Structure of guide rail slider of logistic sorting machine

A technology of guide rail sliders and sorting machines, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve problems such as high assembly requirements, increased sliding friction, and stuck sliders, so as to eliminate the influence of smooth guidance, The effect of reducing the requirements for machining accuracy and reducing the requirements for dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

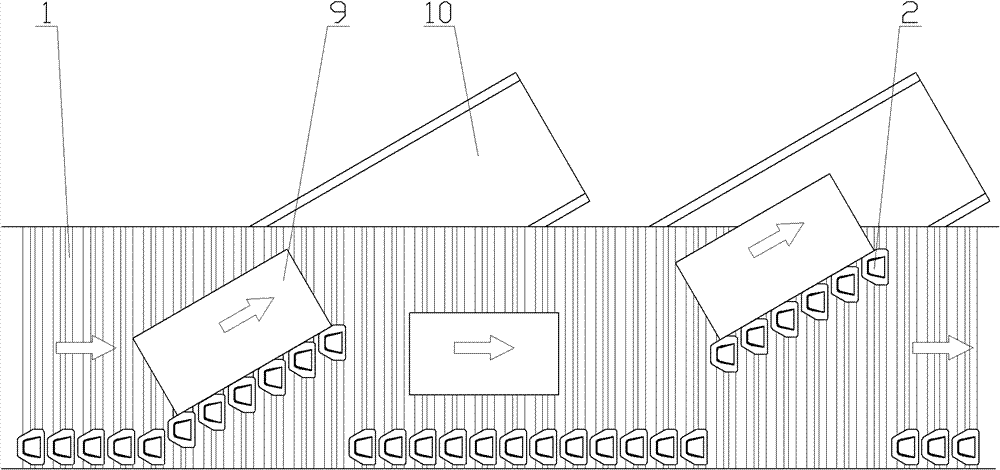

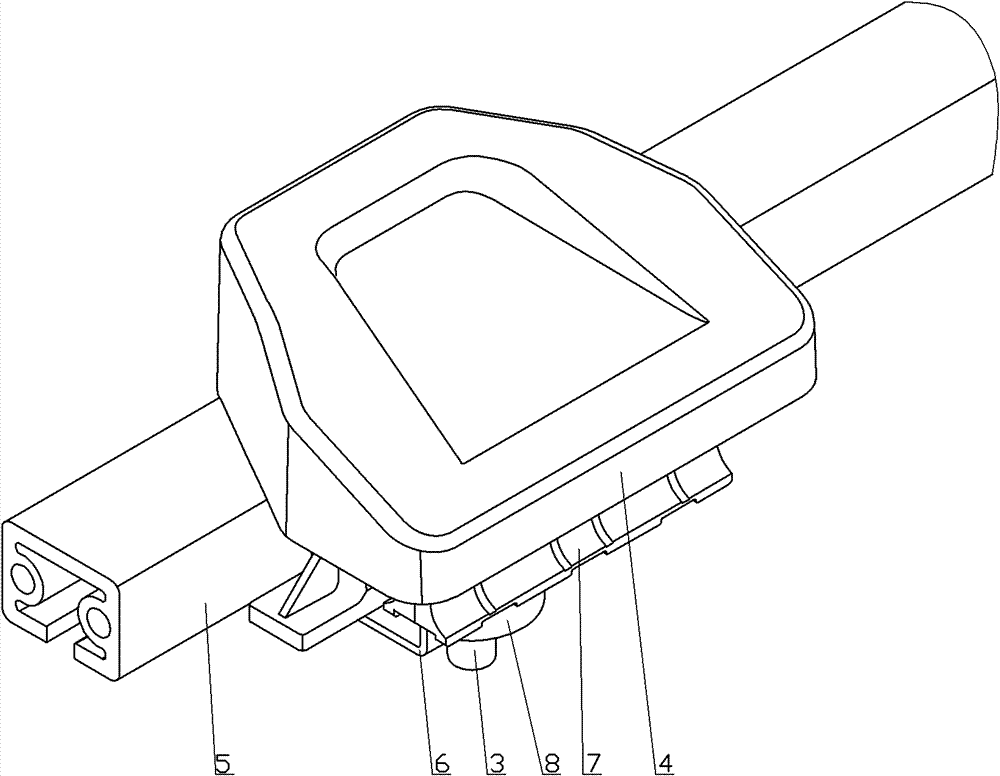

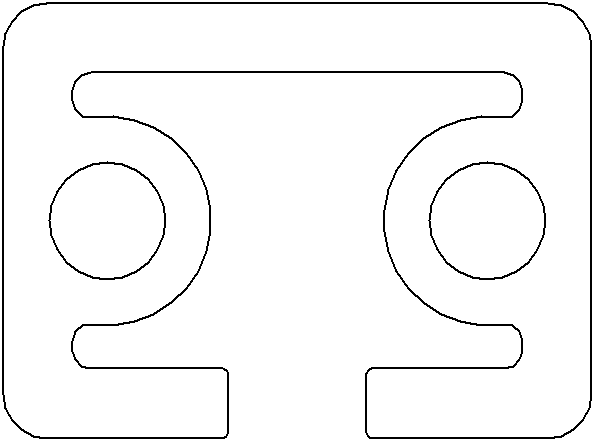

[0040] In the existing logistics sorting machine, the conveyor belt is composed of multiple parallel guide rails, the length of the guide rails is equal to the width of the conveyor belt, the existing guide rail 5 is an aluminum monorail, the cross section of the existing guide rail 5 is a hollow rectangle, and the shape of the chamber is a waist drum shape, with an opening at the bottom, every two existing guide rails 5 are a group, each group of existing guide rails 5 is equipped with an existing slider 4, the existing slider 4 is a trapezoidal box made of PA material, and its upper surface faces Downward tilting, a guide pin 3 is arranged below the existing slide block 4, the upper end of the guide pin 3 is screwed in the existing slide block 4, the lower end passes through the gap between the two existing guide rails 5, and is loaded into the existing guide rail 5 In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com