Film-drawing loading equipment for sandwiched film of automobile front windshield

A front windshield and diaphragm technology, which is applied in the field of film-drawing equipment, can solve problems such as the lack of automatic deviation correction function of the clamping transmission roller, fatigue of film-drawing operators, and hasty time to change parameters, etc., to achieve uniform and stable heating , Improve the quality of the film, and the effect of convenient and fast switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

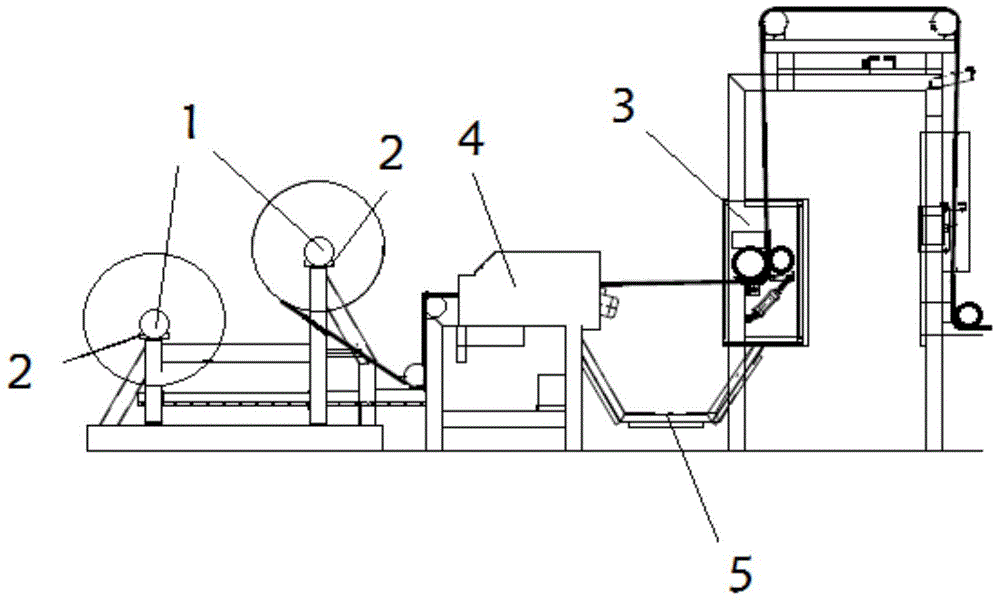

Image

Examples

Embodiment 2

[0048] The similarities between this embodiment and the first embodiment will not be described, and only the differences will be described.

[0049] The significant difference between this embodiment and Embodiment 1 is that in this embodiment, the film transmission driving device 3 is arranged on the upper film frame 1, and it automatically releases a roll of film when it is about to be used up. , to make the remaining film in the film roll drop into the film buffer tray 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com