Heating molding device for cement culvert pipe production and using method thereof

A technology of heating and shaping and cement, which is applied in the direction of ceramic forming machines and manufacturing tools, which can solve the problems of inconvenient production, slow process, and troublesome placing and exiting, and achieve the effects of stable and uniform heating, improved convenience, and improved shaping efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

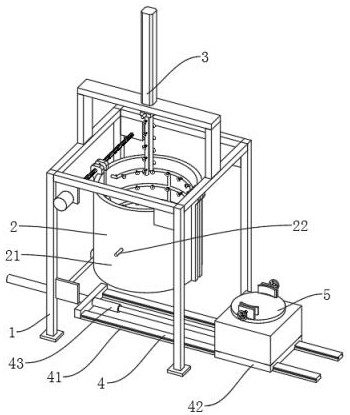

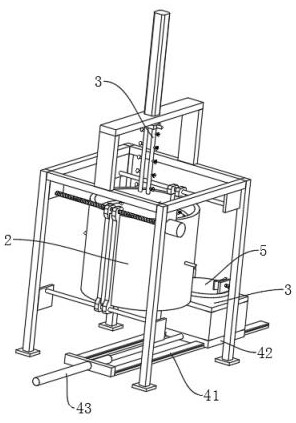

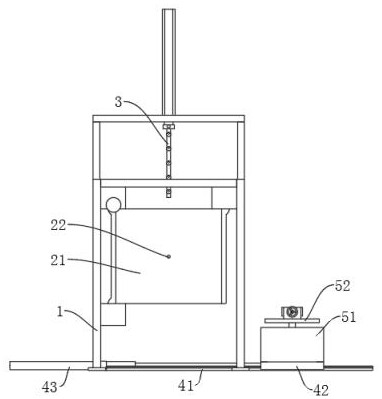

[0047] Such as Figure 1-Figure 7 As shown, a heating and shaping device for the production of cement culvert pipes includes a support frame 1 and an outer ring heating and shaping mechanism 2 arranged on the support frame 1. The center of the outer ring heating and shaping mechanism 2 is provided with an inner ring heating and shaping device. Mechanism 3, the inner ring heating and shaping mechanism 3 is set above the support frame 1, the lower side of the support frame 1 is provided with a moving mechanism 4, the upper end of the moving mechanism 4 is provided with a rotating support mechanism 5, the rotating supporting mechanism 5 is connected with the moving mechanism 4, and the outer ring The heating and setting mechanism 2 is connected with the support frame 1;

[0048] The outer ring heating and shaping mechanism 2 includes a symmetrically arranged outer casing 21, the outer casing 21 is pierced with a feed pipe 22, and the outlet end of the feeding pipe 22 is located o...

Embodiment 2

[0054] Such as Figure 1-Figure 6 , Figure 8 As shown, a heating and shaping device for the production of cement culvert pipes includes a support frame 1 and an outer ring heating and shaping mechanism 2 arranged on the support frame 1. The center of the outer ring heating and shaping mechanism 2 is provided with an inner ring heating and shaping device. Mechanism 3, the inner ring heating and shaping mechanism 3 is set above the support frame 1, the lower side of the support frame 1 is provided with a moving mechanism 4, the upper end of the moving mechanism 4 is provided with a rotating support mechanism 5, the rotating supporting mechanism 5 is connected with the moving mechanism 4, and the outer ring The heating and setting mechanism 2 is connected with the support frame 1;

[0055] The outer ring heating and shaping mechanism 2 includes a symmetrically arranged outer casing 21, the outer casing 21 is pierced with a feed pipe 22, and the outlet end of the feeding pipe 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com