No-secondary light spot LED reflector

A reflector and sub-spot technology, which is applied in the field of reflectors, can solve the problems of uneven brightness in the illumination area, waste of light source illumination, and easy to cause myopia, etc., and achieve the effects of avoiding uneven illumination, good guidance, and good brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

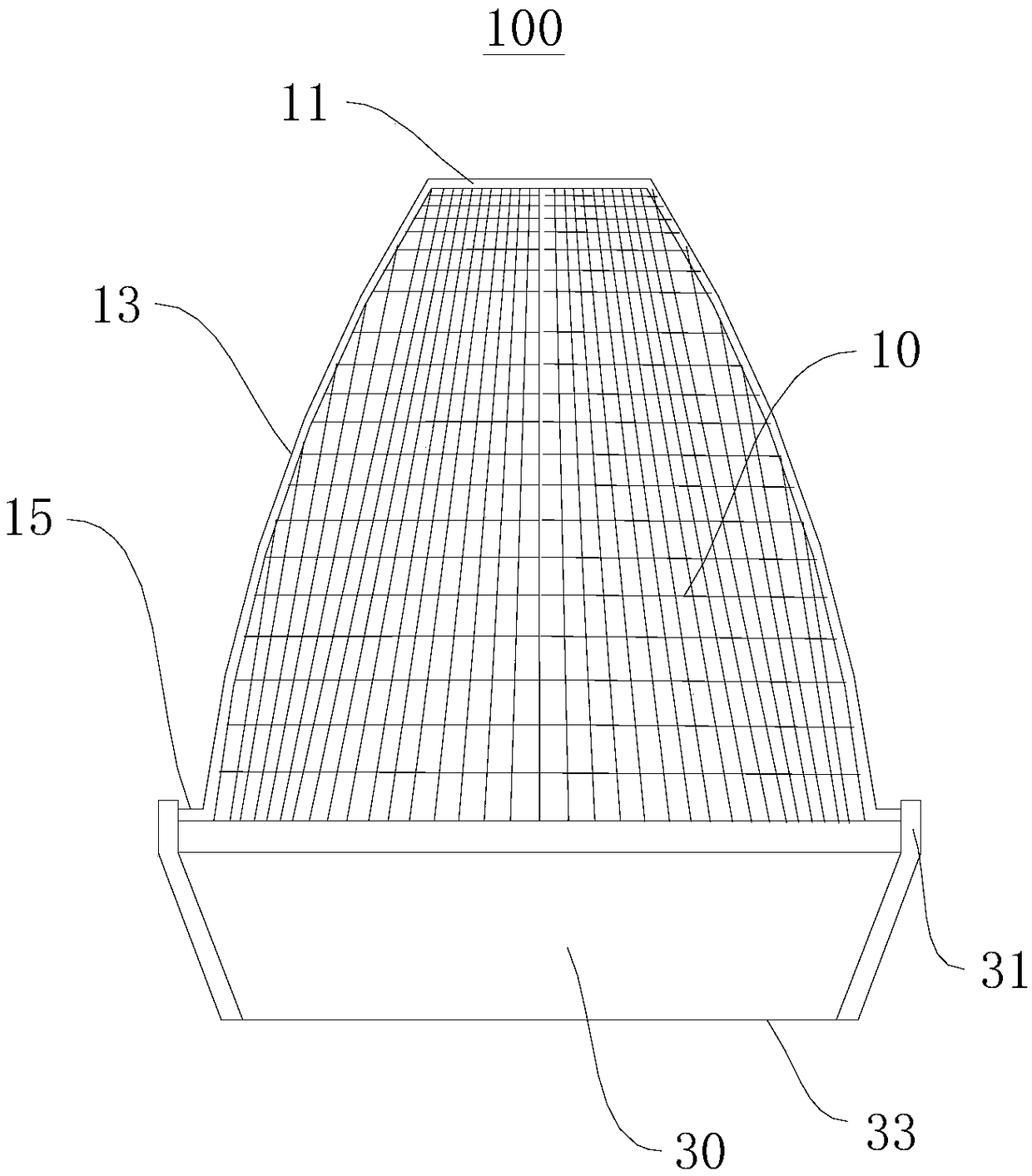

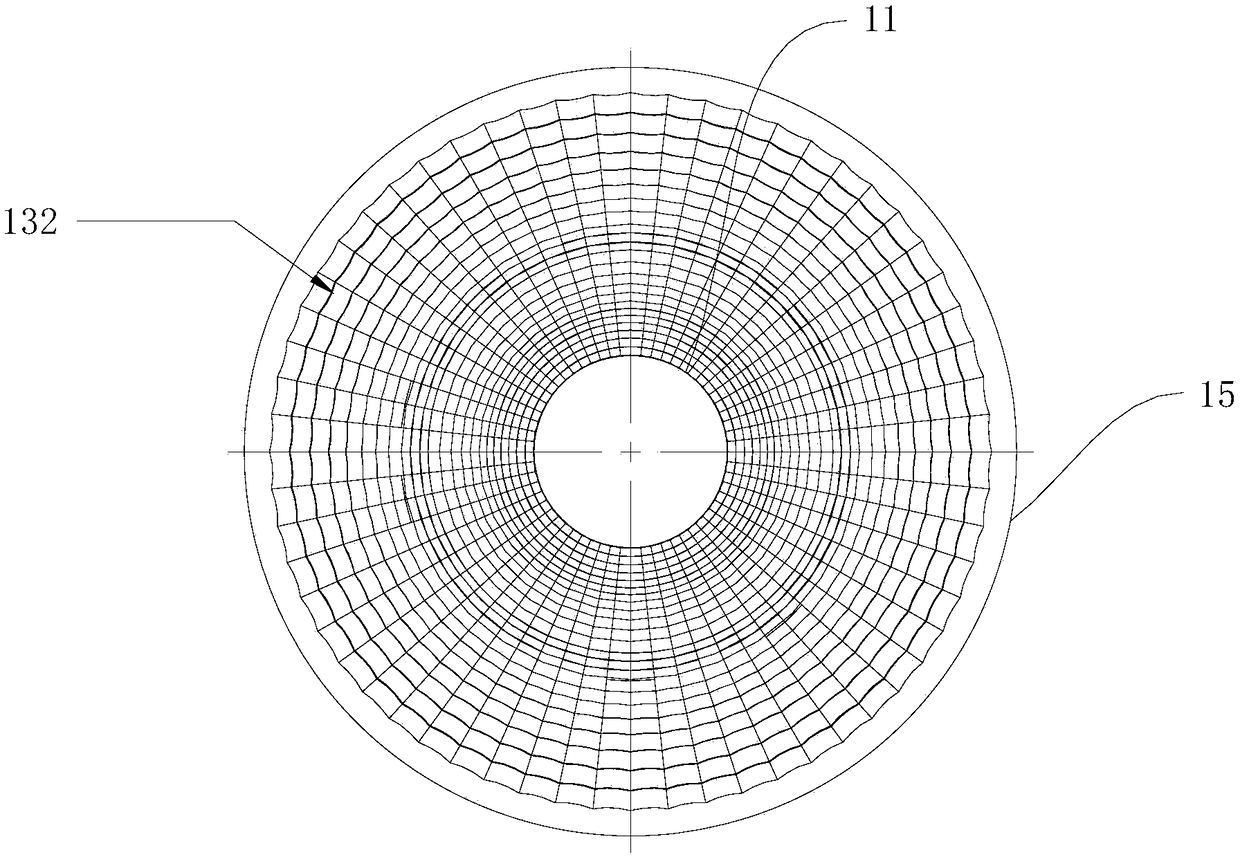

[0040] Please refer to Figure 1 to Figure 3 , this embodiment provides an LED reflector 100 without secondary facula, including:

[0041] A reflector 10, the reflector 10 includes a cover head 11, a cover body 13 and a cover platform 15, the cover head 11 and the cover platform 15 are respectively located at the two ends of the cover body 13, the cover head 11 is used to cover the LED lamp beads, the reflector 10 The size of the cross-sectional profile gradually increases from the side of the cover head 11 to the side of the cover platform 15;

[0042] A light receiving ring 30, the light receiving ring 30 includes a connecting portion 31 and a light receiving port 33, the connecting portion 31 is connected to the cover platform 15, and the cross-sectional profile size of the light receiving ring 30 gradually decreases from the connecting portion 31 to the light receiving port 33;

[0043] The light emitted by the LED lamp bead can be projected from the cover head 11 toward ...

