Method for setting speed of setting machine in dry cloth heat setting

A setting method, heating and shaping technology, applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of energy waste, energy waste, unfavorable cloth quality, etc., and achieve the effect of reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

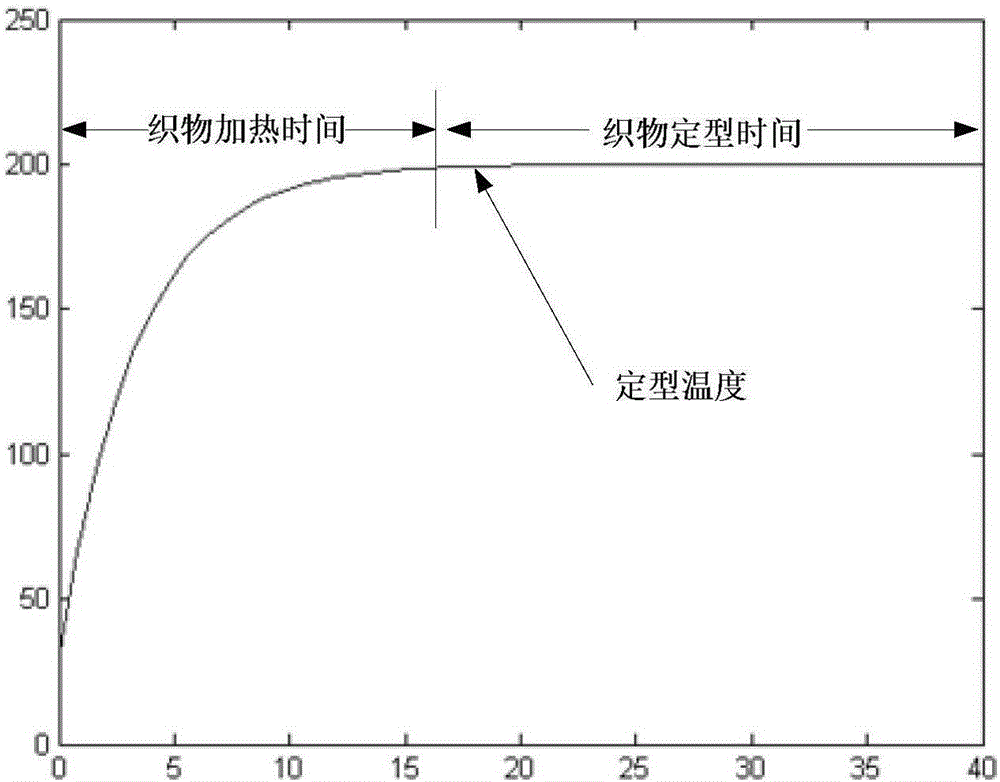

[0049] The fabric setting process is generally given when textile companies produce fabrics. The main indicators in the setting process parameters: setting temperature and setting time will give reference values. It is worth noting that the setting temperature and setting time here refer to figure 1 The part depicted in, figure 1 The middle abscissa is time (s), and the ordinate is temperature (°C). Therefore, the actual time to enter the setting machine is longer than the setting time described above. The process requirement is to ensure the duration after reaching the setting temperature is the setting time, so the total time of the cloth in the setting machine should be:

[0050] Total time = fabric heating time + fabric setting time;

[0051] In the actual setting, the engineers cannot estimate the heating time of the fabric well. In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com