Method and apparatus for automatic adjustment of thread tension

A technology of tension and input device, which is applied in the field of sewing device and lock seam, to achieve the effect of improving uniformity, reducing labor cost and accurate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Detailed description of the preferred embodiment

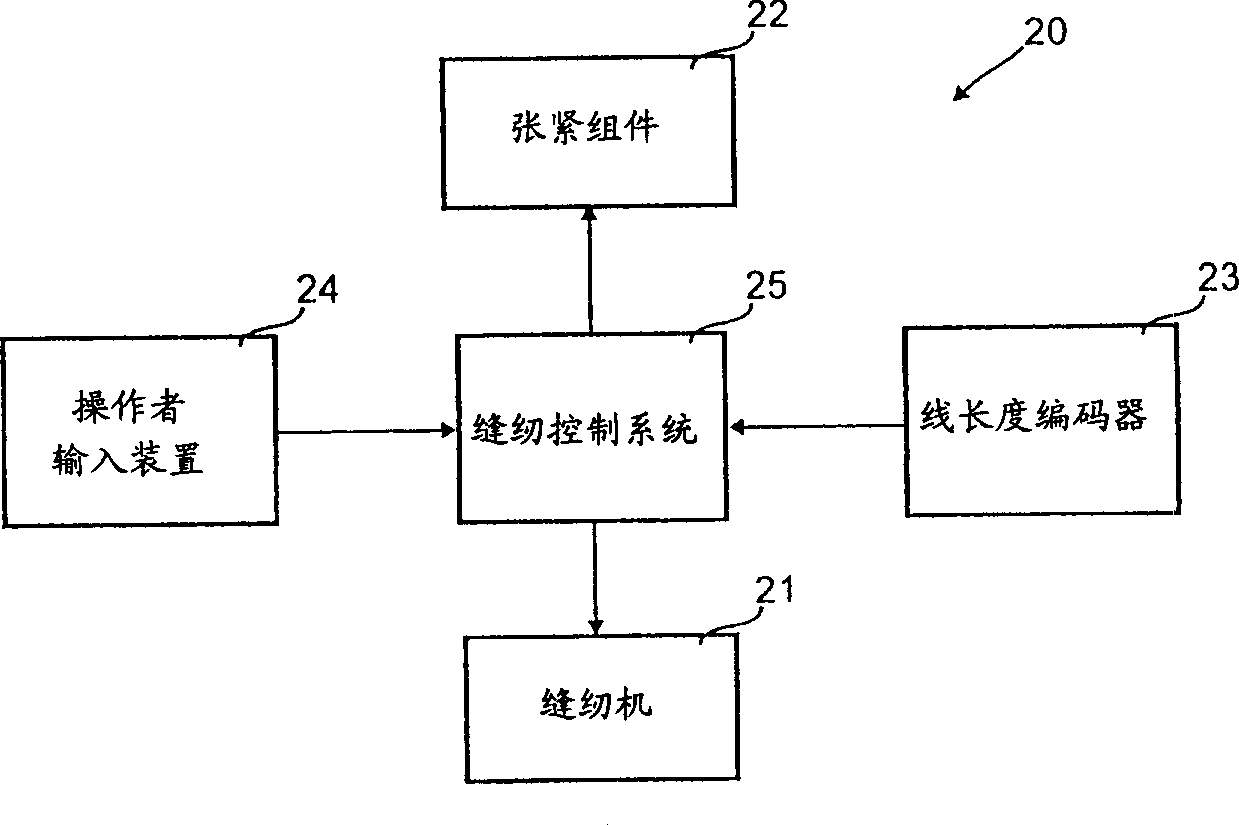

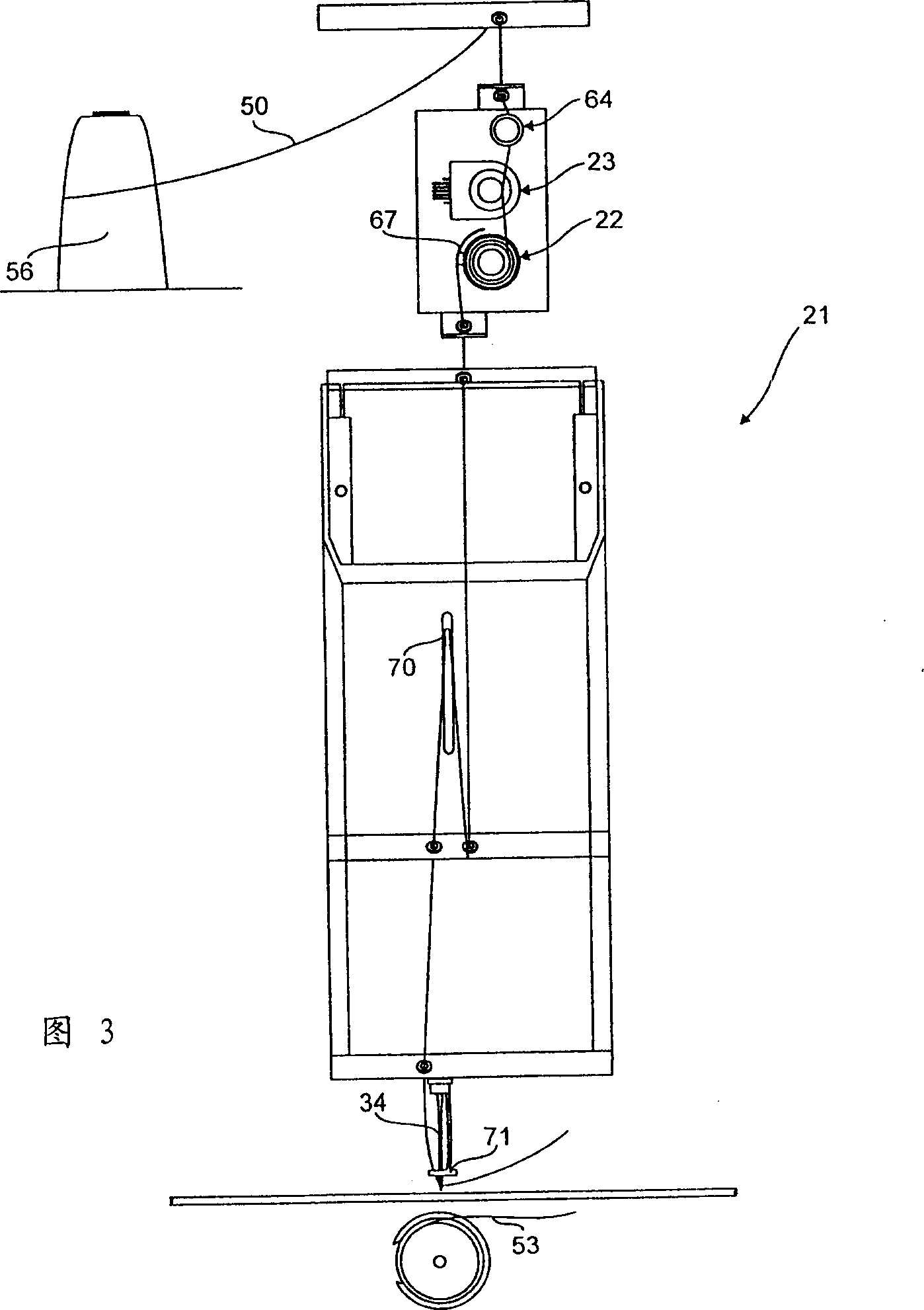

[0054] refer to figure 1 , figure 1 Shown is a block diagram showing the main components of a sewing device. The sewing device 20 includes a tensioning assembly 22 , a thread length encoder 23 , a sewing machine 21 , an operator input device 24 and a sewing control system 25 . The sewing control system 25 includes a computer that receives input from an operator input device 24 and a thread length encoder 23 . These operator inputs are used along with decorative pattern information to determine how sewing control system 25 monitors sewing machine 21 and tensioning assembly 22 as sewing is performed.

