Foil shaping device

A technology of shaping device and foil guide strip, which is applied in the fields of capacitor manufacturing, electrical components, capacitors, etc., can solve the problems of unguaranteed quality, low efficiency and high labor intensity in shaping processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

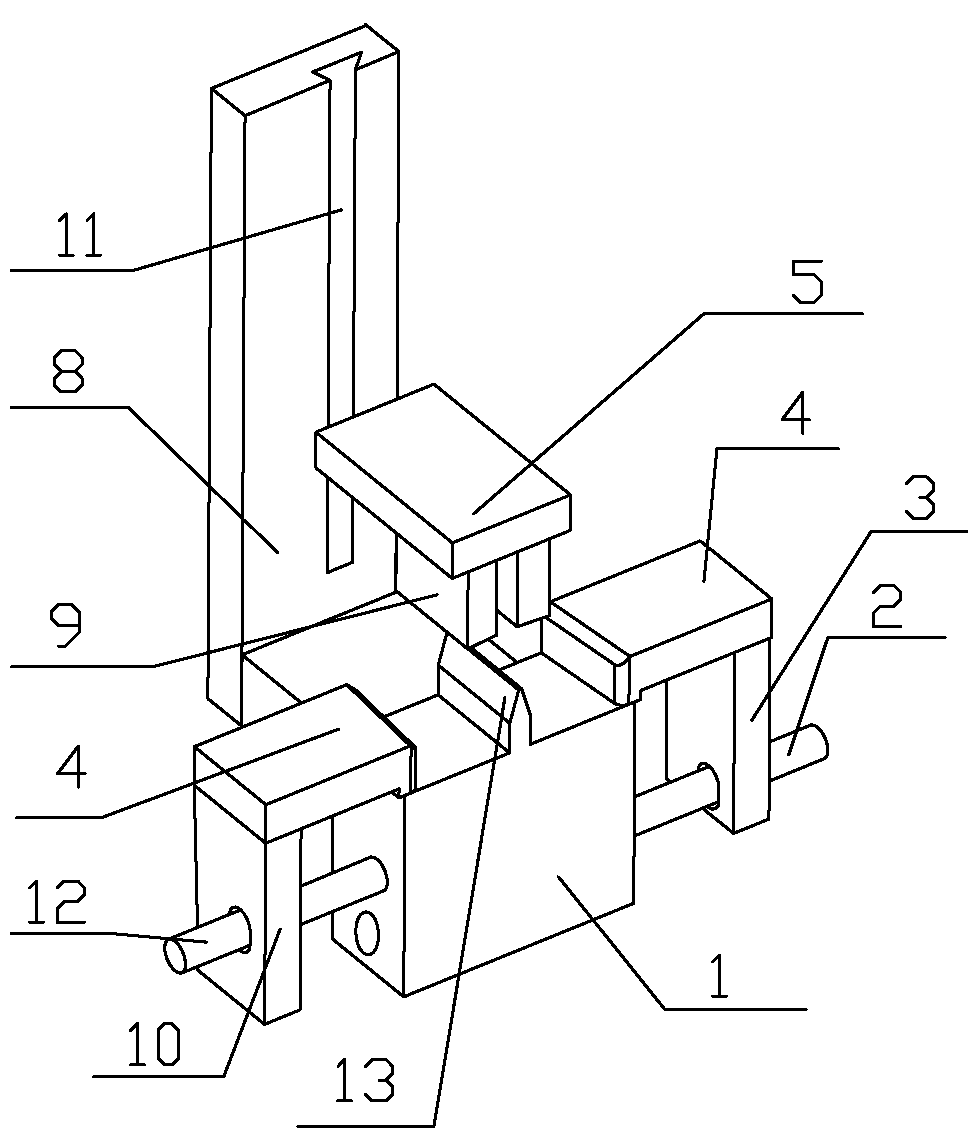

[0040] Such as figure 1As shown, the guide chaff shaping device includes a correcting bottom mold 1, an upper correcting mold arranged on the top of the correcting bottom mold 1, two horizontally correcting flat molds and a vertically arranged fixing plate 8; The middle part of the end face is provided with a protruding elongation direction as a bump 13 in the front and rear direction, and the correction bottom mold 1 is fixed on the lower end of the front side of the fixed plate 8; the upper correction mold includes a fixed block 5 and two correction blocks 9, The correction block 9 is fixed on the lower end surface of the fixed block 5 in parallel, and there is a channel between the two correction blocks 9, the elongation direction of the channel is the front and rear direction and the channel is connected with the bump 13 on the upper end of the correction bottom mold 1 In cooperation, the rear end of the fixed block 5 is provided with a boss (not shown in the figure), and...

