Liquid metal container bottom heating device and application thereof

A liquid metal and container bottom technology, which is applied in metal processing equipment, casting melt containers, casting equipment, etc., can solve the problems of complex and expensive equipment, and achieve the effects of convenient use, high thermal efficiency, and improved heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

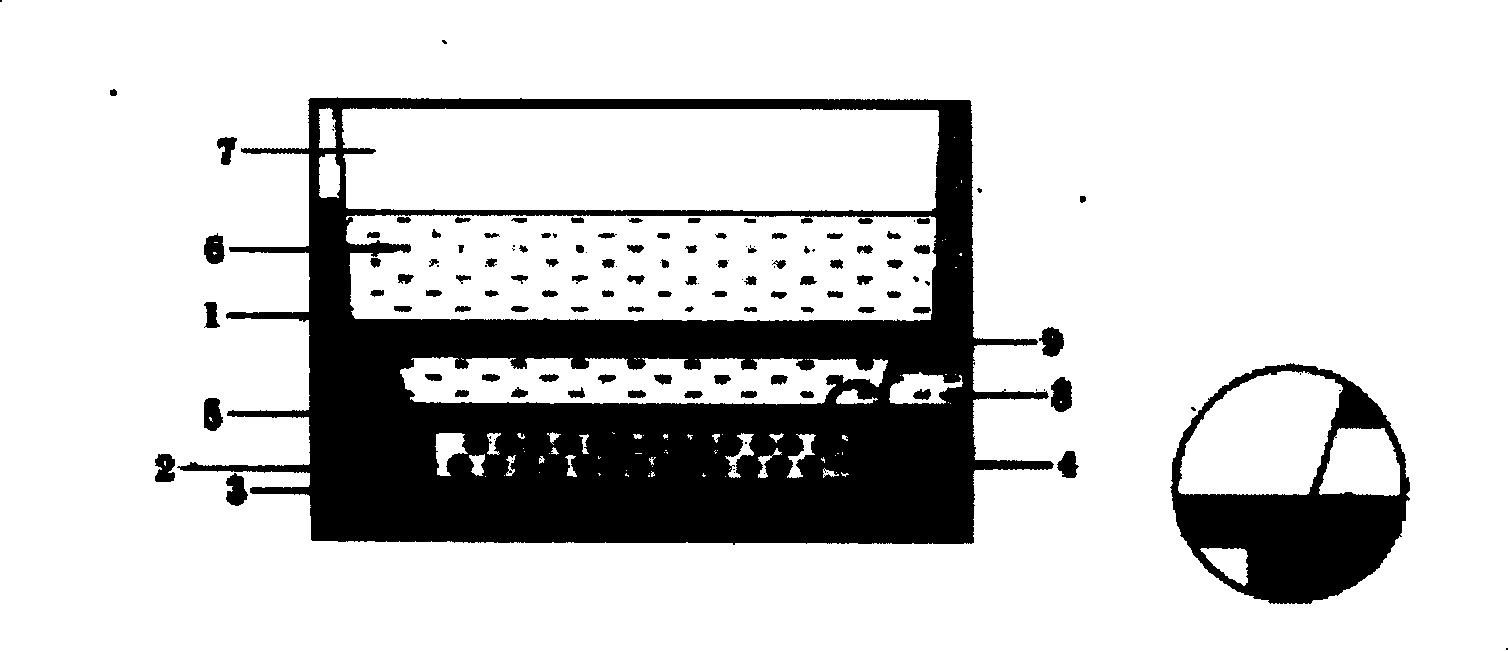

[0039] Such as figure 1 As shown, it is the first basic structure of the heating device at the bottom of the liquid metal container - the bottom electric heating filter box, the main body is a refractory material box 1, and the bottom of the box has a cavity 2, and the heating chamber 3 is embedded in the cavity to generate heat The body 4 is placed in the heating chamber, the heat conduction plate 5 is placed above the heating chamber, and the filter plate 9 is placed in the box above the heat conduction plate. The heating element preheats the filter plate in advance, and the aluminum melt 6 enters the box body through the aluminum melt inlet 7, passes through the filter plate to remove dross, and is discharged from the aluminum melt outlet 8.

Embodiment 2

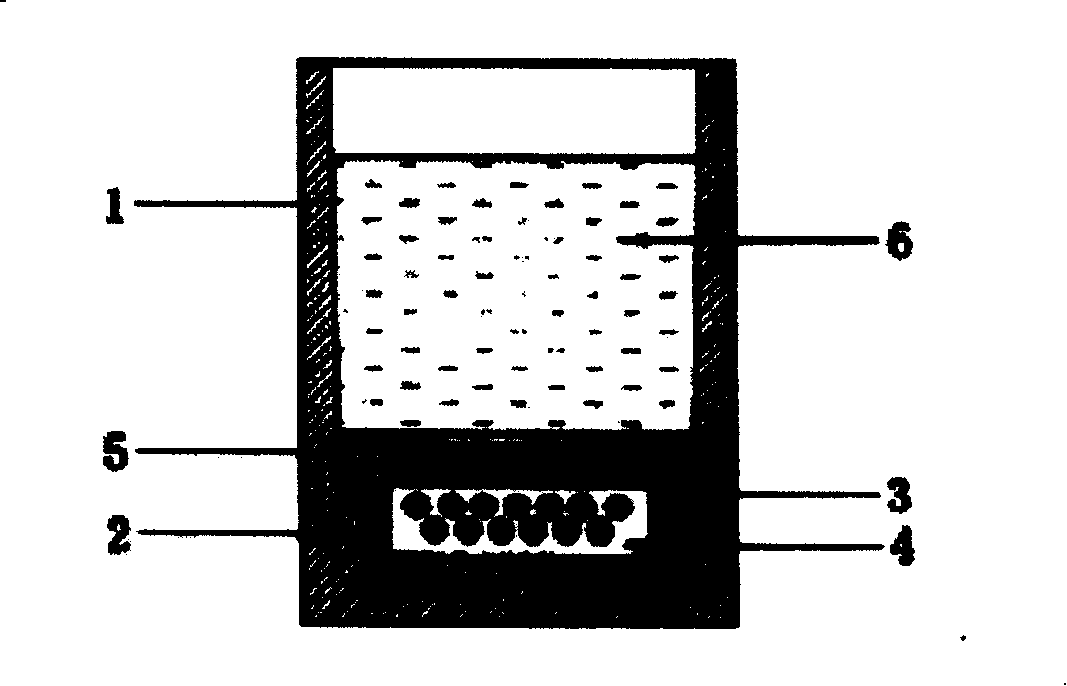

[0041] Such as figure 2 As shown, it is the second basic structure of the heating device at the bottom of the liquid metal container - launder heated at the bottom, smaller static furnace, holding furnace and various refining devices outside the furnace. The main body is a refractory material box 1 , The bottom of the box has a cavity 2, the heating chamber 3 is embedded in the cavity, the heating element 4 is placed in the heating chamber, and the heat conducting plate 5 is placed above the heating chamber.

Embodiment 3

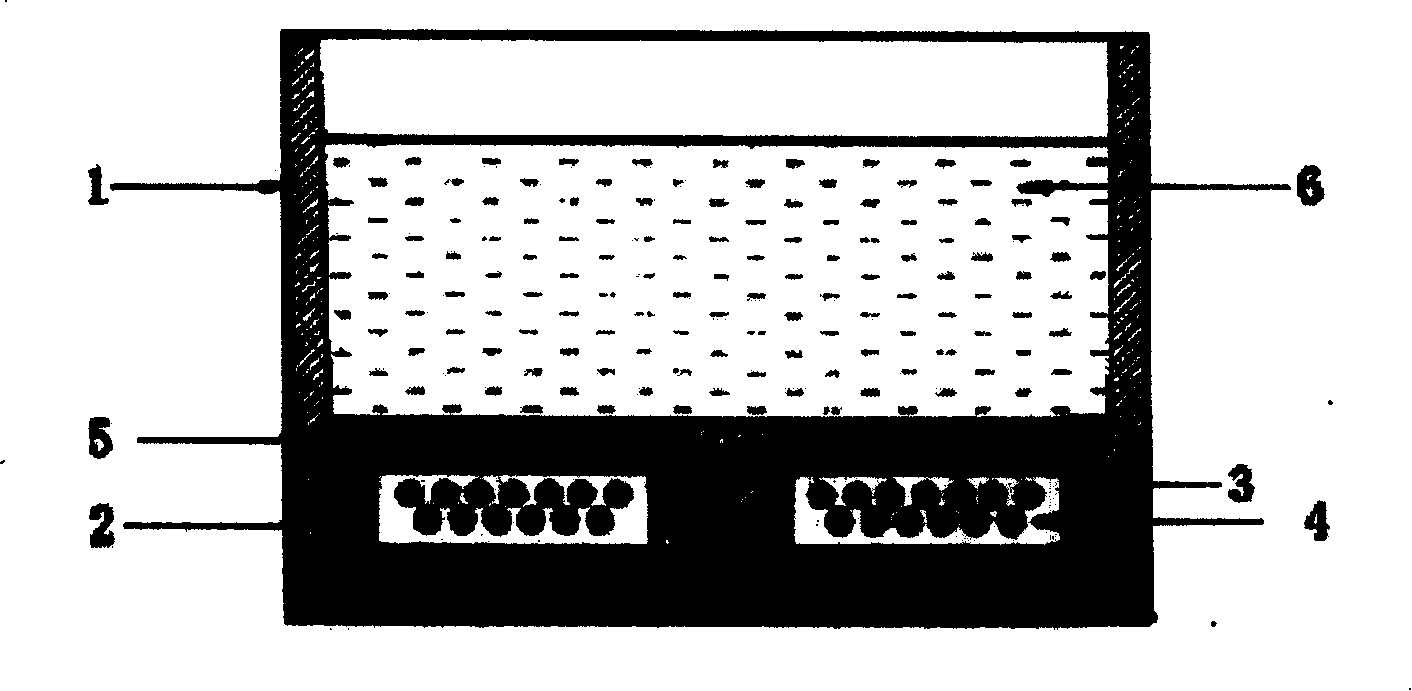

[0043] Such as image 3 As shown, it is the third basic structure of the heating device at the bottom of the liquid metal container - a larger static furnace, a holding furnace and a refining device outside the furnace. The main body is a refractory material box 1, and the bottom of the box has two The cavity 2 and the heating chamber 3 are embedded in the cavity, the heating element 4 is placed in the heating chamber, and the heat conducting plate 5 is placed above the heating chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com