Circulating water bath high-temperature micro etching visualization clamping model and use method thereof

A circulating water bath and water bath technology, applied in the direction of earthwork drilling, mining fluid, wellbore/well parts, etc., can solve the problems of experimental accuracy, small heating area, uneven heating, etc., to achieve uniform and stable heating, Easy to disassemble and assemble, and the effect of real ambient temperature on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation.

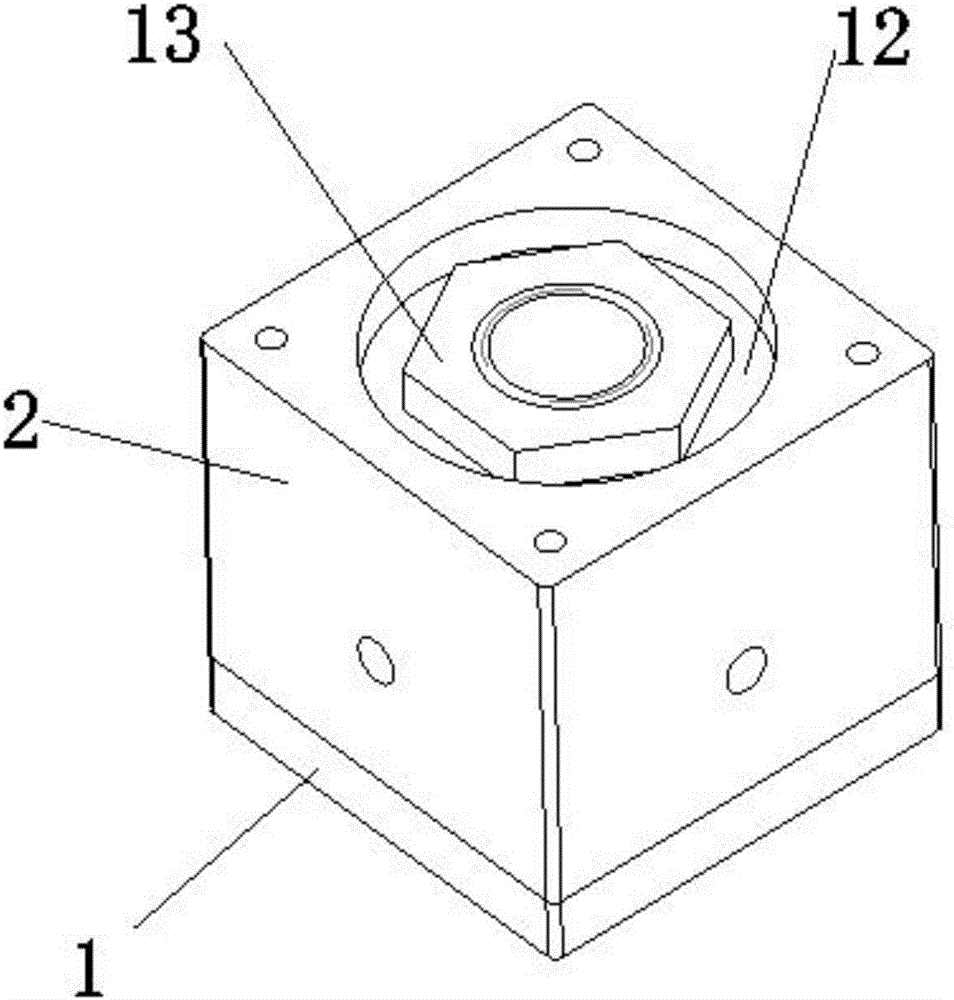

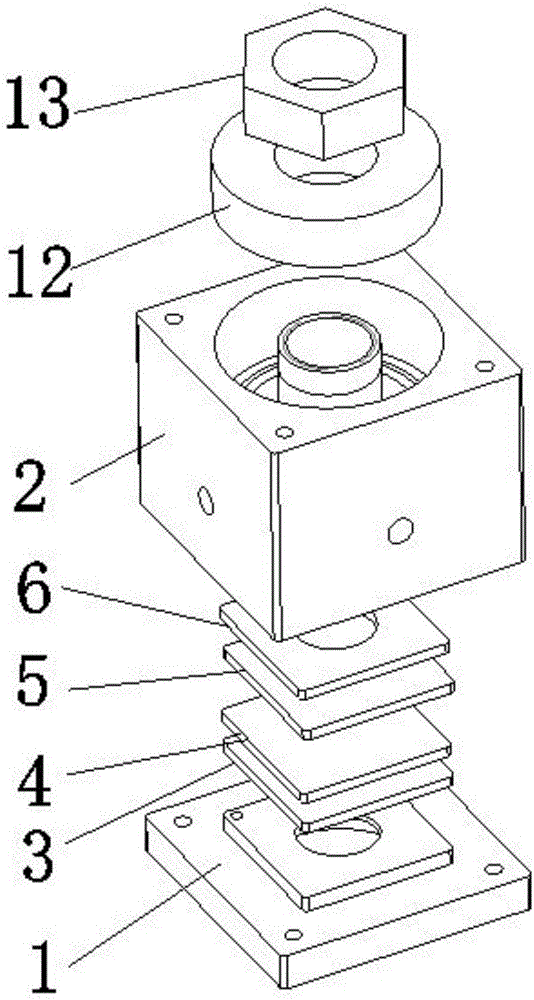

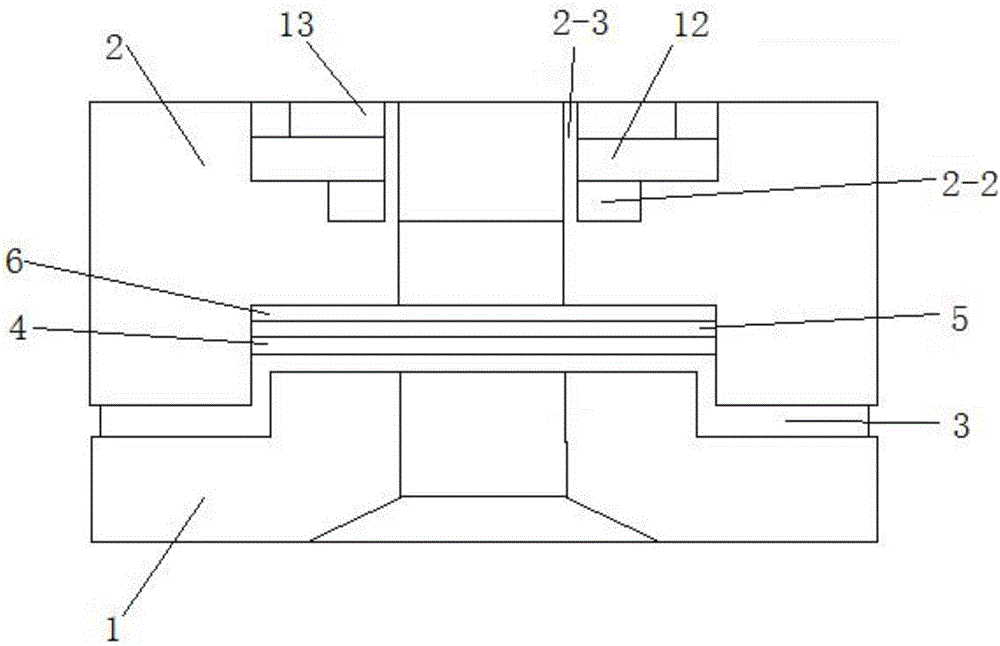

[0033] Such as Figure 1 ~ Figure 3 As shown, a high-temperature micro-etching visualization clamping model in a circulating water bath, including a focusing cover 1, a water bath seat 2, a water bath seat sealing film 6, an etching glass sheet 4, an observation glass sheet 5, a focusing cover sealing film 3, Bolts, glands 12, nuts 13; the water bath seat 2 is aligned with the condenser cover 1, connected by bolts, in the cavity formed between the condenser cover 1 and the water bath seat 2, the water baths are placed sequentially from bottom to top Seat sealing film 6, etching glass sheet 4, observation glass sheet 5, condenser cover sealing film 3; nut 13 installs the gland 12 under the water bath seat 2.

[0034] Such as Figure 8 ~ Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com