System and method for full-automatic welding of standard joint of building hoist

A construction elevator and automatic welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high technical requirements for welders, slow production efficiency, toxic smoke and dust environment, etc., to improve labor intensity and work. The effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

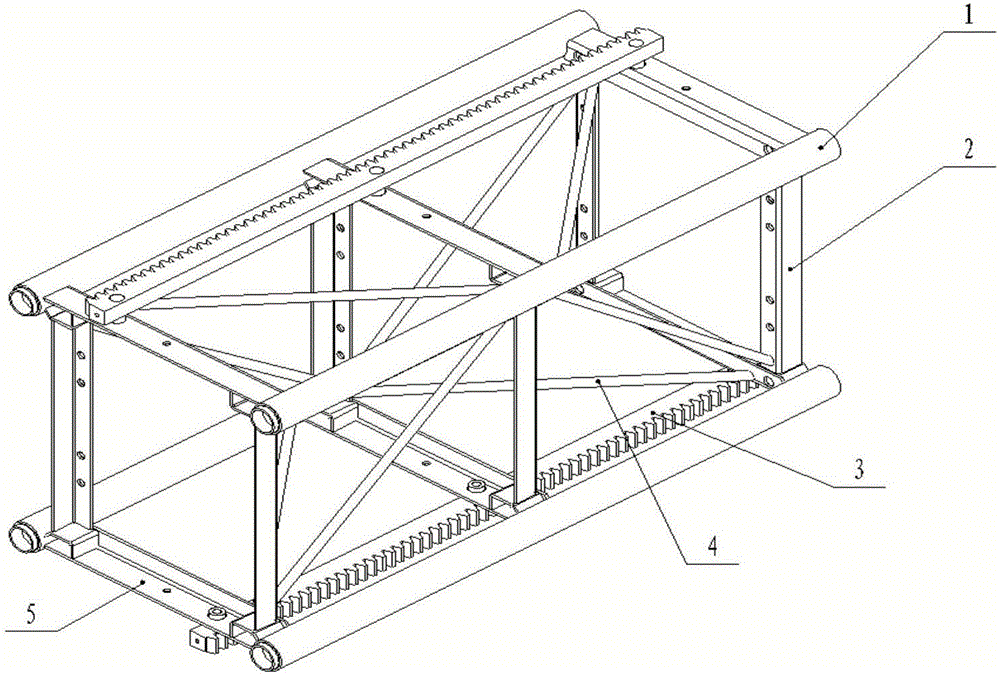

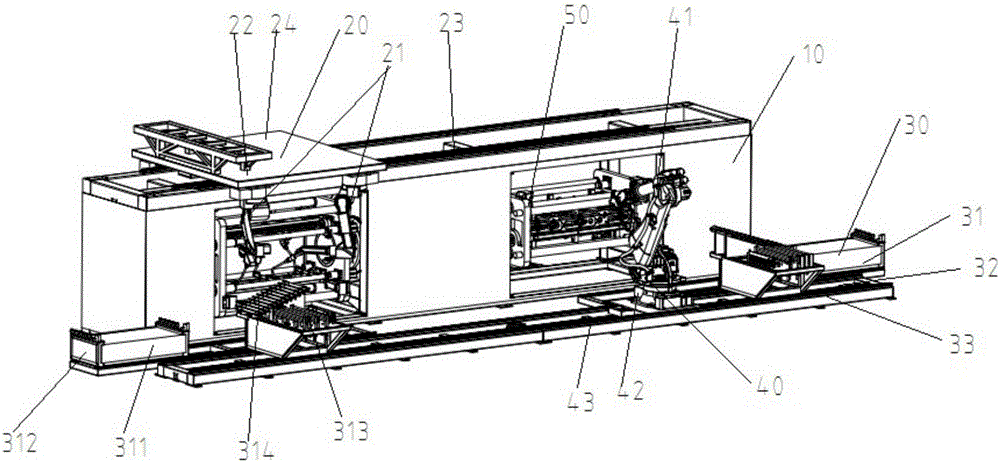

[0054] A system for fully automatic welding of standard sections of construction elevators, including a main body 10, a welding system 20, a feeding system 30, a handling system 40, a tooling system 50, and an unloading system 60;

[0055] The feeding system 3 includes a material platform 31, a material platform transfer platform 32 and a material platform walking track 33;

[0056] The transport system 4 includes a transport robot 41, a transport robot transfer platform 42 and a transport robot walking track 43;

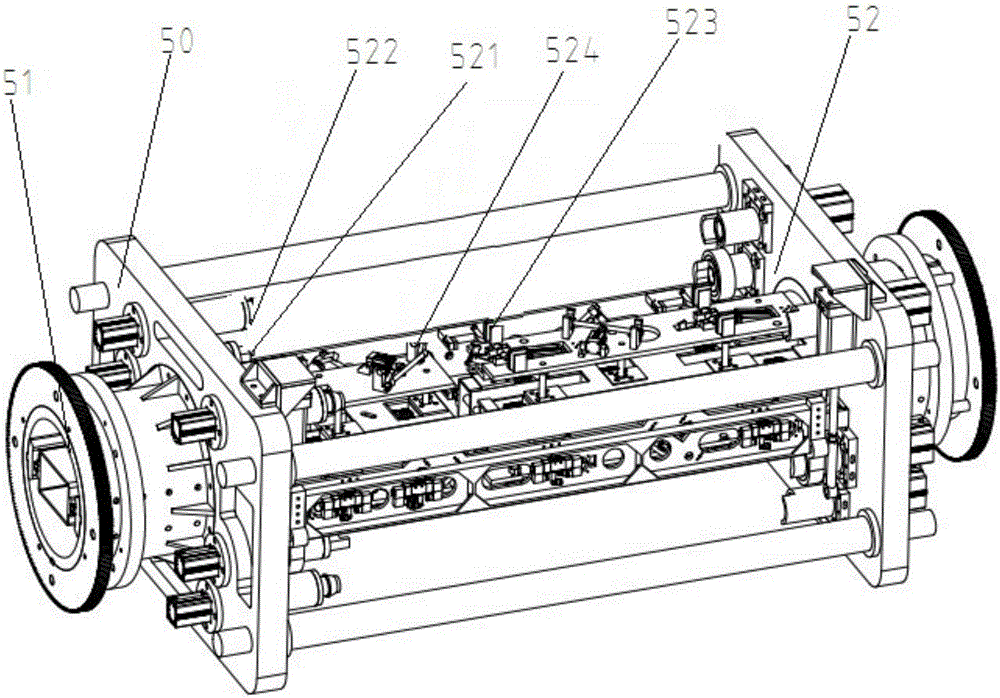

[0057] The tooling system 5 includes a rotary standard joint tooling 51 and a component clamping mechanism 52;

[0058] The welding system 2 includes a welding robot 21, a welding robot transfer platform 22 and a welding robot walking track 23;

[0059] Described unloading system 6 comprises unloading robot 61, unloading robot transfer platform 62 and unloading robot walking track 63;

[0060] The tooling system 5 is set inside the main body 1, the welding system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com