Preparation process of high-temperature bubble-reducing double-rib double-color reinforced spiral corrugated pipe

A spiral corrugated pipe and a preparation process technology, applied in the field of corrugated pipes, can solve the problems that the tolerance accuracy of finished products is difficult to meet the standard, the production process of corrugated pipes is not easy to meet the standard, and the failure rate of corrugated pipes is high, so as to improve production quality, improve shaping efficiency, Damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

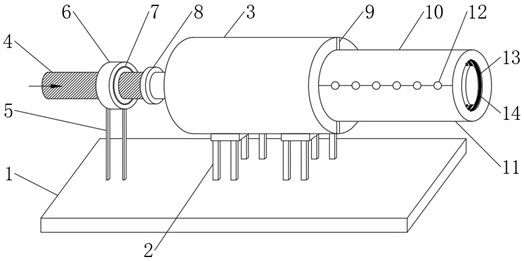

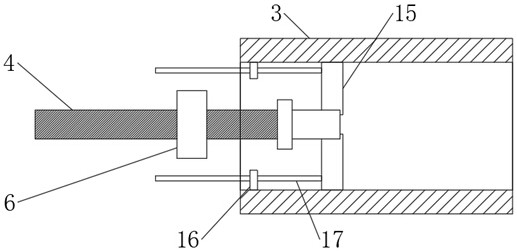

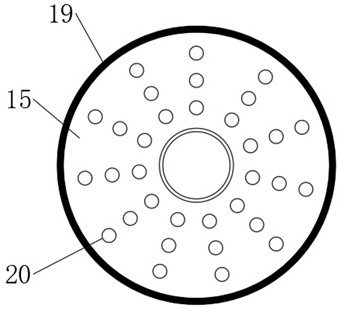

[0044] see Figure 1-5 , a preparation process of double-rib double-color reinforced spiral corrugated pipe with high temperature and foam reduction, comprising the following steps:

[0045] S1. Dry the wood powder with two-stage combined pulse air flow, and dry it in an environment of 120°C for 2 hours to make its moisture lower than 320mg / kg. After cooling to room temperature, mix it with a coupling agent and put it in a mixer, and heat it to After 75°C, rotate at a speed of 850RPM for 8 minutes to obtain compound A, add high-density polyethylene, elastomer, modified masterbatch, and color masterbatch and mix evenly to obtain compound B;

[0046] S2. Put the mixture A and mixture B in S1 into a mixer, add a defoamer and an antioxidant, and rotate at a speed of 350 RPM for 35 minutes under a high temperature environment to obtain a mixture C;

[0047] S3. Drying and plasticizing: put the mixed material C into the dryer and dry for 20 minutes, the drying temperature is 70-85°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com