Anti-deformation device for warp knitted fabric after forming

A deformation device and warp-knitted fabric technology, which is applied in the field of knitted fabrics, can solve the problems of easy deformation, straight-line fixation of knitted fabrics, and low shaping efficiency of warp-knitted fabrics, and achieve the effects of flexible adjustment and improved shaping efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

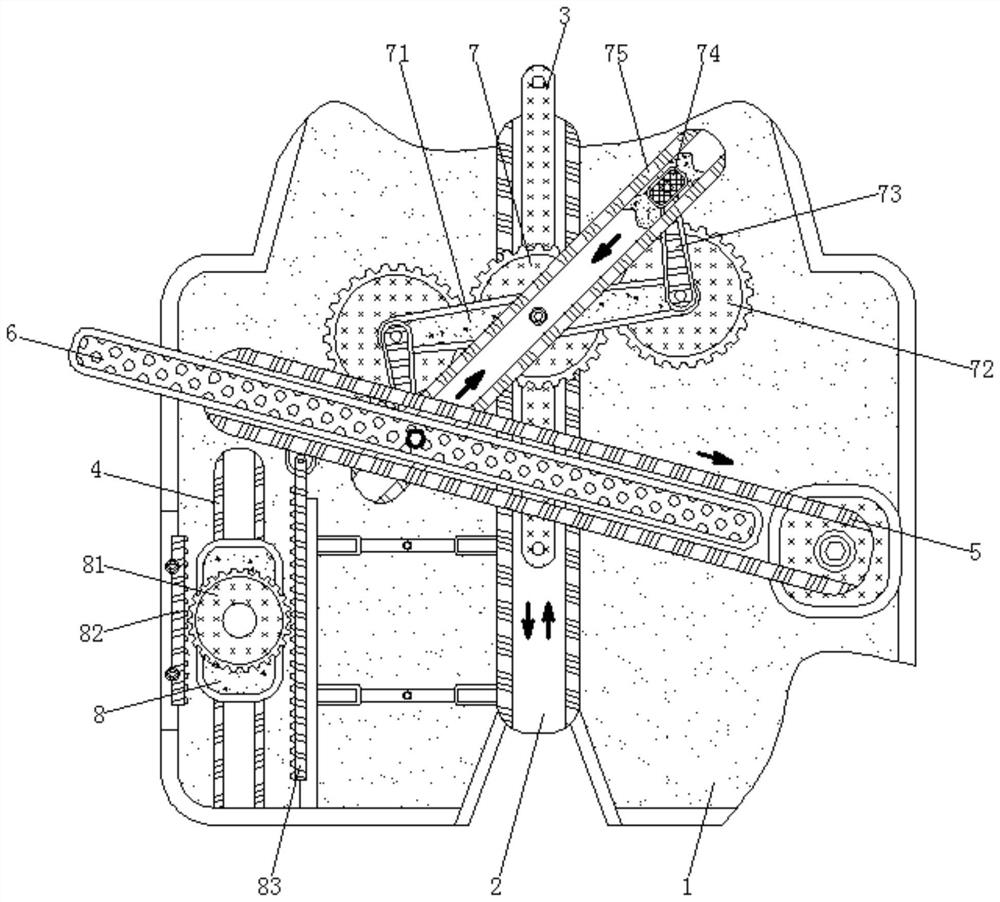

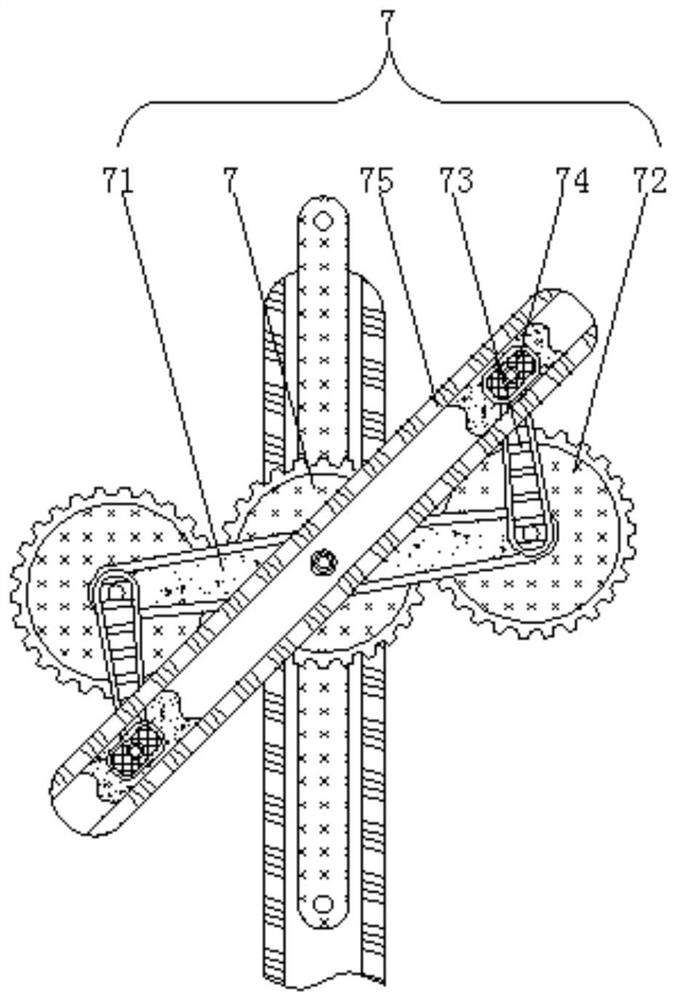

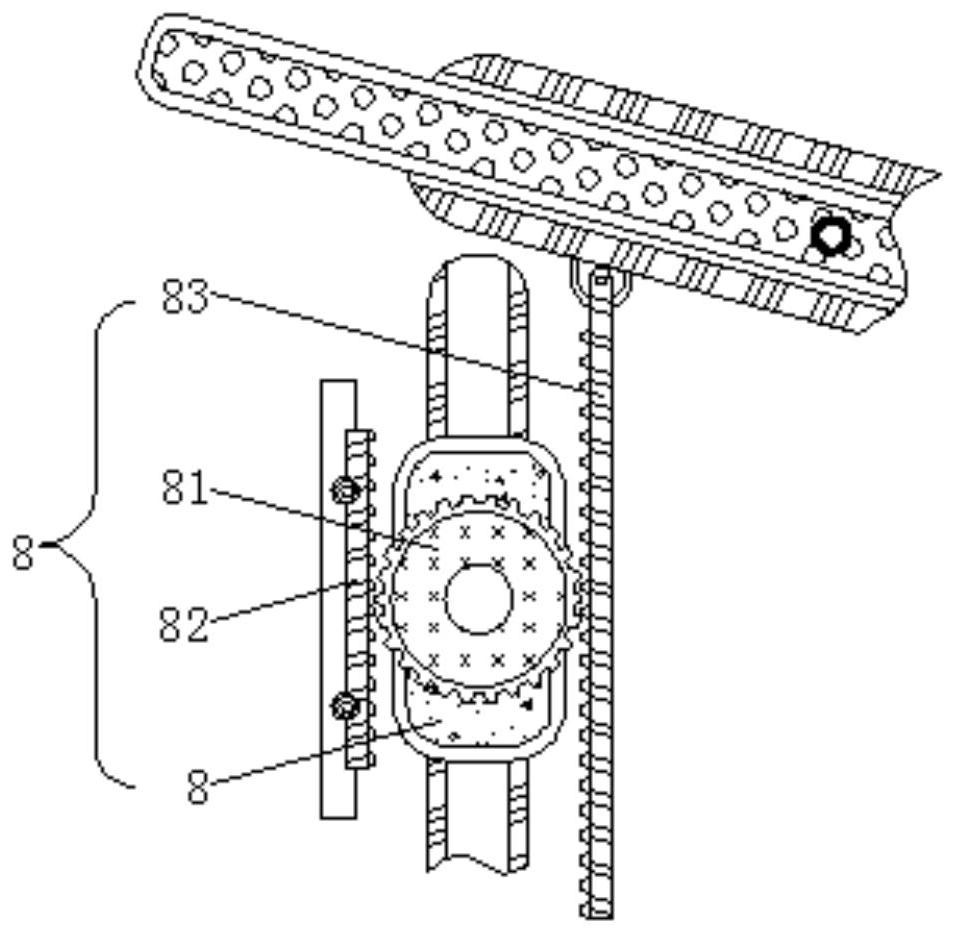

[0026] An anti-deformation device after forming warp knitted fabrics, comprising a driving gear mechanism 7, the driving gear mechanism 7 is rotatably connected to the surface of the driving guide rod 3, two pinion gear mechanisms 72 are provided, and they are respectively rotatably connected to two ends of the connecting rod 71. end, and these two secondary gear mechanisms 72 are meshed with the drive gear mechanism 7, and the front and back sides of the double-sided guide rail 75 are provided with a chute, and the slide block 74 is slidably connected to the back side of the double-sided guide rail 75.

[0027] The shaft center of the drive gear mechanism 7 is rotatably connected with a connecting rod 71, the drive guide rod 3 is arranged at the back axis of the drive gear mechanism 7, the connecting rod 71 is arranged at the front shaft center of the drive gear mechanism 7, and the double-sided guide rail 75 is arranged on the front axle center place of connecting rod 71, and...

Embodiment 2

