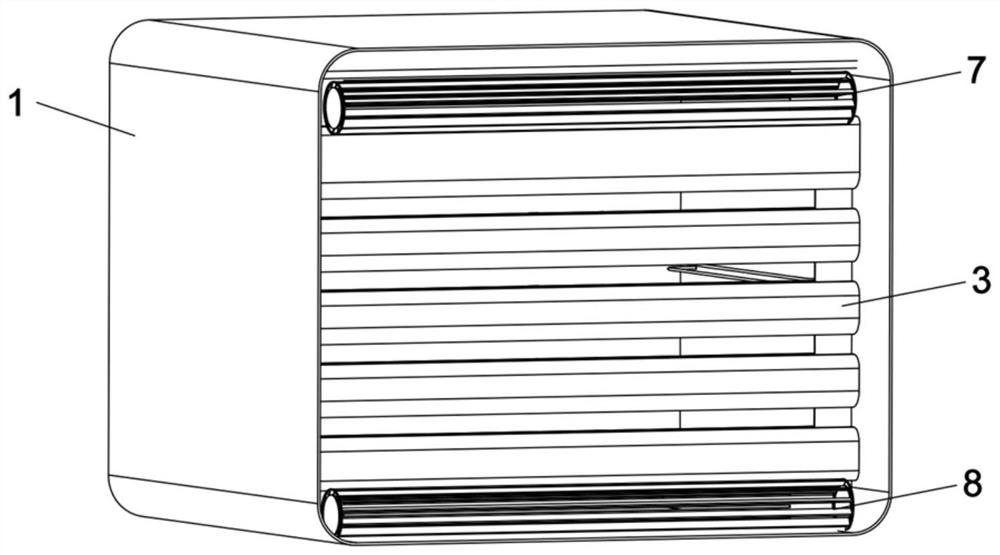

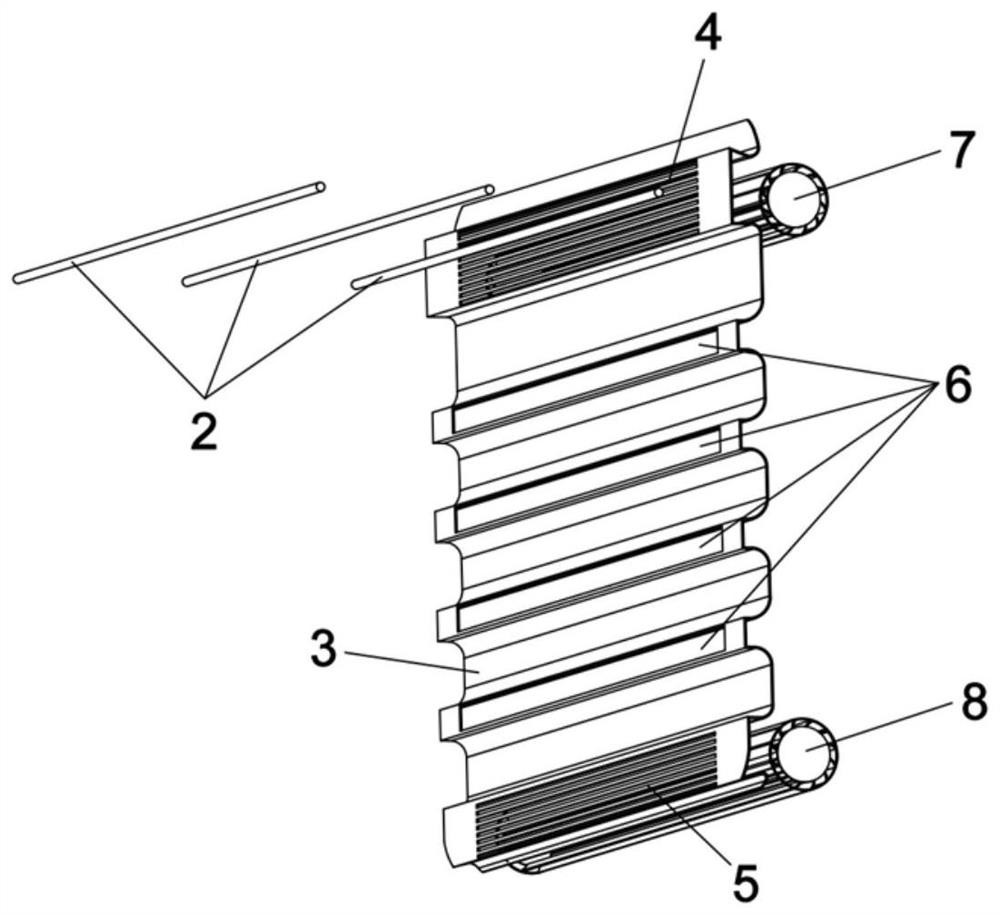

[0039] Such as Figure 1 to Figure 4 As shown, the hot air circulation structure mainly includes an inner tank 1, a cover plate 3, a heating pipe and a hot air blower, wherein the heating pipe includes an upper heating pipe 2 and a lower heating pipe (not shown in the figure), and the hot air blower includes an upper hot air blower 7 and the lower hot air blower 8. The upper heating pipe 2 and the lower heating pipe are respectively arranged on the top and the bottom of the inner container 1 for heating the air in the inner contai...

Embodiment 2

[0051] This embodiment provides a hot air circulation structure, which differs from the hot air circulation structure in Embodiment 1 in that:

[0052] Such as Figure 5 to Figure 7 As shown, the hot air circulation structure further includes a switch piece 9 , which is rotatably arranged at the air outlet 6 , and the switch piece 9 is used to open or close the air outlet 6 .

[0053] The switch piece 9 includes a body 91 and a toggle portion 92 connected to the bottom of the body 91. The length of the body 91 is not less than the length of the air outlet 6, and the width (dimension along the vertical direction) of the body 91 is slightly smaller than the width of the air outlet 6. , the two sides of toggle part 92 are provided with rotating shaft 93, switch piece 9 is connected with the bottom of air outlet 6 through this rotating shaft 93, and rotating shaft 93 is provided with torsion spring (not shown in the figure). The torsion spring makes the air outlet 6 appear to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com