High-strength anti-static coated abrasive tool cloth base and treatment process thereof

A technology of coated abrasives and processing technology, which is applied in the direction of abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of not achieving the expected effect, uneven sand planting, and affecting the quality of electrostatic sand planting, so as to improve the cloth base Strength, improvement of antistatic property, effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

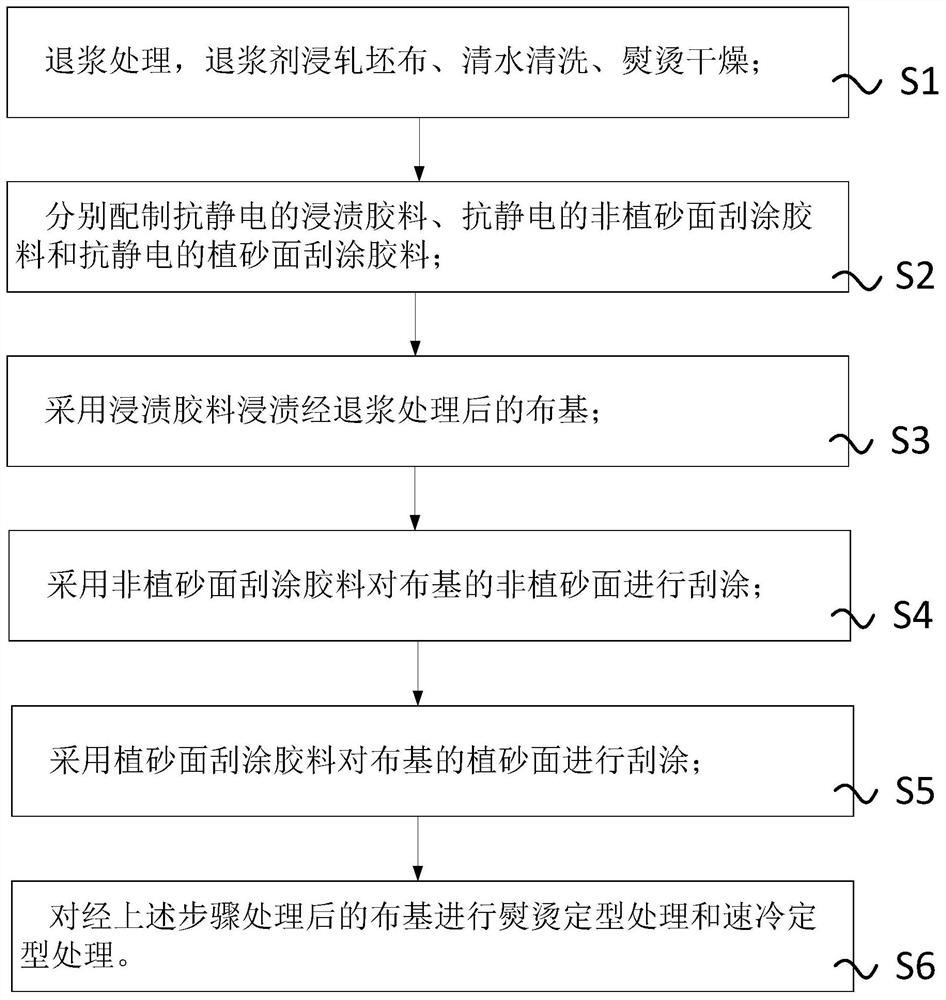

[0079] A treatment process for high-strength antistatic coated abrasive cloth, comprising the following steps:

[0080] (1) The gray cloth blended with carbon fiber and polyester fiber is used to prepare the cloth base. The gray cloth contains 70 parts by weight of polyester and 30 parts by weight of carbon fiber, and the yarn count is 12×10 (that is, 12 yarn counts in the radial direction and 10 yarn counts in the weft direction) ), density 102×42 (that is, radial density 102, weft density 42), unit weight 330g / m 2 ;

