Preparation method of oriented shell-core structural superfine composite fiber

An ultra-fine composite fiber, orientation technology, applied in the direction of fiber processing, fiber chemical characteristics, cellulose/protein conjugated rayon, etc., can solve the problems of fiber orientation degree, yarn bundle length, yield, and mechanical properties gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

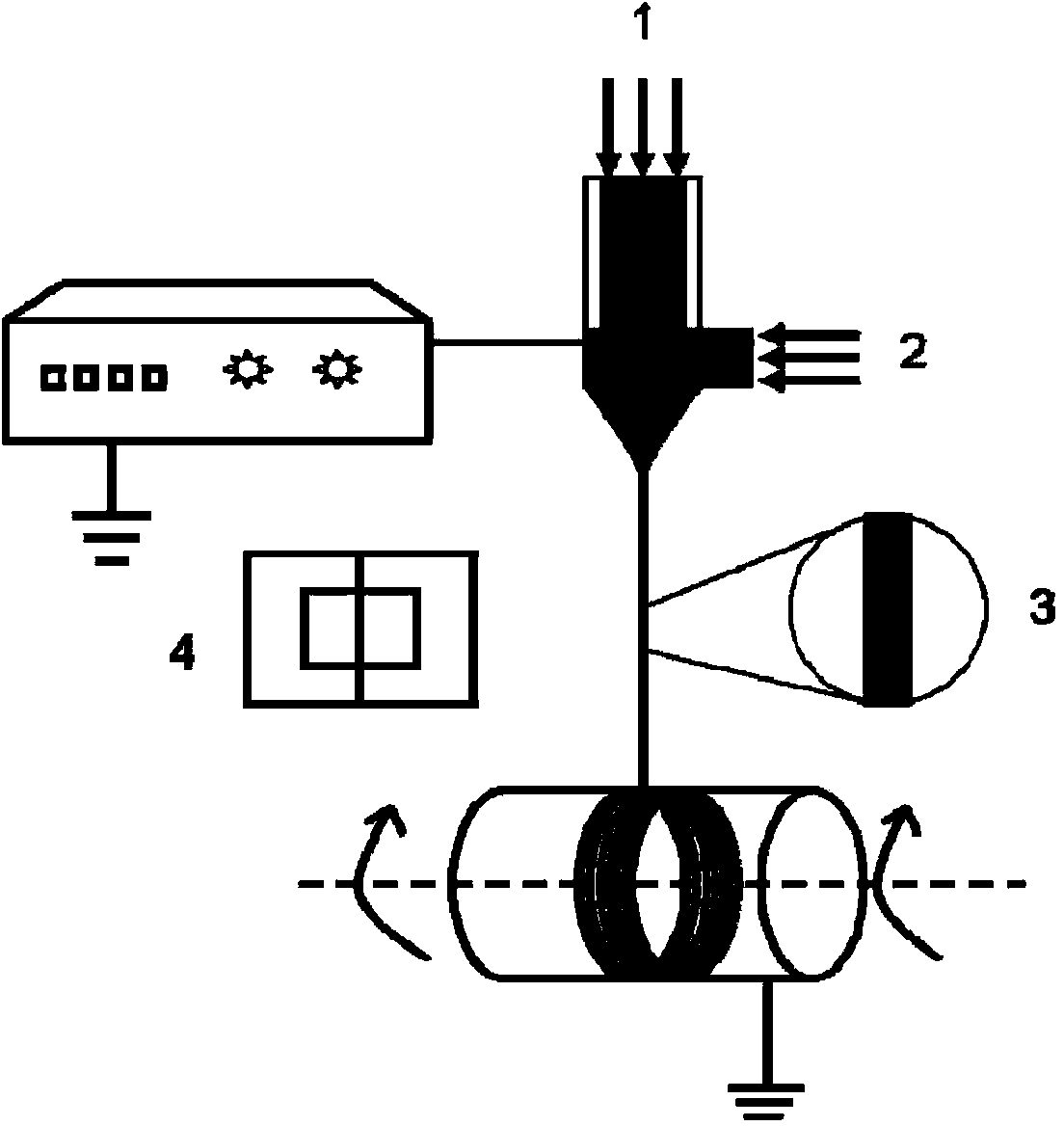

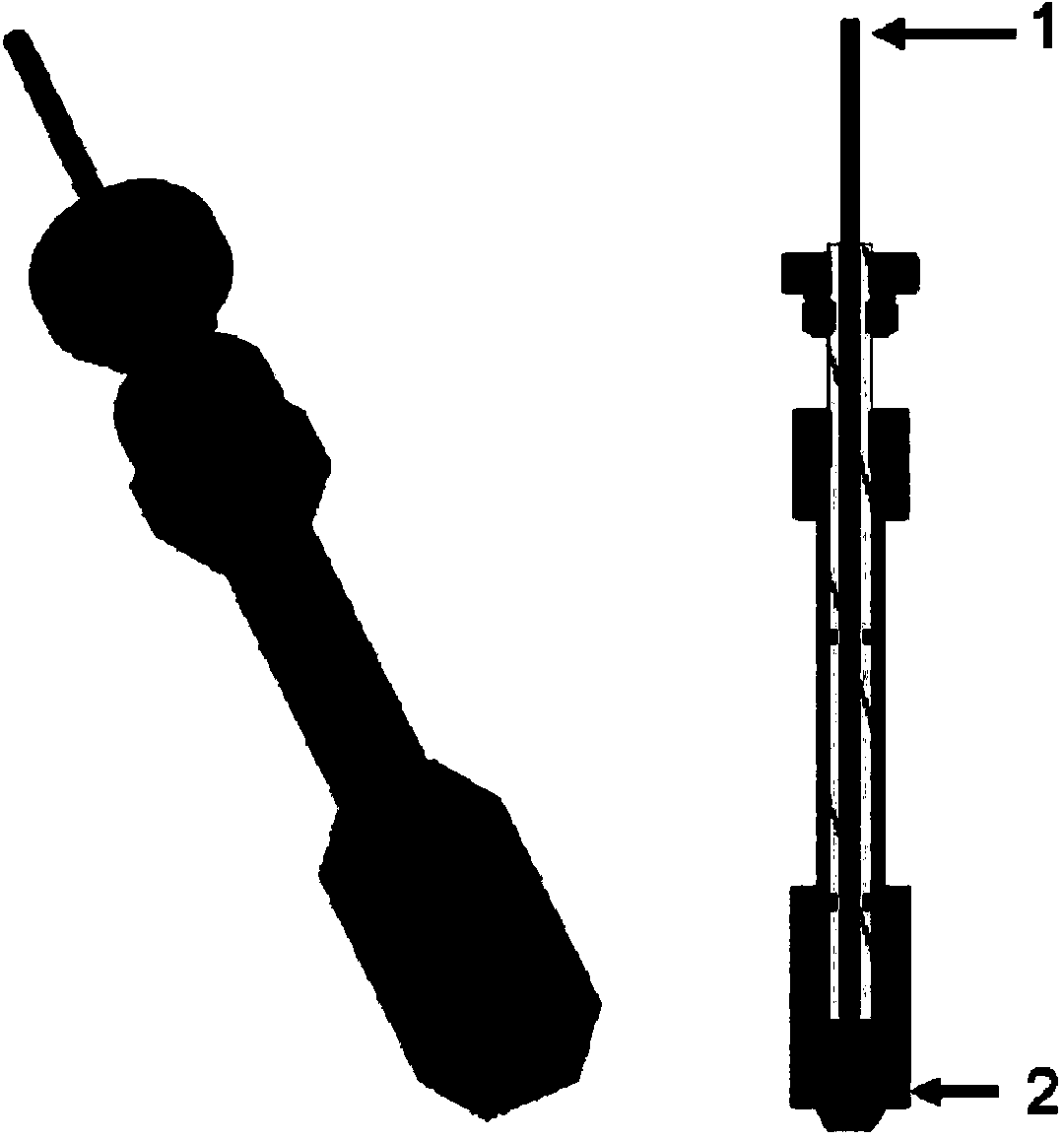

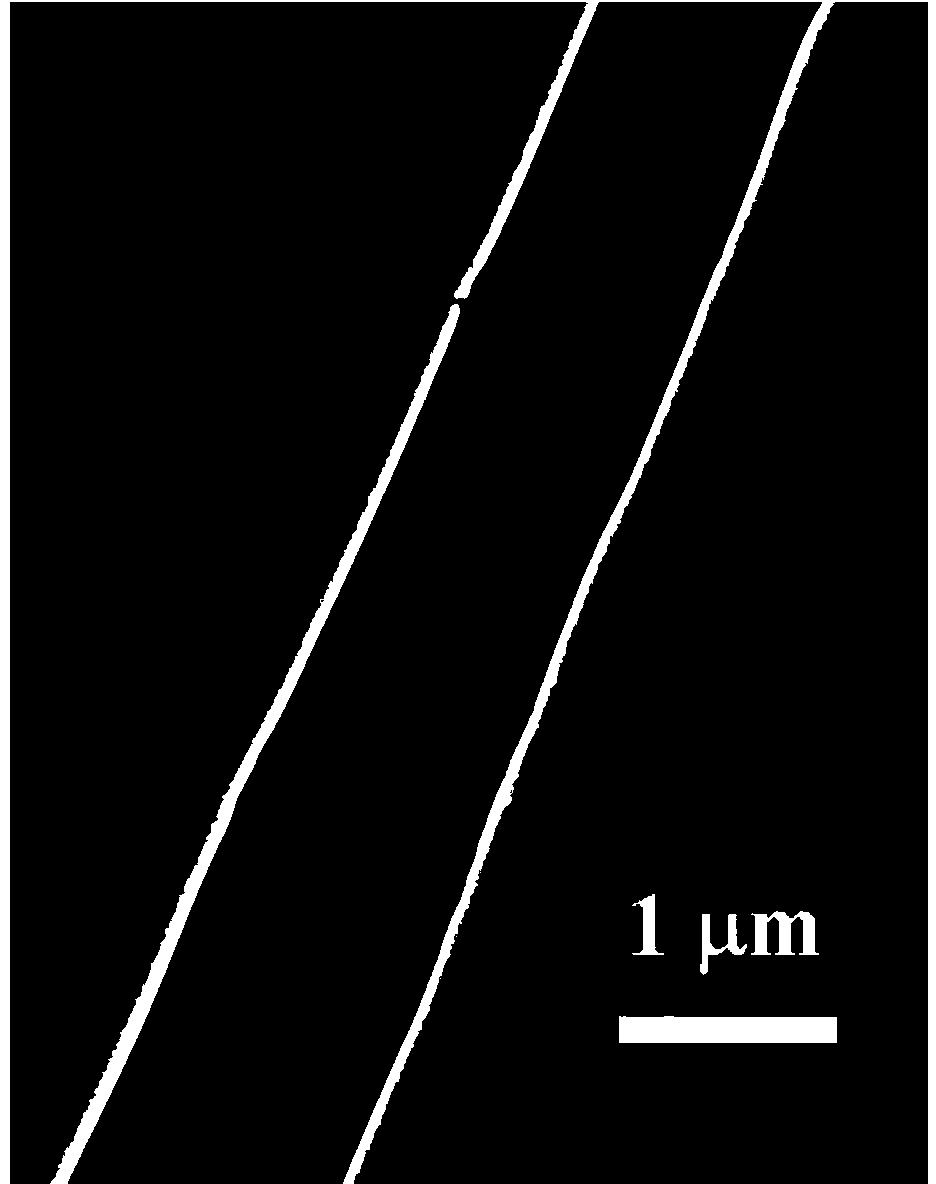

Embodiment 1

[0041] Dissolve 0.1g of hyaluronic acid in 10ml of ammonia water (concentration 25-28%) and trifluoroethanol (TFE) mixed solvent (volume ratio of ammonia water / TFE = 2 / 1) at room temperature, and stir for 24 hours to obtain a mass concentration of 1% (g / ml) shell spinning solution; 0.4g polylactic acid (PLLA, intrinsic viscosity 1.5) and 0.1g ultra-high molecular weight PEO (molecular weight greater than 5,000,000Da) were dissolved in 10g trifluoroethanol at room temperature In the solvent, stir for 24h to obtain the PLLA core layer spinning solution. Use a 10ml syringe, coaxial spinnerets with inner and outer diameters of 2.5 and 3.5 