Embodiment 2

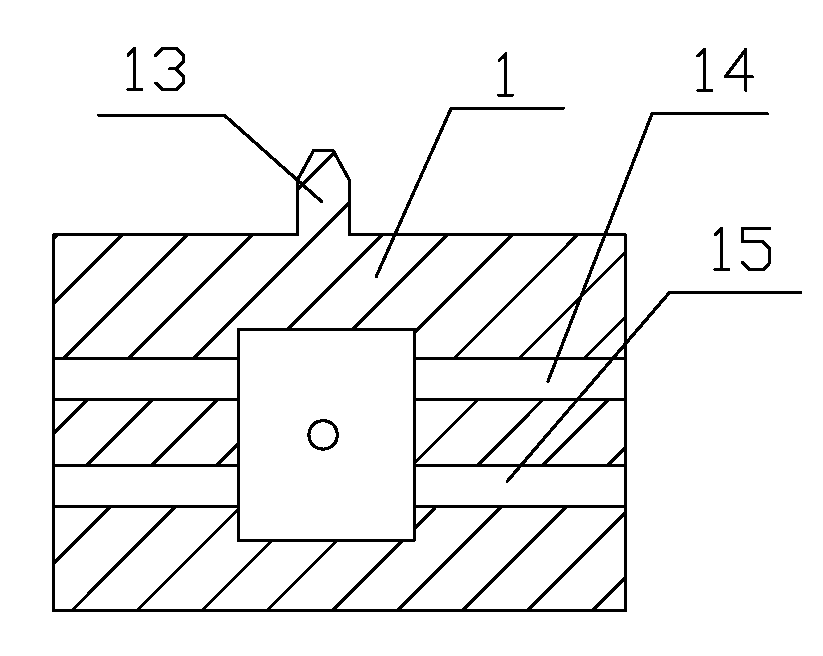

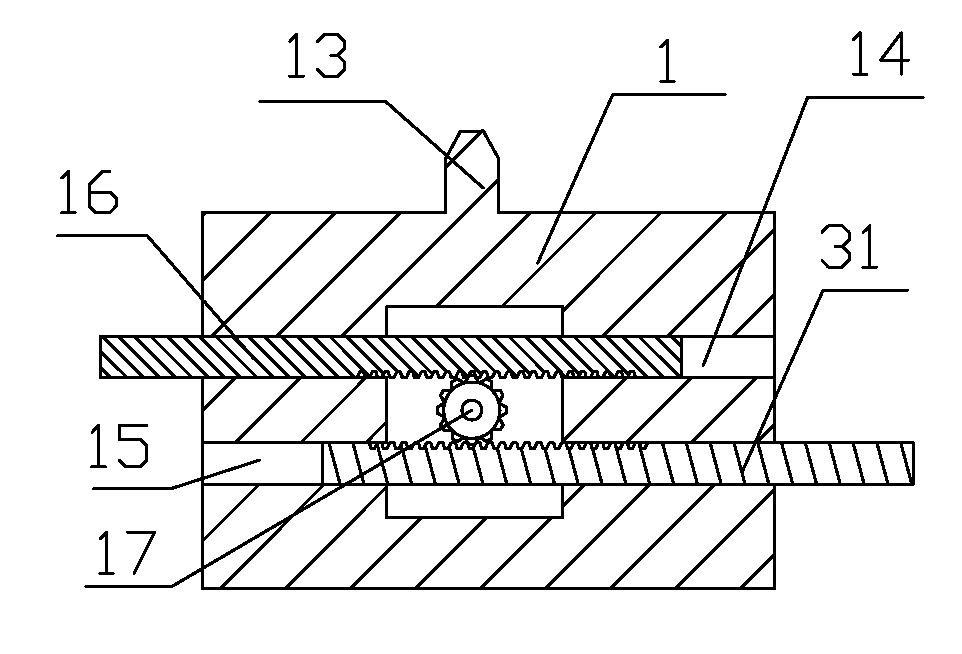

[0046] Such as figure 2 , 3 As shown, the structure of the guide chaff shaping device is basically the same as that of Embodiment 1, the difference is that: the middle part of the rear side of the corrected bottom mold 1 has an installation groove, and the left guide post 12 and the right guide post 2 are up and down. Setting, the lower end face of left guide post 12 is provided with lower rack, the upper end face of right guide post 2 is provided with upper rack, is provided with gear 17 in the mounting groove, and gear 17 meshes with lower rack, upper rack respectively.

[0047] The left guide post 12 and the right guide post 2 are meshed with the gear 17 respectively, so the movement of the left guide post 12 and the right guide post 2 is synchronized, and only one of the left guide post 12 or the right guide post 2 needs to be driven to move to drive the two. A synchronous movement can save the transmission device, simplify the device and reduce the cost.

Embodiment 3

[0049] Such as Figure 4 As shown, the structure of the guide chaff shaping device is basically the same as that of Embodiment 2, the difference is that: the upper end of the fixing plate 8 is fixed with a U-shaped block 18, and a guide is formed between the two sides of the U-shaped block 18. Groove 11; the boss is nested in the guide groove 11.

[0050] The U-shaped block 18 is used to form the guide groove 11, and the procedure of processing the guide groove 11 on the fixing plate 8 is omitted, which is simple, convenient and practical.

[0051] Further, the front side of the U-shaped block 18 is provided with a cover plate 6, and the boss extends upwards to form a slider 7, the upper end of the slider 7 stretches out from the U-shaped block 18, and the lower end of the slider 7 is connected to the upper correction mold. The rear end of the fixed block 5 is connected.

[0052] The cover plate 6 cooperates with the U-shaped block 18, so that the slider 7 can only move up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com