Method for designing section of sealing element of hydrogen fuel cell under temperature-induced shrinkage

A technology of fuel cells and design methods, applied in fuel cells, electrical components, computer-aided design, etc., can solve problems such as decreased sealing performance, failure to consider sealing parts, etc., and achieve good guiding significance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

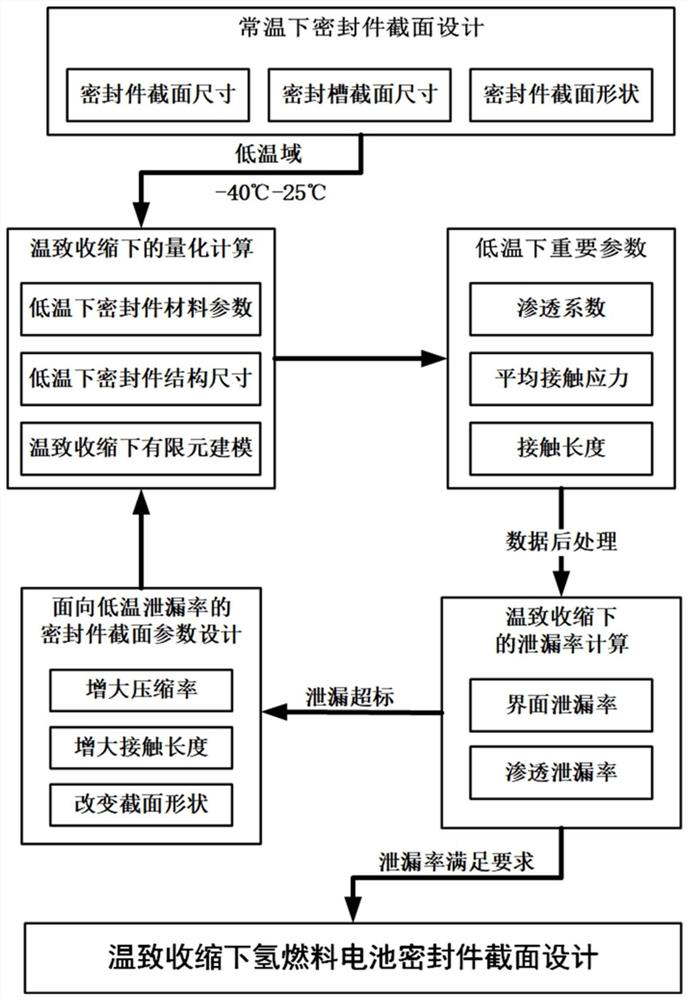

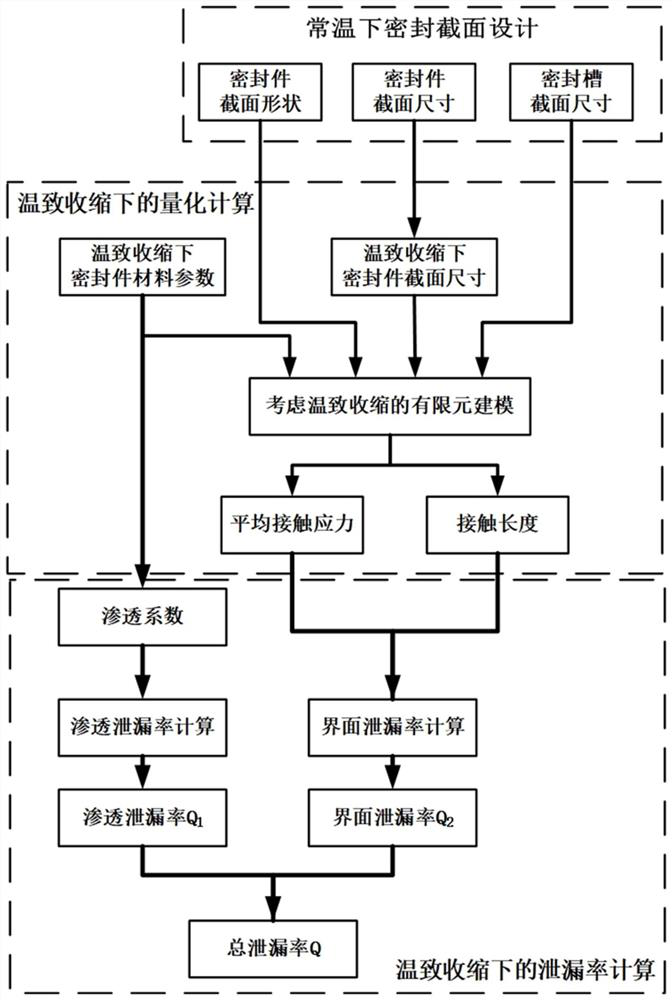

[0034] The present invention relates to a method of sealing optimizing design of seal sealing sections under temperature shrinkage, such as a fuel cell bipolar plate seal. figure 1 As shown, the method includes the following steps.

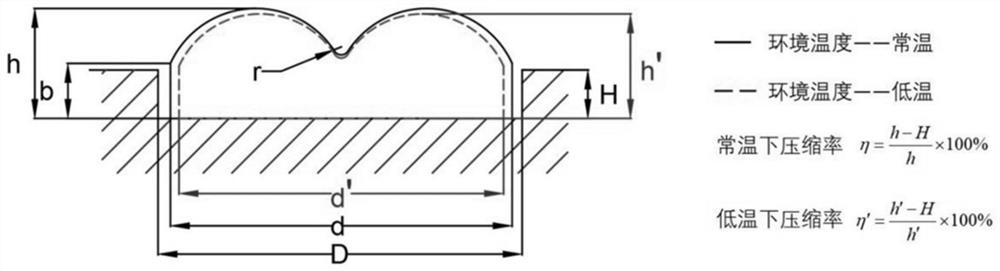

[0035] Step 1, sealing section design that is not considered at normal temperature is performed. The seal in this step is referred to as a seal A, and the sealing section can be used for an O-ring, a D-ring, a double peak, and the like, such as image 3 As shown, the present embodiment selects a bimodal seal ring, and the sealing material is a tri-pharmaceutical rubber, and the related parameter is selected as shown in Table 1.

[0036] Table 1 related parameters

[0037] Serial number parameter name Parameter code Parameter value 1 gas pressure P 0.2MPa 2 Work and ambient temperature t -40~25℃ 3 Friction coefficient μ 0.3 4 Sealing thickness h 0.6mm 5 Sealing width d 2mm 6 Sealing groove depth H 0....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap