Preparation method of magnetic orientation carbon nano tube reinforced glass fiber epoxy composite material

A carbon nanotube and glass fiber technology, which is applied in the field of preparation of magnetically oriented carbon nanotube reinforced glass fiber/epoxy composite materials, can solve problems such as agglomeration, achieve simple preparation process, stable product quality, and improve the effect of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of magnetically oriented carbon nanotube reinforced glass fiber / epoxy composite material, the specific steps are as follows:

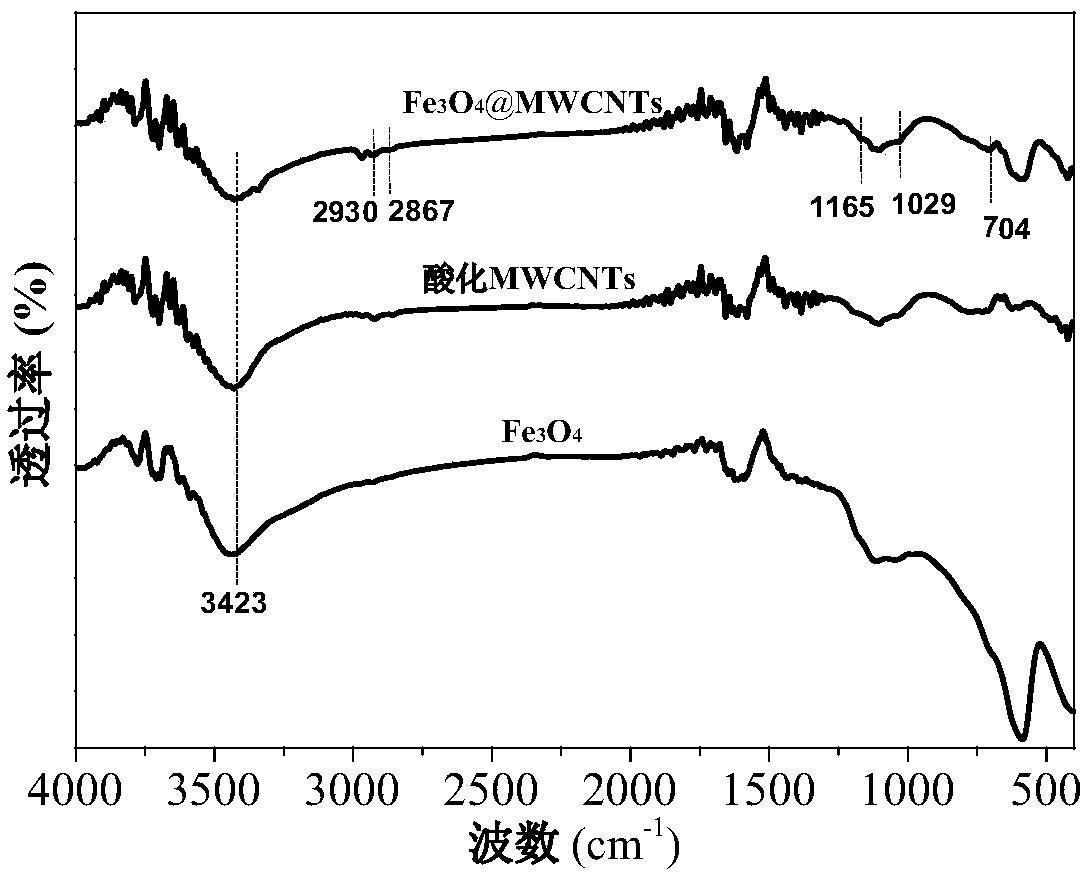

[0030] (1) Silanized carbon nanotubes: Weigh 0.5g of acid-oxidized multi-walled carbon nanotubes and add them into 0.05L of N,N'-dimethylformamide solvent, then weigh 0.01g of N,N'-diisopropyl Carbodiimide and 0.01g 1-hydroxybenzotriazole were added respectively, stirred for 5min and ultrasonicated for 30min to obtain a 10g / L carbon nanotube dispersion; then added 0.015g of γ-aminopropyltriethoxysilane, and Maintain mechanical stirring at a speed of 200 r / min for 24 hours; wash with absolute ethanol for 3 times and filter to obtain silanized carbon nanotubes.

