Pneumatic rotating guide propulsion drilling machine

A rotary steering, drilling rig technology, applied in directional drilling, drill bits, drilling equipment, etc., can solve the problem of inability to effectively control the horizontal steering of the drilling rig, and achieve the effect of improving drilling efficiency and enhancing the effect of steering and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

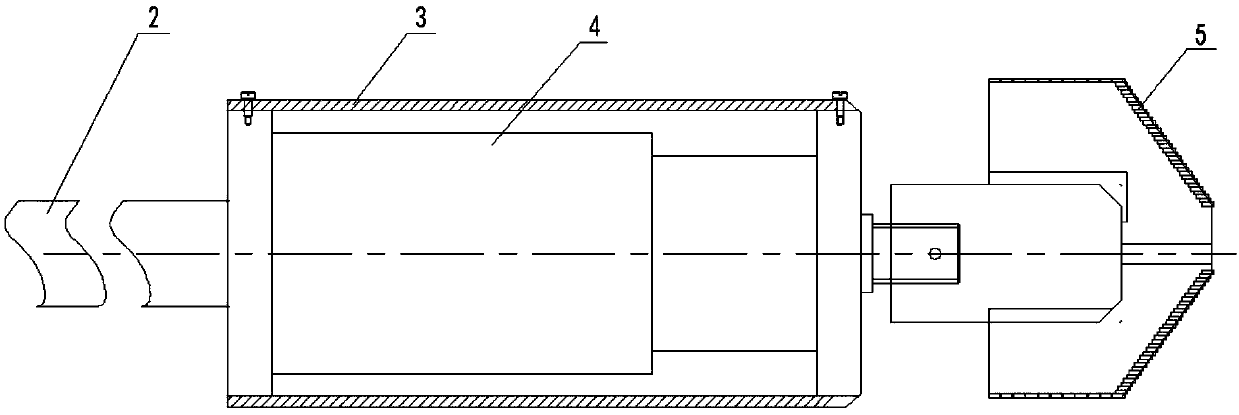

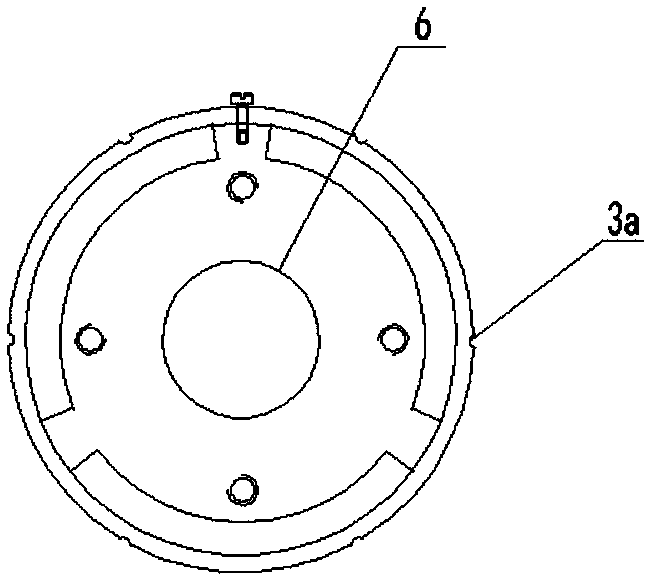

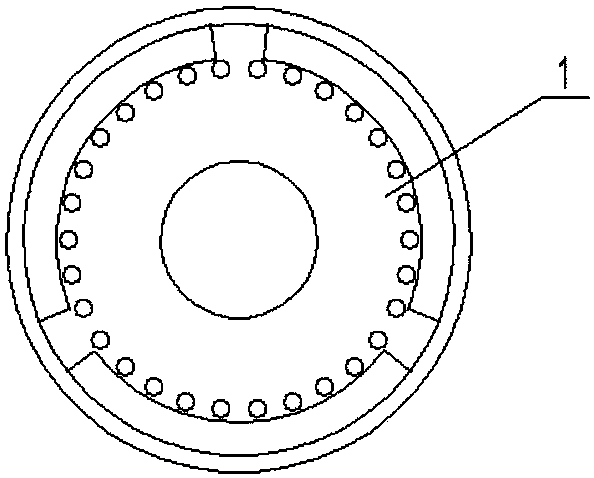

[0017] see figure 1 , figure 2 and image 3 In this embodiment, the structural form of the pneumatic rotary guiding and propelling drilling rig is as follows: a guiding and positioning sleeve 3 in the shape of a barrel is provided, an air motor 4 is fixedly arranged in the guiding and positioning sleeve 3, and the tail air intake duct 6 of the air motor 4 is guided The tail end of the positioning sleeve 3 protrudes and is externally connected to the air intake drill pipe 2. The front exhaust orifice plate 1 of the air motor 4 is fixedly installed on the front end of the guiding positioning sleeve 3 by using lugs. The rotating shaft of the air motor 4 is positioned on the guide The front end of cover 3 protrudes, and drill bit 5 is installed.

[0018] The diameter of the inner cavity of the guide positioning sleeve 3 is set to be larger than the outer diameter of the air motor 4, so that an axially penetrating annular channel is formed between the guide positioning sleeve 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com