Embroidery thread splicing and shaping equipment and method

An embroidery thread and thread-stitching technology, applied in textile and papermaking, spray/jet textile material processing, etc., can solve the problems of short storage life, inability to fix the shape of the embroidery thread, low efficiency, etc. Aesthetics, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

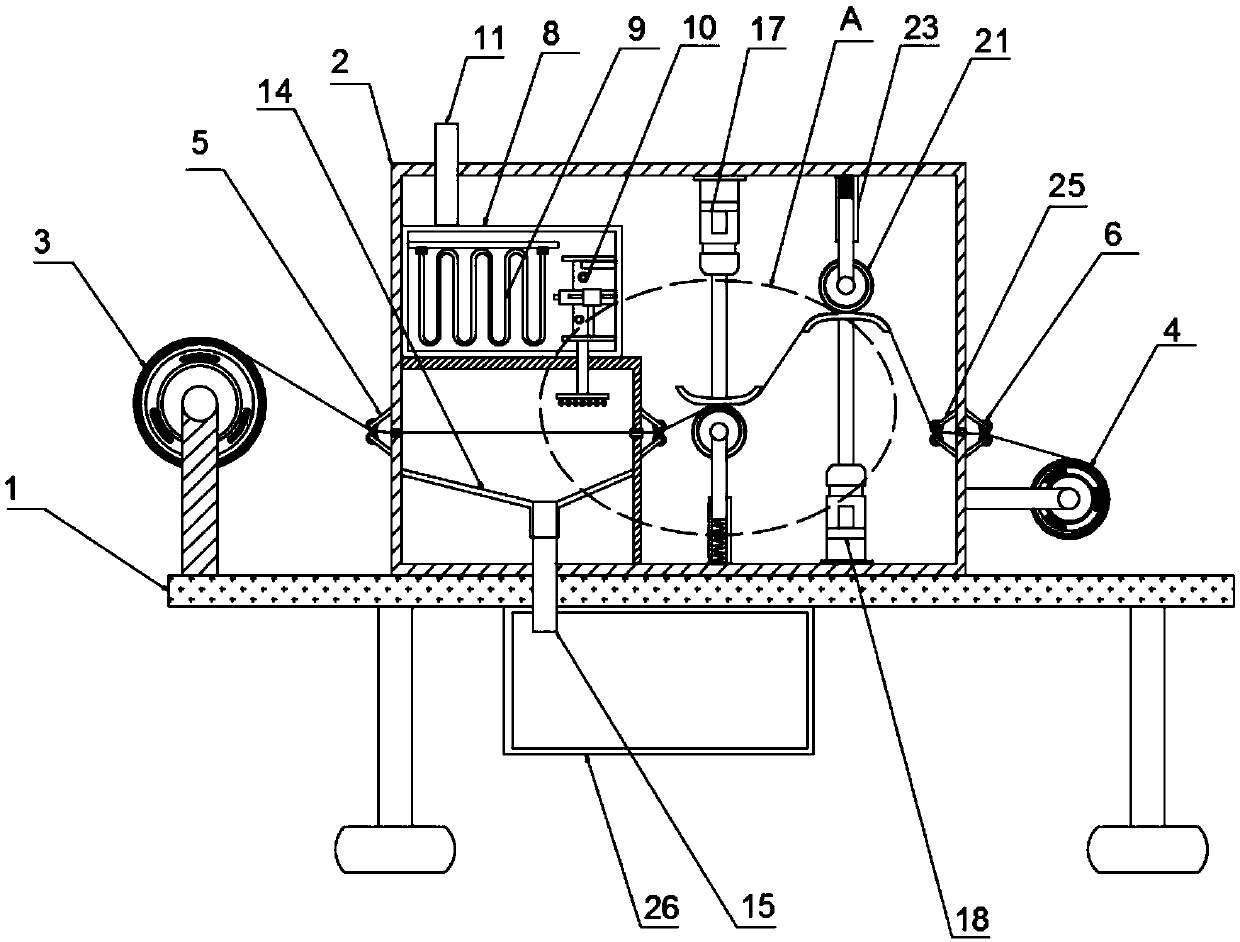

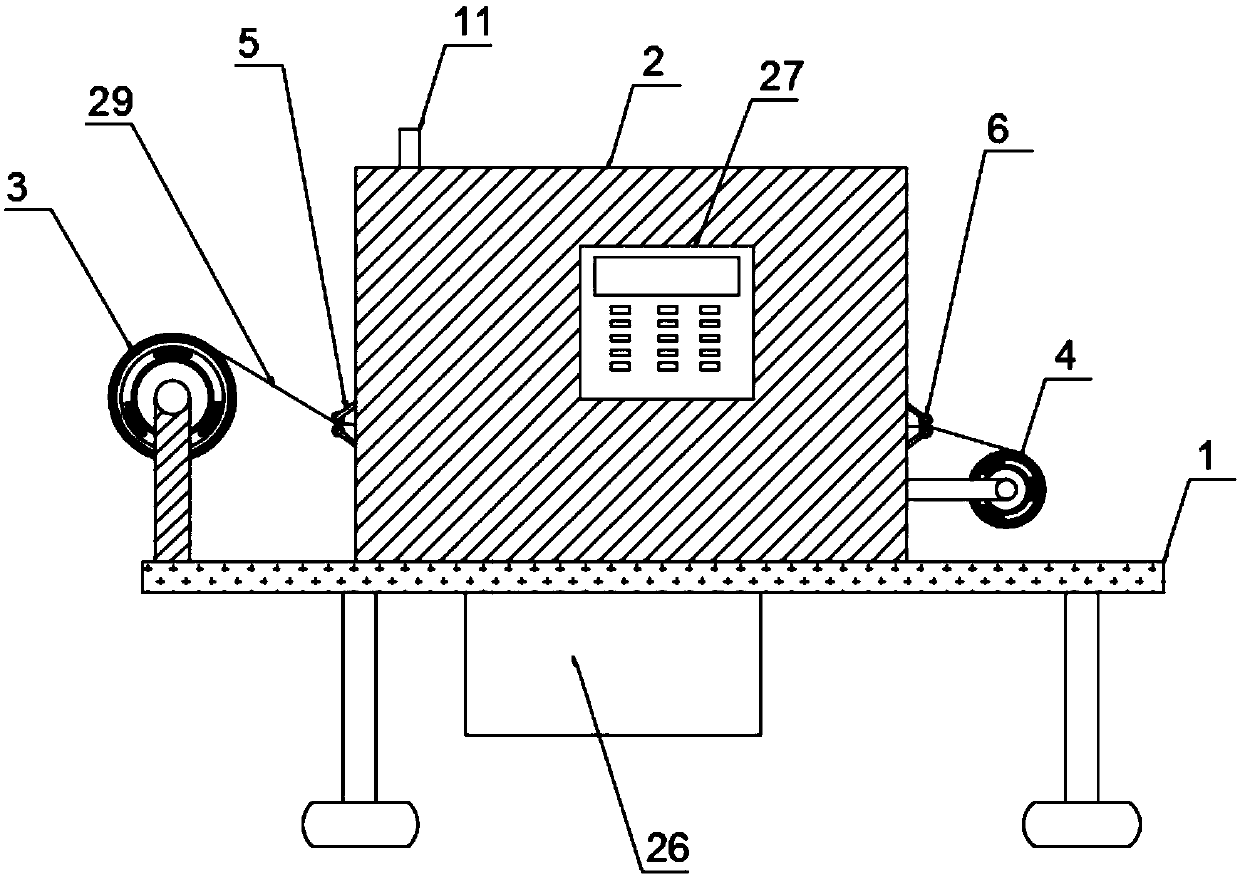

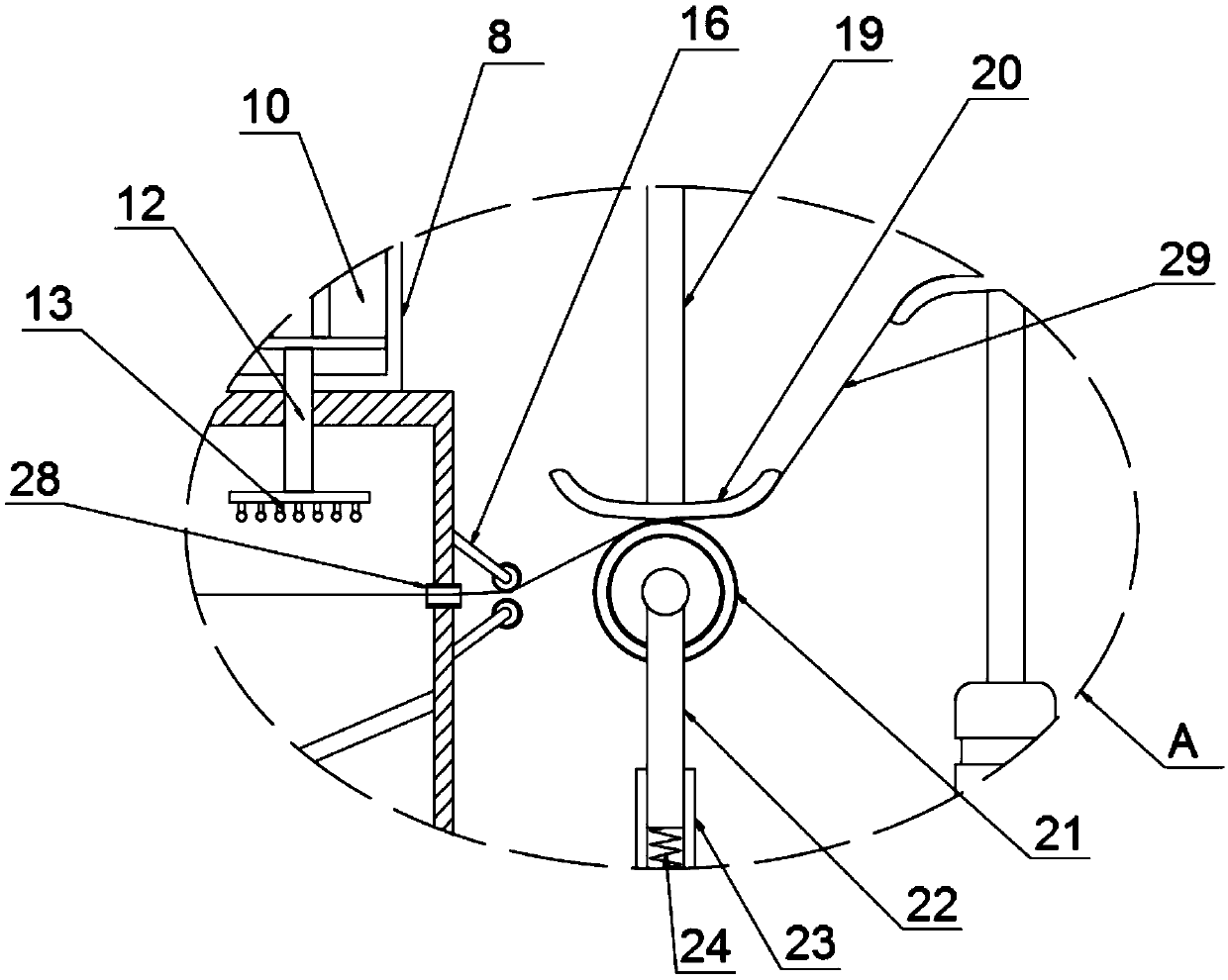

[0025] like Figure 1-3 The shown embroidery thread stitching and shaping equipment includes a workbench 1, a shaping box 2 is arranged on the top of the workbench 1, a winding roller 3 is arranged on one side of the shaping box 2, and a recovery stick is arranged on the other side 4. One side wall of the shaping box 2 is provided with a first