Hot-aie perming-hair method and apparatus

A technology of hot air and equipment, applied in the field of perm, can solve the problems of low perm setting quality and efficiency, inability to further improve hot air temperature, working efficiency and setting quality, and low working temperature, so as to improve operation efficiency and setting quality, and improve the consumption environment The effect of improving and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

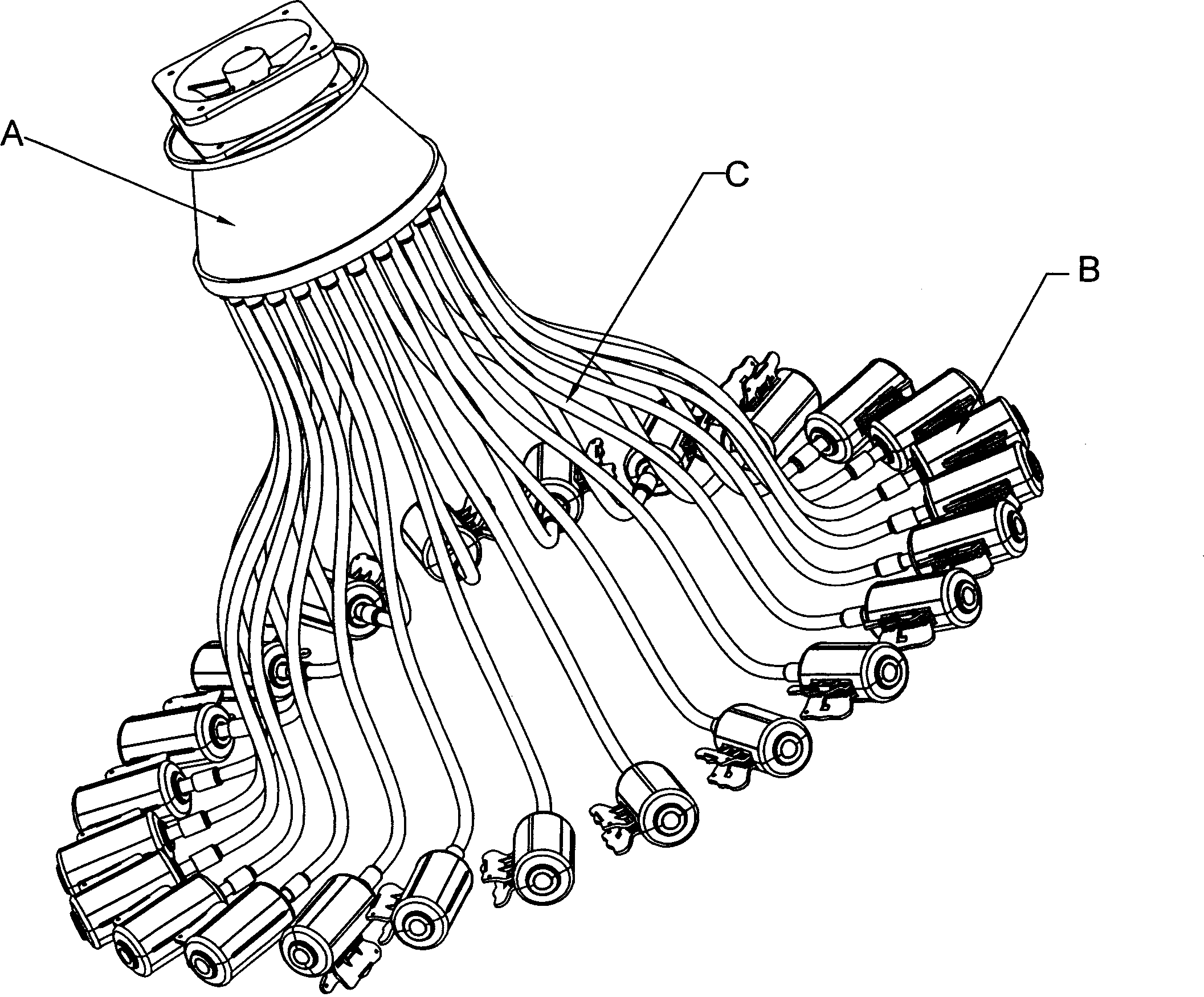

[0031] exist figure 1 The shown outline drawing of Embodiment 1 of the hot air perming device of the present invention includes a hot air blower A and 24 hair curlers B, and each hair curler B is connected to the air outlet port of the hot air blower A through a hot air duct C . The air outlet of the casing of the present invention has 24 air outlet ports, which can respectively provide hot air to each hair curler B through the hot air duct C respectively, so that the high-efficiency hot air perm can be equipped with stereotypes and three-dimensional perms become possible. At the same time, a plurality of air outlets are separated at the air outlet of the casing to ensure the uniformity of temperature among the curlers, the temperature difference between the curlers is small, and the quality of perm and curls is high.

