Carbon fiber manufacturing assembly line

A technology of carbon fiber manufacturing and assembly line, which is applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of insufficient fiber molecular orientation, carbon fiber does not have strength, and fiber drafting is not possible, so as to prevent unnecessary oxidation and energy consumption The effect of reducing and increasing the degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

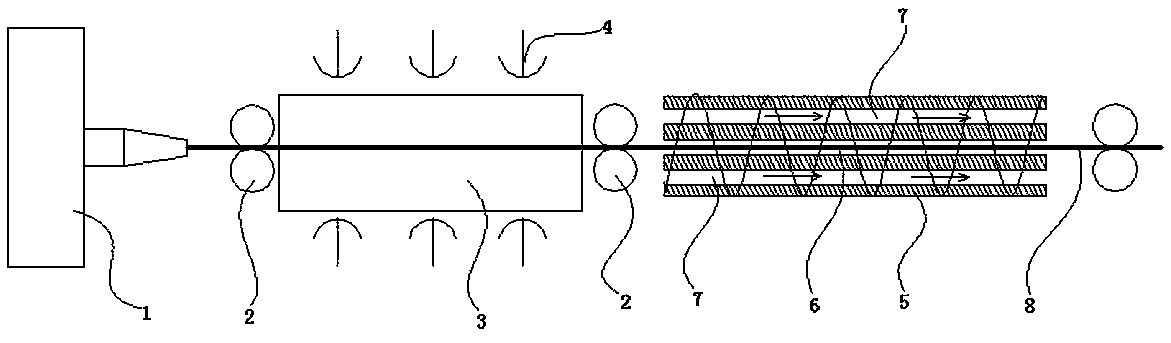

[0023] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0024] Such as figure 1 As shown, a carbon fiber manufacturing assembly line includes: a raw silk production device 1, a pre-oxidation device, a carbonization device and a graphitization device (not shown) arranged in sequence along the assembly line, and the pre-oxidation device includes a graphite soaking chamber 3 and is arranged in a The drafting mechanism at both ends of the graphite soaking chamber 3 is provided with a flame source 4 around the side of the graphite soaking chamber 3 . The graphite soaking chamber 3 is set to cooperate with the flame source 4. The good thermal conductivity of graphite can achieve the effect of soaking he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com