Preparation method of nerve conduit material based on polyhydroxyalkanoate/gelatin electrospun nanofibers

A technology of polyhydroxyalkanoate and nerve conduit, which is applied in the field of preparation of nerve conduit materials, can solve the problems of insufficient donor area and limitation of autologous transplantation sources, and achieves the effects of improving biocompatibility and electrospinning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

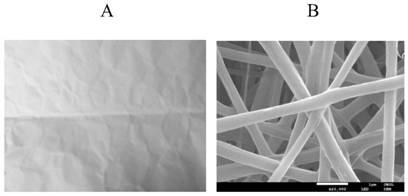

[0041] The nerve conduit material of polyhydroxyalkanoate / gelatin composite fiber is prepared according to the following method:

[0042] (1) At room temperature, weigh 0.17g of hyaluronic acid powder and 0.51g of chitosan, place chitosan in 50g of deionized water and put it in a low-temperature reactor at 4°C and stir evenly, then add dilute Add glacial acetic acid until the solution is clear, adjust the pH of the solution to 7.1 with β-sodium glycerophosphate, then add 5 mg of genipin and 0.17 g of hyaluronic acid and stir for 12 hours to prepare a CS-HA injection hydrogel solution for use;

[0043] (2) making the surface of the tubular mold (plastic tube) immersed in 70% sucrose bonding liquid with a concentration of 70% by mass, so that the bonding liquid is evenly distributed on the surface of the tubular mold;

[0044](3) Prepare a gelatin aqueous solution with a mass percentage concentration of 5%, extract 1 mL, add 0.4 g of alkyl glycosides and 32.34 g of chloroform, h...

Embodiment 2

[0052] The nerve conduit material of polyhydroxyalkanoate / gelatin composite fiber is prepared according to the following method:

[0053] (1) At room temperature, weigh 0.17g of hyaluronic acid powder and 0.51g of chitosan, place chitosan in 50g of deionized water and put it in a low-temperature reactor at 4°C and stir evenly, then add dilute Add glacial acetic acid until the solution is clear, adjust the pH of the solution to 7.1 with β-sodium glycerophosphate, then add 10 mg of genipin and 0.17 g of hyaluronic acid and stir for 12 hours to prepare a CS-HA injection hydrogel solution for use;

[0054] (2) making the surface of the tubular mold (plastic tube) immersed in a sucrose bonding solution with a mass percentage concentration of 60%, so that the bonding solution is evenly distributed on the surface of the tubular mold;

[0055] (3) Prepare a gelatin aqueous solution with a mass percentage concentration of 15%, extract 1 mL, add 0.4 g of alkyl glycosides and 32.34 g of ...

Embodiment 3

[0062] The nerve conduit material of polyhydroxyalkanoate / gelatin composite fiber is prepared according to the following method:

[0063] (1) At room temperature, weigh 0.17g of hyaluronic acid powder and 0.51g of chitosan, place chitosan in 50g of deionized water and put it in a low-temperature reactor at 4°C and stir evenly, then add dilute Add glacial acetic acid until the solution is clear, adjust the pH of the solution to 7.1 with β-sodium glycerophosphate, then add 5 mg of genipin and 0.17 g of hyaluronic acid and stir for 12 hours to prepare a CS-HA injection hydrogel solution for use;

[0064] (2) making the surface of the tubular mold (plastic tube) immersed in 70% sucrose bonding liquid with a concentration of 70% by mass, so that the bonding liquid is evenly distributed on the surface of the tubular mold;

[0065] (3) Prepare a gelatin aqueous solution with a concentration of 20% by mass, extract 1 mL, add 0.6 g of alkyl glycosides and 32.34 g of chloroform, homogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com