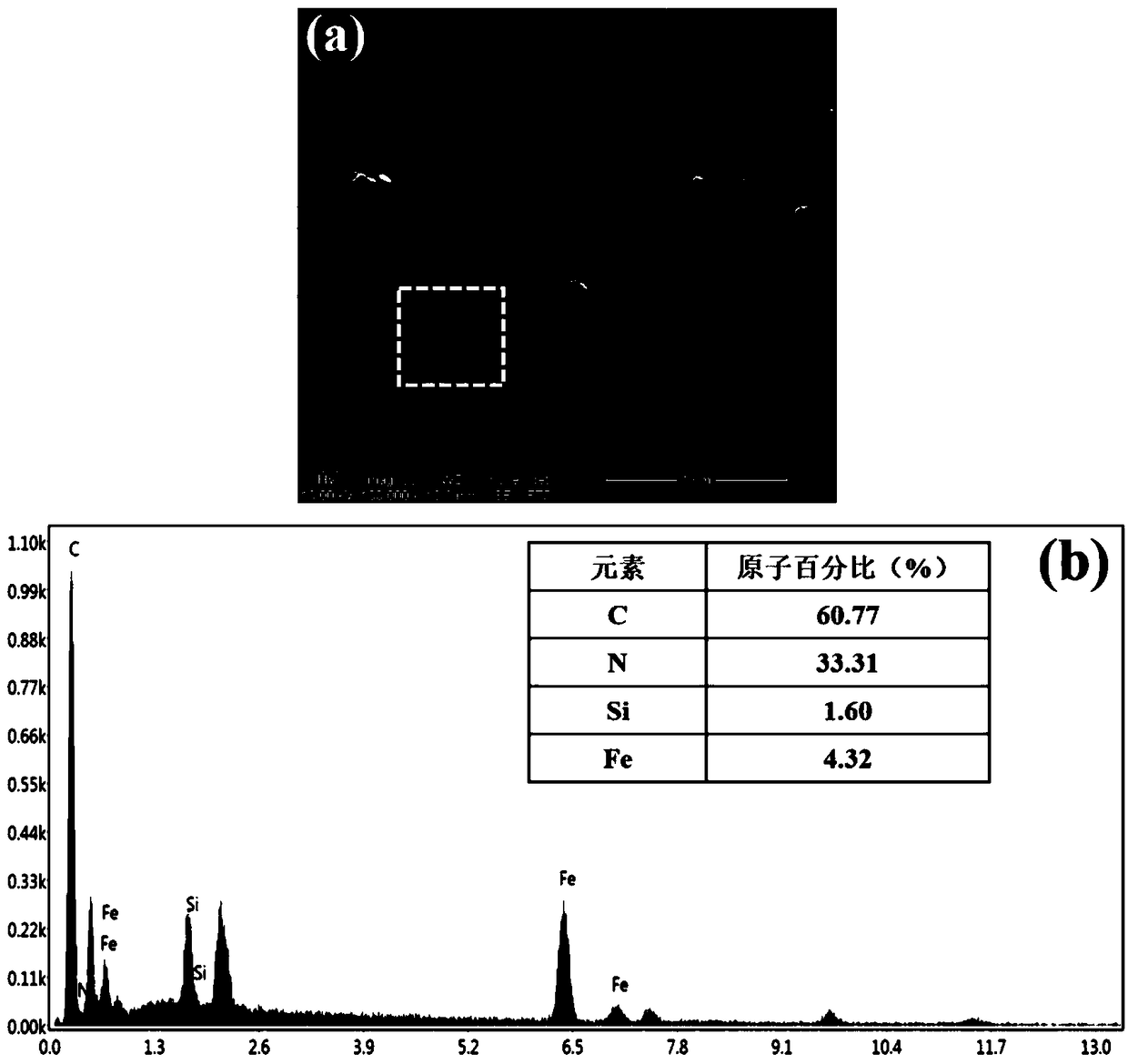

[0031] (2) Carbon nanotubes grafted ferroferric oxide magnetic balls: ultrasonically disperse the silanized carbon nanotubes in step (1) in 0.05L absolute ethanol to obtain a 10g / L silanized carbon nanotube dispersion; Then add 0.55g of ferroferric oxide magnetic bal...

Embodiment 2

[0036] A preparation method of magnetically oriented carbon nanotube reinforced glass fiber / epoxy composite material, which is different from Example 1 in that the acidified carbon nanotube described in step (1) becomes 1.2g, and the N, N'-diisopropylcarbodiimide and 1-hydroxybenzotriazole become 0.024g respectively, and described gamma-aminopropyltriethoxysilane becomes 0.03g; Described in step (2) The mass of the ferroferric oxide magnetic ball becomes 1.8 g; the dispersant becomes 0.3 g of polyvinyl butyral (B60H) in step (3).

Embodiment 3

[0040] A preparation method of magnetically oriented carbon nanotube reinforced glass fiber / epoxy composite material, which is different from Example 1 in that the acidified carbon nanotube described in step (1) becomes 0.6g, and the organic solvent Become dichloromethane, described carbodiimide type condensing agent becomes the 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC) of 0.018g, described silane di The gamma-aminoethylaminopropyltriethoxysilane that joint agent becomes 0.03g; The ferriferromagnetic ball quality described in step (2) becomes 1.2g, and the diameter of magnetic ball becomes about 300nm; Step (3) The dispersant becomes 0.24g of alkylphenol polyoxyethylene ether; the epoxy resin becomes a viscosity of 1000~1800mPa·s glycidyl ester epoxy resin, and the consumption is 41.6g; the curing Agent becomes 593 solidifying agent, consumption is 8.4g; Described glass fiber material becomes surface density 400g / m 2 The square cloth, consumption is 160g, lays 4 lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com