Hydraulic jack upper cover sealing structure

A technology of hydraulic jack and sealing structure, applied in the direction of lifting device, etc., can solve the problems of easy wear of the sealing ring, deflection of the piston rod moving up and down, dust entering, etc., and achieve the effect of preventing wear of the sealing ring and good guiding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

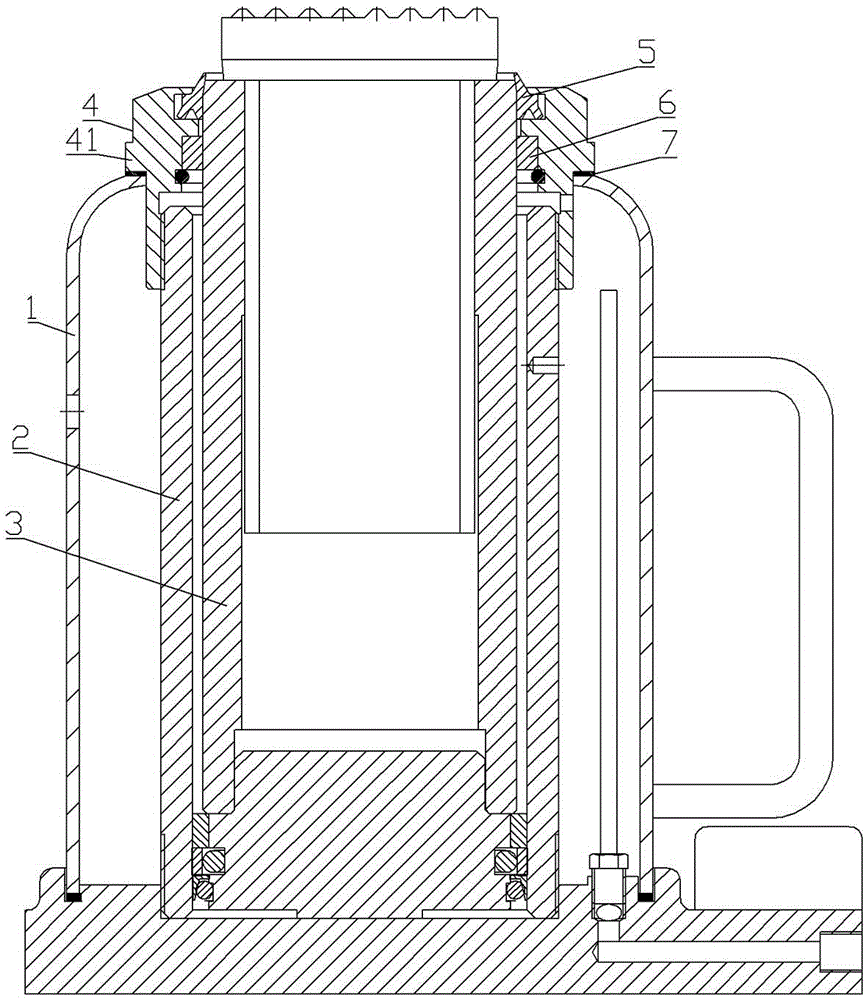

[0016] The sealing structure of the upper cover of the hydraulic jack includes a casing 1, an oil cylinder 2, a piston rod 3 and a top cap 4.