[0032] An anti-deformation device after forming warp knitted fabrics, comprising a driving gear mechanism 7, the driving gear mechanism 7 is rotatably connected to the surface of the driving guide rod 3, two pinion gear mechanisms 72 are provided, and they are respectively rotatably connected to two ends of the connecting rod 71. end, and these two secondary gear mechanisms 72 are meshed with the drive gear mechanism 7, and the front and back sides of the double-sided guide rail 75 are provided with a chute, and the slide block 74 is slidably connected to the back side of the double-sided guide rail 75.

[0033] The shaft center of the drive gear mechanism 7 is rotatably connected with a connecting rod 71, the drive guide rod 3 is arranged at the back axis of the drive gear mechanism 7, the connecting rod 71 is arranged at the front shaft center of the drive gear mechanism 7, and the double-sided guide rail 75 is arranged on the front axle center place of connecting rod 71, and...

Embodiment 3

[0037] An anti-deformation device after forming warp knitted fabrics, comprising a driving gear mechanism 7, the driving gear mechanism 7 is rotatably connected to the surface of the driving guide rod 3, two pinion gear mechanisms 72 are provided, and they are respectively rotatably connected to two ends of the connecting rod 71. end, and these two secondary gear mechanisms 72 are meshed with the drive gear mechanism 7, and the front and back sides of the double-sided guide rail 75 are provided with a chute, and the slide block 74 is slidably connected to the back side of the double-sided guide rail 75.

[0038] The shaft center of the drive gear mechanism 7 is rotatably connected with a connecting rod 71, the drive guide rod 3 is arranged at the back axis of the drive gear mechanism 7, the connecting rod 71 is arranged at the front shaft center of the drive gear mechanism 7, and the double-sided guide rail 75 is arranged on the front axle center place of connecting rod 71, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com