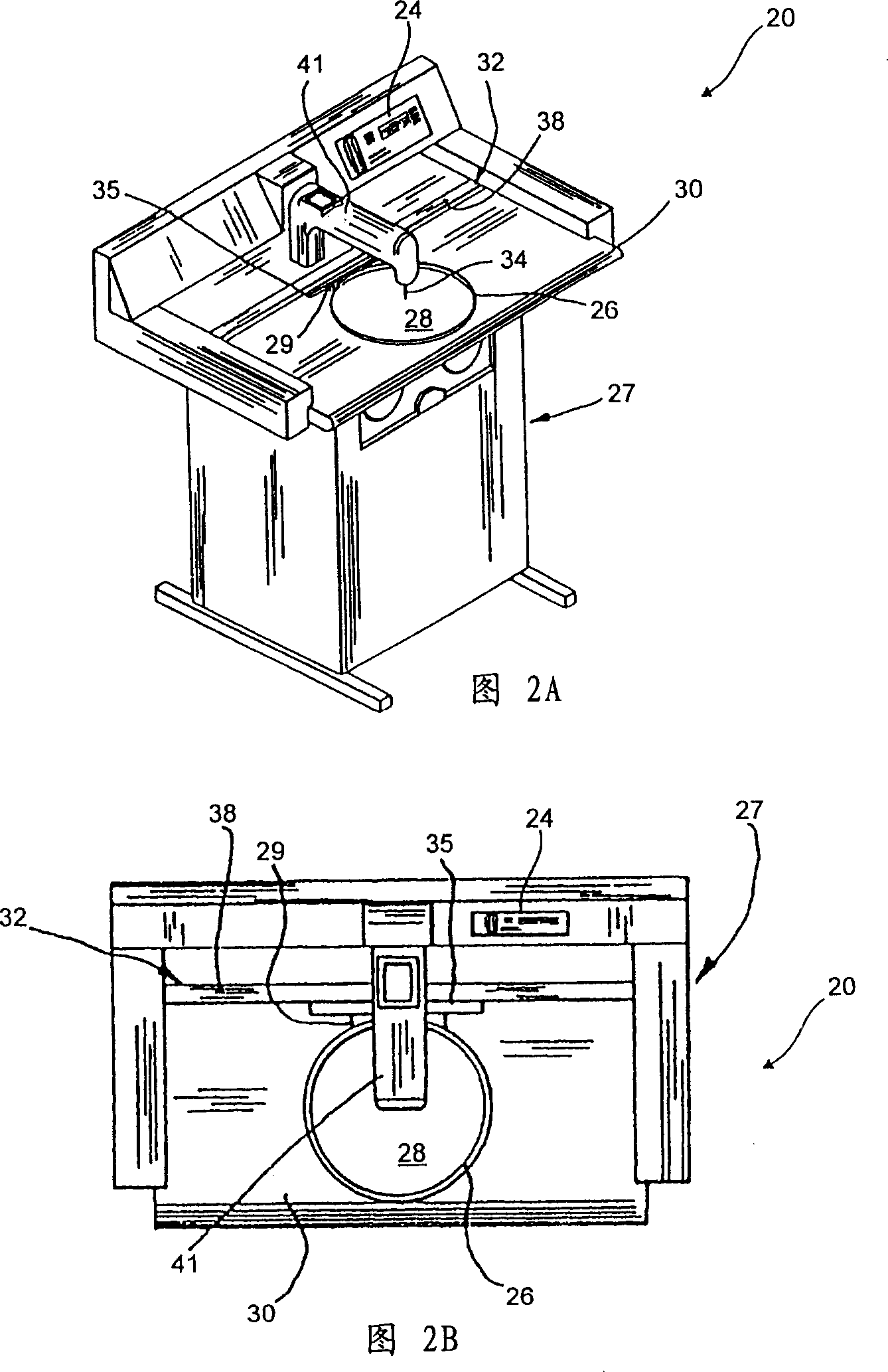

[0055] The sewing machine 21 in the preferred embodiment includes all remaining items needed to complete sewing. Among the remaining items described are: a needle, a drive to move the fabric between two axes, a thread guide, a presser foot, a thread take-up lever, a thread crimp, a thread break detector and a Bottom li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com