Electrostatic spinning method for controlling assembly of nanofibers with two-dimensional and three-dimensional structures

A nanofiber, three-dimensional structure technology, applied in fiber processing, textiles and papermaking, filament/wire forming, etc., can solve the problems of only a few millimeters, increased electrospinning time, long operation time, etc., and achieves easy operation control, electrospinning effect is good, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

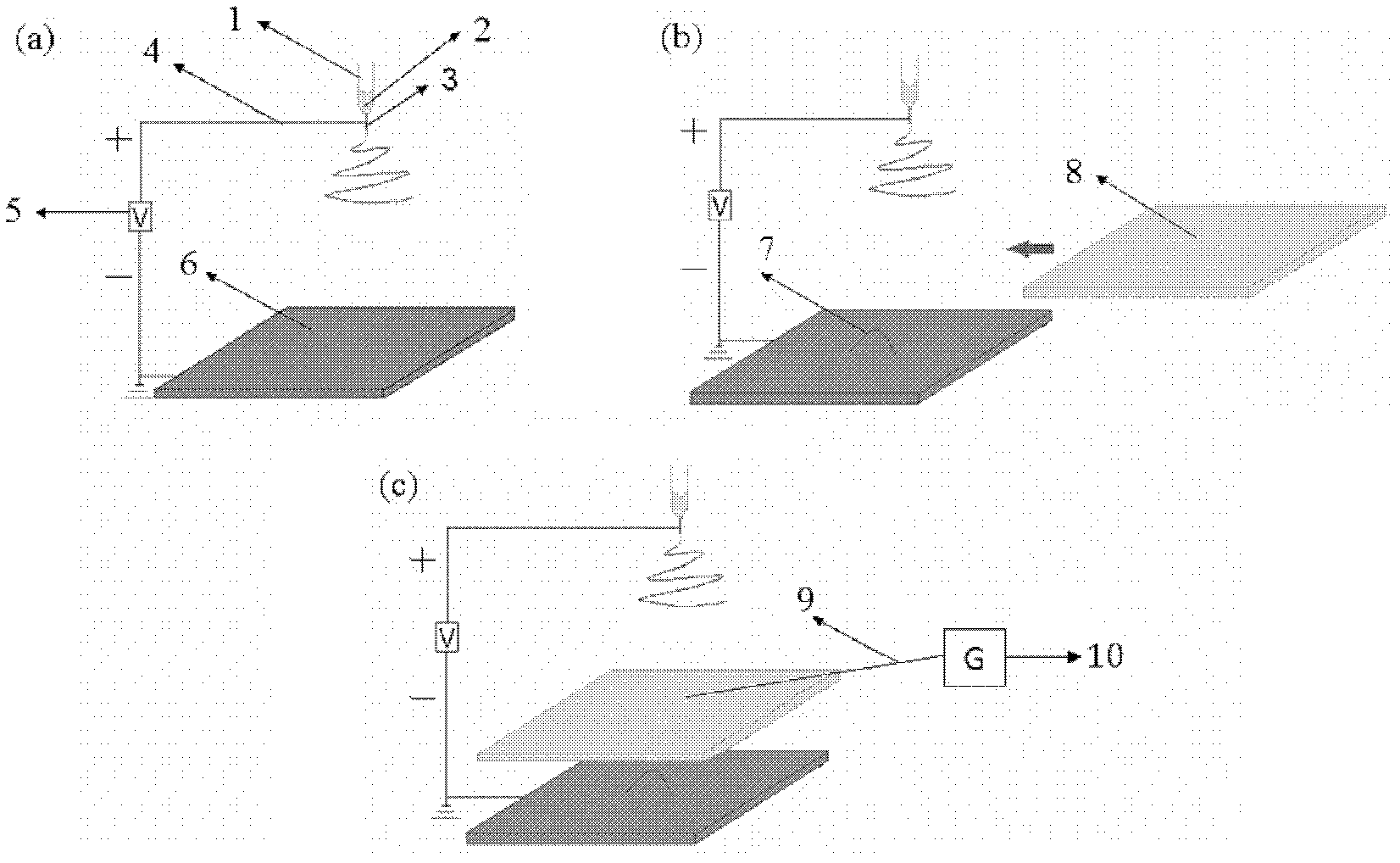

Method used

Image

Examples

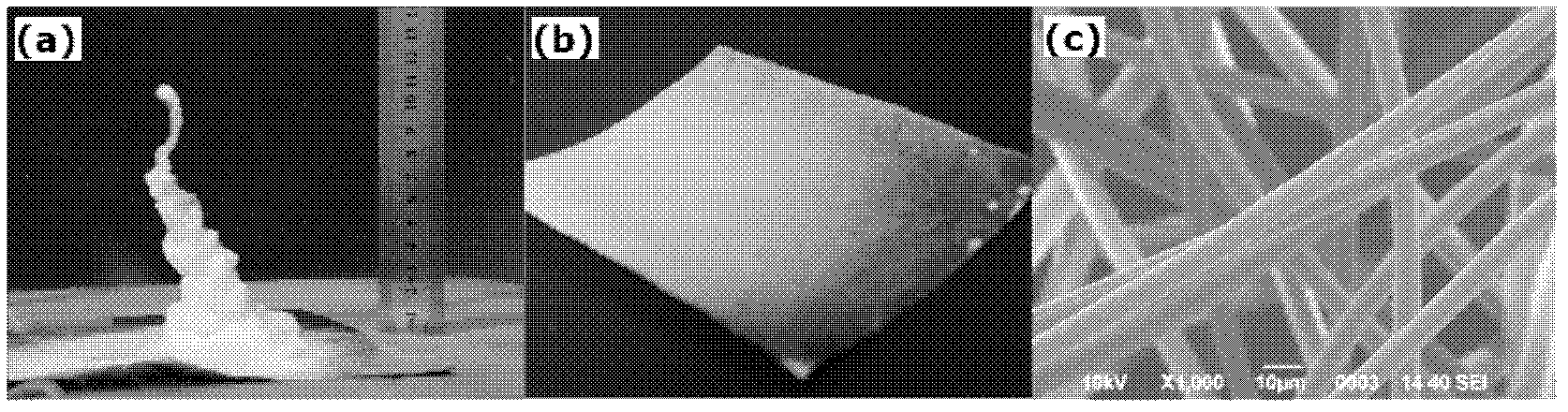

Embodiment 1

[0017]The spinning solution selected in this embodiment is a polystyrene (Polystyrene, PS) solution with a mass fraction of 15%, and 3 grams of polystyrene powder are dissolved in 17 grams of dimethylformamide (dimethylformamide, DMF) and tetrahydrofuran ( tetrahydrofuran, THF) in a mixed solution (the mass ratio of DMF and THF is 1:1, each 8.5 grams), the mixed solution was stirred with a magnetic stirrer for 4 hours and then allowed to stand for 1 hour to obtain polyphenylene with a mass fraction of 15%. Ethylene electrospinning precursor solution; the polystyrene electrospinning precursor solution with a mass fraction of 15% is injected into a syringe 1 connected to a high-voltage DC power supply 5 (the positive pole of the spinning voltage is about 20kV); the spinning needle 3 The distance between the grounded aluminum foil 6 is 14-16 cm, and the power is turned on at room temperature (10°C-20°C) for spinning; due to the rapid volatilization of the solvent, especially tetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com