Preparation method of nerve conduit material based on polyhydroxyalkanoate/sodium alginate electrospun nanofibers

A polyhydroxyalkanoate and nerve conduit technology, which is applied in the field of nerve conduit materials and their preparation, can solve the problems of limitation, insufficient source of autologous transplantation and donor area, etc., and achieve the effect of improving electrospinning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

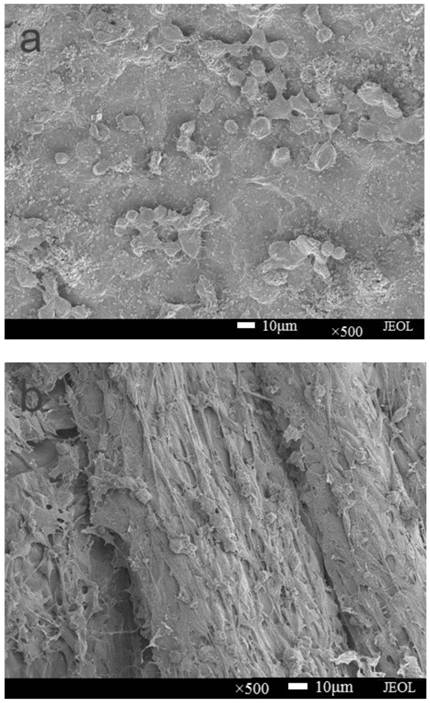

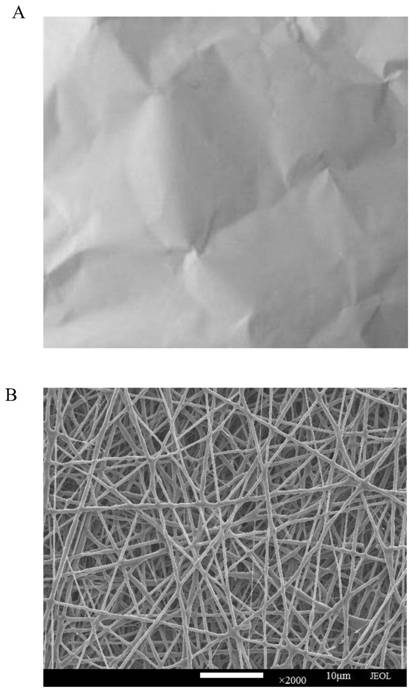

Image

Examples

Embodiment 1

[0039] The nerve guide material of polyhydroxyalkanoate / sodium alginate composite fiber is prepared according to the following method:

[0040] (1) carding chitosan fibers to form directional chitosan fibers;

[0041] (2) making the tubular mold (plastic tube) surface dipped in the sucrose bonding solution that mass percent concentration is 70%, and roll-coating on the surface of the oriented chitosan fiber, the chitosan fiber is evenly distributed on the tubular mold surface ;

[0042] (3) immerse the tubular mold formed with the chitosan fiber layer on the surface in the gelatin aqueous solution of 10% by mass percentage concentration, place it for a period of time, take out the tubular mold and dry it at room temperature, so that the chitosan fiber A gelatin layer is formed on the surface of the layer, and this step can be repeated several times, so that the thickness of the gelatin layer on the chitosan fiber layer surface reaches 1mm, and a tubular mold having a nerve gu...

Embodiment 2

[0049] The nerve guide material of polyhydroxyalkanoate / sodium alginate composite fiber is prepared according to the following method:

[0050] (1) carding chitosan fibers to form directional chitosan fibers;

[0051] (2) making the surface of the tubular mold (plastic tube) immersed in the sucrose bonding solution with a concentration mass concentration of 70%, and rolling coating on the surface of the oriented chitosan fiber, so that the chitosan fiber is evenly distributed on the surface of the tubular mold;

[0052] (3) will form the tubular mold that has chitosan fiber layer on the surface and be immersed in the gelatin aqueous solution of 10% in mass concentration, place for a period of time, take out tubular mold and dry at room temperature, so that on the surface of chitosan fiber layer Form the gelatin layer, this step can be repeated several times, make the thickness of the gelatin layer on the chitosan fiber layer surface reach 1mm, must form the tubular mold that h...

Embodiment 3

[0058] The nerve guide material of polyhydroxyalkanoate / sodium alginate composite fiber is prepared according to the following method:

[0059] (1) carding chitosan fibers to form directional chitosan fibers;

[0060] (2) making the surface of the tubular mold (plastic tube) immersed in the sucrose bonding solution with a concentration mass concentration of 70%, and rolling coating on the surface of the oriented chitosan fiber, so that the chitosan fiber is evenly distributed on the surface of the tubular mold;

[0061] (3) will form the tubular mold that has chitosan fiber layer on the surface and be immersed in the gelatin aqueous solution of 10% in mass concentration, place for a period of time, take out tubular mold and dry at room temperature, so that on the surface of chitosan fiber layer Form the gelatin layer, this step can be repeated several times, make the thickness of the gelatin layer on the chitosan fiber layer surface reach 1mm, must form the tubular mold that h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com