Embodiment 2

[0062] This embodiment also provides an LED reflector 100 without secondary facula. The main differences between this embodiment and Embodiment 1 are:

[0063] The diameter of the outer circle of the cover table 15 is 68 mm, the diameter of the inner circle of the cover head 11 is 18.3 mm, and the height of the reflector 10 is 60.2 mm;

[0064] Correspondingly, the diameter of the inner circle of the connecting portion 31 is 68 mm, the diameter of the inner circle of the light receiving port 33 is 57.6 mm, and the height of the portion between the connecting portion 31 and the light receiving port 33 is 29.5 mm.

[0065] All the other structures can refer to embodiment 1.

[0066] Such dimensional design can also achieve the technical effect in Embodiment 1.

Embodiment 3

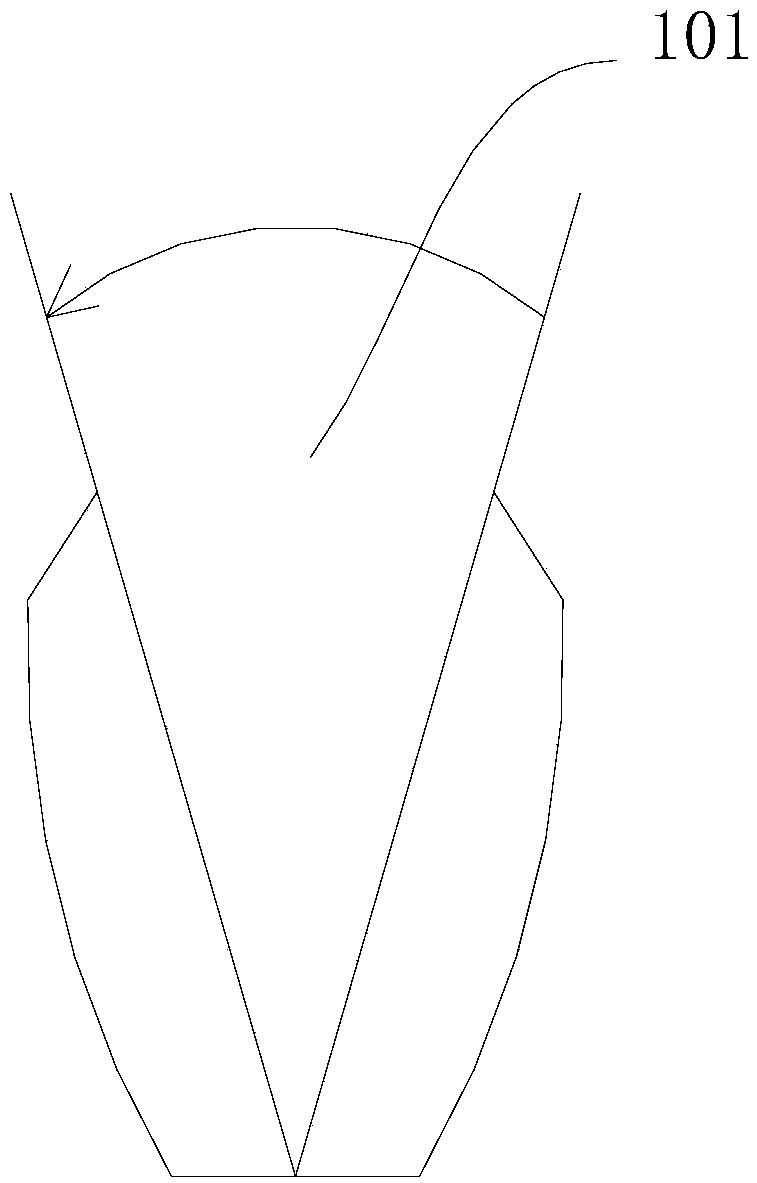

[0068] Please refer to Figure 4 , this embodiment provides a LED reflector 100 without secondary facula, the main difference between this embodiment and Embodiment 1 is:

[0069] The cover body 13 includes a first part 134 and a second part 136, the first part 134 is close to the cover head 11, the second part 136 is close to the cover platform 15, and the cut surface of the inner surface of the cover body 13 is outside the first part 134. The cut surface is an inner cut surface at the second part 136 , and the outer cut surface and the inner cut surface transition at the junction of the first part 134 and the second part 136 .

[0070] All the other structures can refer to embodiment 1.

[0071] Through the design of the cover body 13, the light emitted by the light source has the effect of converging towards the center when the first part 134 is in place. With the structure of the light receiving ring 30, it can also prevent the occurrence of secondary light spots like Emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com