adjusting roller 5, and the other side wall is provided with a second adjusting roller 6. The inside of the shaping box 2 is provided with a humidifying box 7, and the top of the humidifying box 7 is provided There is a hot water tank 8, the inner cavity of the hot water tank 8 is provided with a heating pipe 9, a pressure pump 10 is provided on one side of the heating pipe 9, a water inlet pipe 11 is provided at the top of the hot water tank 8 and an outlet pipe is provided at the bottom. Water pipe 12, the bottom end of the outlet pipe 12 is provided with a nozzle 13, the bottom of the nozzle 13 is provided with a drainage plate 14, th...

Embodiment 2

[0033] like Figure 1-3 Shown is a method for stitching and shaping embroidery threads, which specifically includes the following steps:

[0034] Step 1, use the water inlet pipe 11 to inject clear water into the hot water tank 8, send a control command to the relay through the PLC controller inside the control panel 27, control the heating pipe 9 to work, and heat the clear water in the hot water tank 8, and at the same time Send an on-off command to the relay at the input end of the pressure pump 10 to start the pressure pump 10, and the pressure pump 10 sprays the heated clear water in the hot water tank 8 on the inside of the humidification box 7 through the nozzle 13 at the bottom of the outlet pipe 12;

[0035] Step 2, the embroidery thread 29 wound on the winding roller 3 is transmitted between a plurality of thread holes 28, and the first regulating roller 5, the second regulating roller 6, the third regulating roller 16 and the fourth regulating roller 25 are to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com