Novel carpet yarn production process method and setting machine for superheated steam

A superheated steam, production process technology, applied in heating/cooling fabrics, liquid/gas/vapor yarn/filament processing, textile and papermaking, etc., can solve the problem of poor yarn softness and bulkiness, and insufficient adsorption permeability , poor lodging resistance and other problems, to achieve the effect of improving setting efficiency, improving twist stability and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

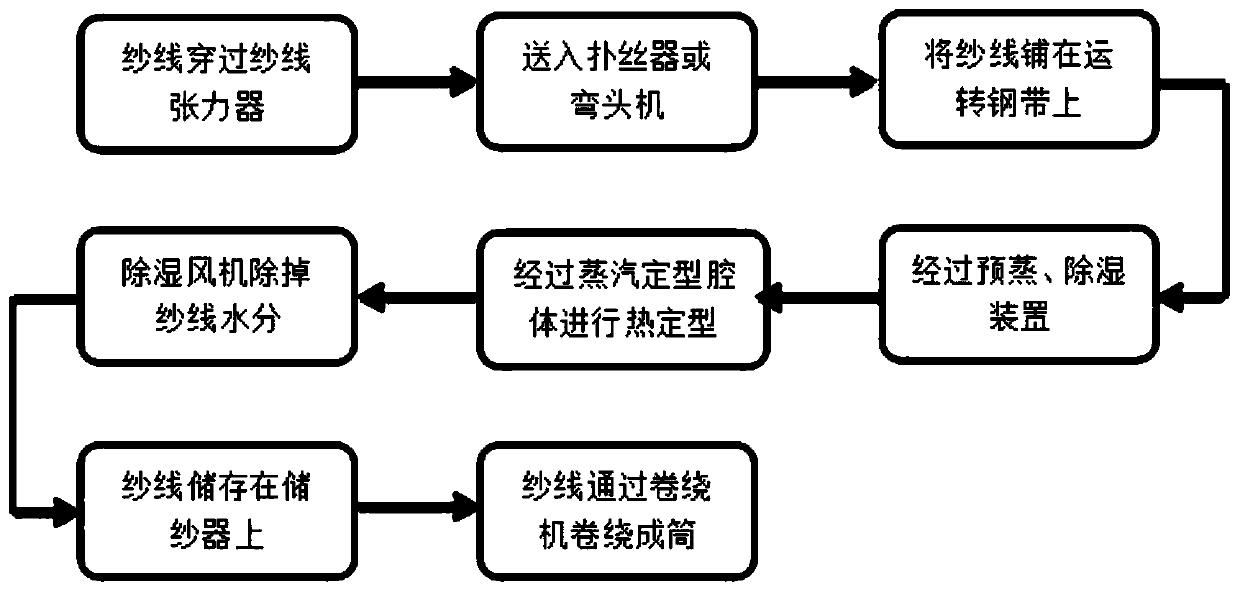

[0043] A kind of novel carpet yarn production method is characterized in that it comprises the following steps:

[0044] S1, the yarn passes through the yarn tensioner;

[0045] S2. Sending the yarn into the yarn puncher or elbow machine to lay the yarn on the running steel belt;

[0046] S3, after pre-steaming and dehumidification device;

[0047] S4, heat setting through the steam setting chamber, the heat setting temperature is 145 degrees.

[0048] S5, the dehumidification fan removes the moisture of the yarn;

[0049] S6. The yarn is stored on the yarn storage device, and the yarn is wound into a cylinder by a winding machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com