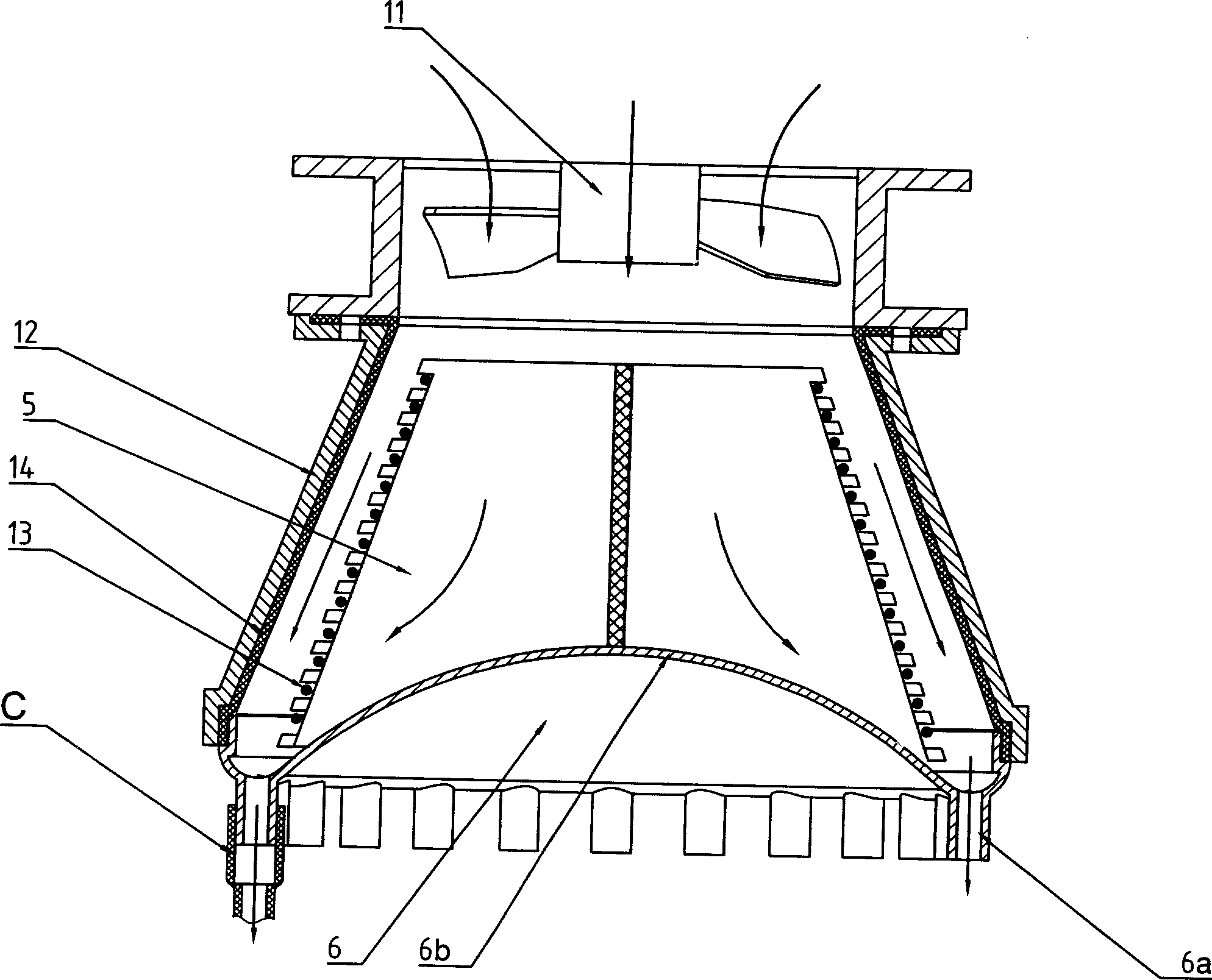

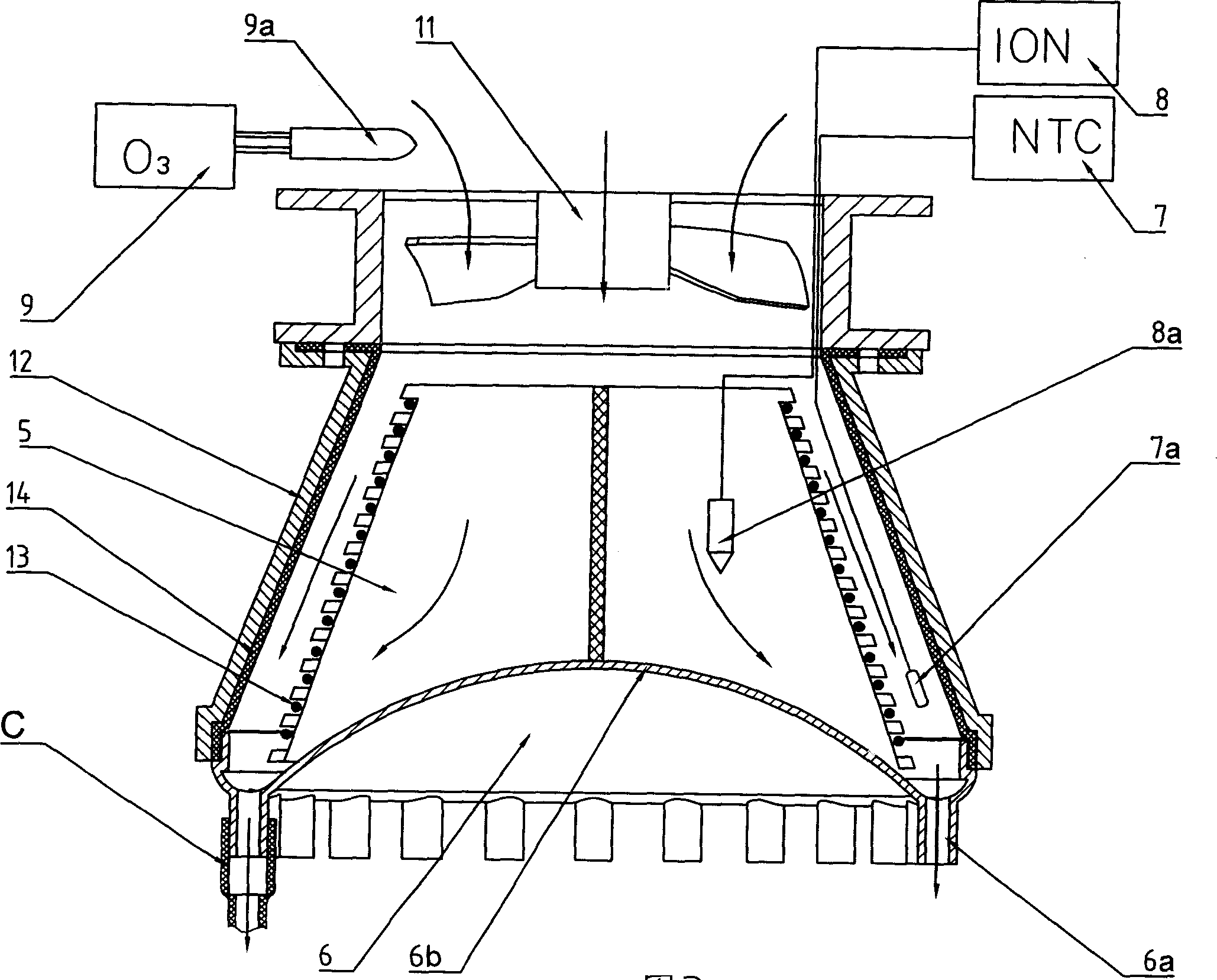

[0032] figure 2 Shows one internal structure of a hot air blower. Heat blower is made up of casing, fan 11, heating wire 13, mica frame 5 etc. The casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com