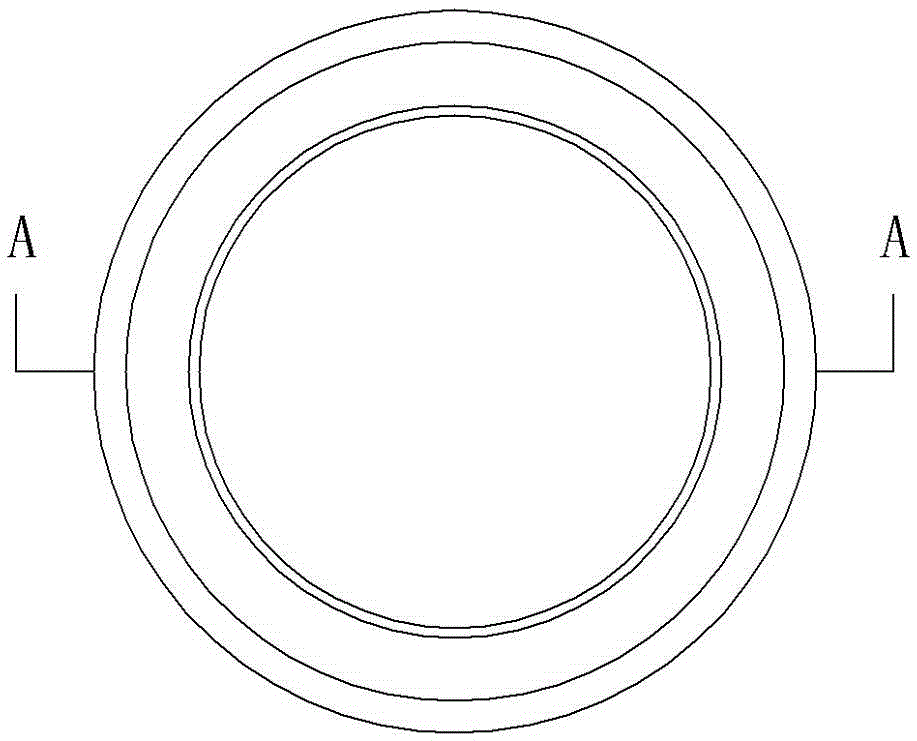

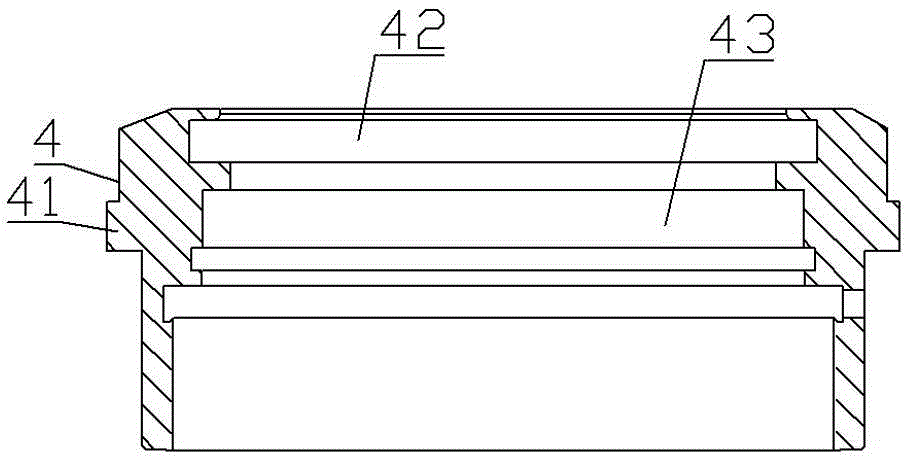

[0017] Oil cylinder 2 is arranged in shell 1. Piston rod 3 is arranged in oil cylinder 2, and its upper end stretches out from oil cylinder 2 and is positioned at top cap 4 upper end inner hole. The top cap 4 is in the shape of a sleeve with openings at both ends, and its outer edge is provided with an annular boss 41, which is threaded on the outer edge of the upper end of the oil cylinder 2 through the internal thread in the inner hole of the lower end. The groove A42 and the groove B43 are provided in sequence, and the lower annular surface of the annular boss 41 is against the shell 1 to provide positioning for the shell 1;

[0018] A dustproof ring 5 and a guide sleeve 6 are arranged between the top cap 4 and the piston rod 3 . The dustproof ring 5 is installed in the groove A42, and the guide sleeve 6 is installed in the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com