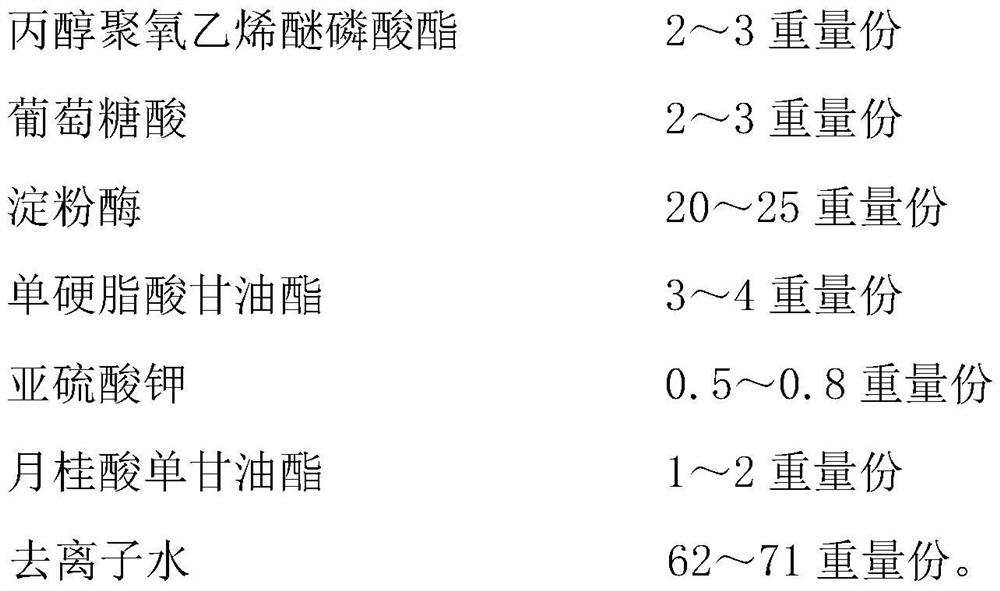

[0081] (2) prepare desizing agent;

[0082] (3) Padding the gray cloth with a desizing agent, desizing treatment of washing with water at 50°C and ironing and drying at 130°C;

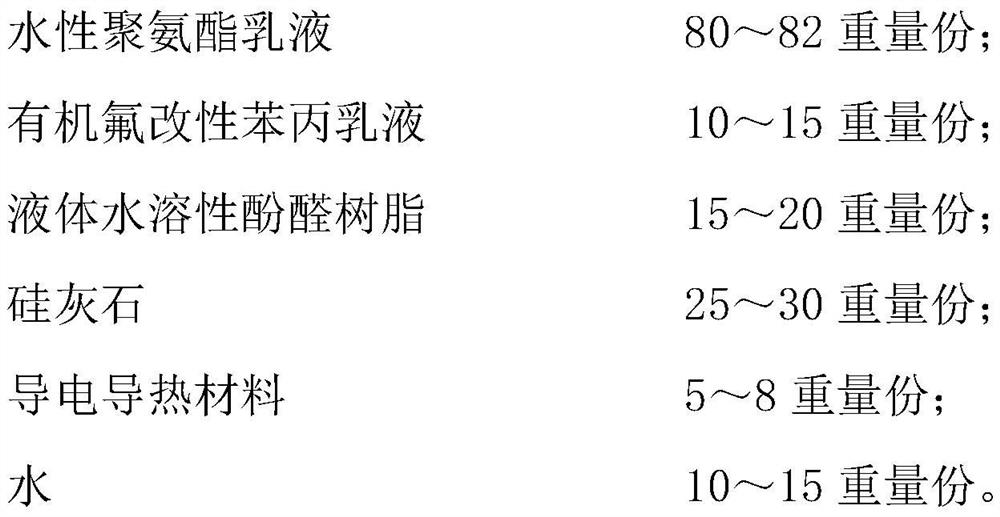

[0083] (4) Antistatic dipping sizing material, antistatic non-sanding surface scraping sizing material and antistatic sanding surface squeegee coating sizing material were prepared respectively;

[0084] (5) Use impregnation rubber to impregnate the cloth base after desizing treatmen...

Embodiment 2

[0093] A treatment process for high-strength antistatic coated abrasive cloth, comprising the following steps:

[0094] (1) Gray fabric blended with carbon fiber and polyester fiber is used to prepare the cloth base. The gray fabric contains 80 parts by weight of polyester and 20 parts by weight of carbon fiber, with a yarn count of 12×10, a density of 102×42, and a unit weight of 330g / m 2 ;

[0095] (2) prepare desizing agent;

[0096] (3) Padding the gray cloth with a desizing agent, desizing treatment of washing with water at 50°C and ironing and drying at 130°C;

[0097] (4) Antistatic dipping sizing material, antistatic non-sanding surface scraping sizing material and antistatic sanding surface squeegee coating sizing material were prepared respectively;

[0098] (5) Use impregnation rubber to impregnate the cloth base after desizing treatment, and control the impregnation coating amount to 180g / m 2 , after dipping, the oven was clamped and dried for 3 minutes, and the...

Embodiment 3

[0107] (1) Gray fabric blended with carbon fiber and polyester fiber is used to prepare the cloth base. The gray fabric contains 75 parts by weight of polyester and 25 parts by weight of carbon fiber, with a yarn count of 12×10, a density of 102×42, and a unit weight of 330g / m 2 ;

[0108] (2) prepare desizing agent;

[0109] (3) Padding the gray cloth with a desizing agent, desizing treatment of washing with water at 50°C and ironing and drying at 130°C;

[0110] (4) Antistatic dipping sizing material, antistatic non-sanding surface scraping sizing material and antistatic sanding surface squeegee coating sizing material were prepared respectively;

[0111] (5) Antistatic dipping rubber is used, and the dipping coating amount is controlled to 175g / m 2 After impregnation, the oven was clamped and dried for 2.5 minutes, and the drying temperature was controlled at 120°C;

[0112] (6) Scrape the non-sand-planted surface of the cloth base with anti-static scraping glue on the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com