mm, such as figure 2 As shown, the hyaluronic acid shell spinning solution and the PLLA core spinning solution were respectively extracted and fixed on the "jet stable coaxial electrospinning" device as shown in Fig. figure 1 Electrospinning was performed as shown, and the spinning parameters were: voltage 12kV, receiving distance 30cm, ambien...

Embodiment 2

[0043] Dissolve 0.3 g of chitosan (molecular weight 900,000 to 1,000,000 Da) in 10 g of 3% acetic acid aqueous solution at room temperature, and stir for 24 hours to obtain a shell spinning solution with a mass concentration of 3% (g / ml); 0.4g PLLA (intrinsic viscosity 1.5) and 0.1g ultra-high molecular weight PEO (molecular weight greater than 5,000,000Da) were dissolved in 10g trifluoroethanol solvent at room temperature, and stirred for 24 hours to obtain PLLA core layer spinning solution. Use a 10ml syringe, coaxial spinnerets with inner and outer diameters of 2.5 and 3.5 mm, such as figure 2 As shown, the chitosan shell spinning solution and the PLLA core spinning solution were respectively extracted and fixed on the "jet stable coaxial electrospinning" device as shown in Fig. figure 1 Electrospinning is performed as shown, and the spinning parameters are: voltage 9kV, receiving distance 20cm, ambient temperature 20°C, and ambient humidity 32%. The injection rate of th...

Embodiment 3

[0045] Dissolve 0.3g of gelatin in 10ml of trifluoroethanol at room temperature, stir for 24h until the solute is completely dissolved, and obtain a 3% (g / ml) shell layer uniform transparent solution; mix 0.4g PLLA (intrinsic viscosity 1.5) with 0.1 g of ultra-high molecular weight PEO (molecular weight greater than 5,000,000Da) was dissolved in 10 g of trifluoroethanol solvent at room temperature, and stirred for 24 hours to obtain a PLLA core layer spinning solution. Use a 10ml syringe, coaxial spinnerets with inner and outer diameters of 2.5 and 3.5 mm, such as figure 2 As shown, the gelatin shell spinning solution and the PLLA core spinning solution were extracted respectively, and fixed on the "jet stable coaxial electrospinning" device as shown in Fig. figure 1 Electrospinning is performed as shown, and the spinning parameters are: voltage 4.85kV, receiving distance 21cm, ambient temperature 25°C, and ambient humidity 45%. The injection rate of the core layer solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com