Intelligent glove hemming machine having display screen

A technology of display screen and hemming machine, which is applied to the thread cutting mechanism, cloth pressing mechanism, sewing machine components and other directions in the sewing machine, can solve the problems of cumbersome operation process, increased labor cost and large workload of production enterprises, etc. Easy to learn, improve production efficiency and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

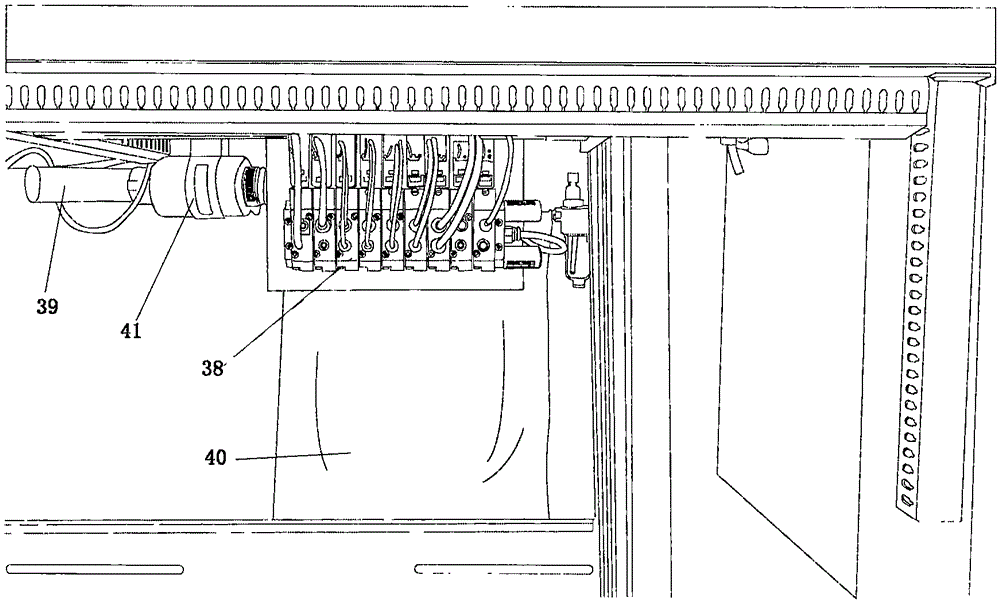

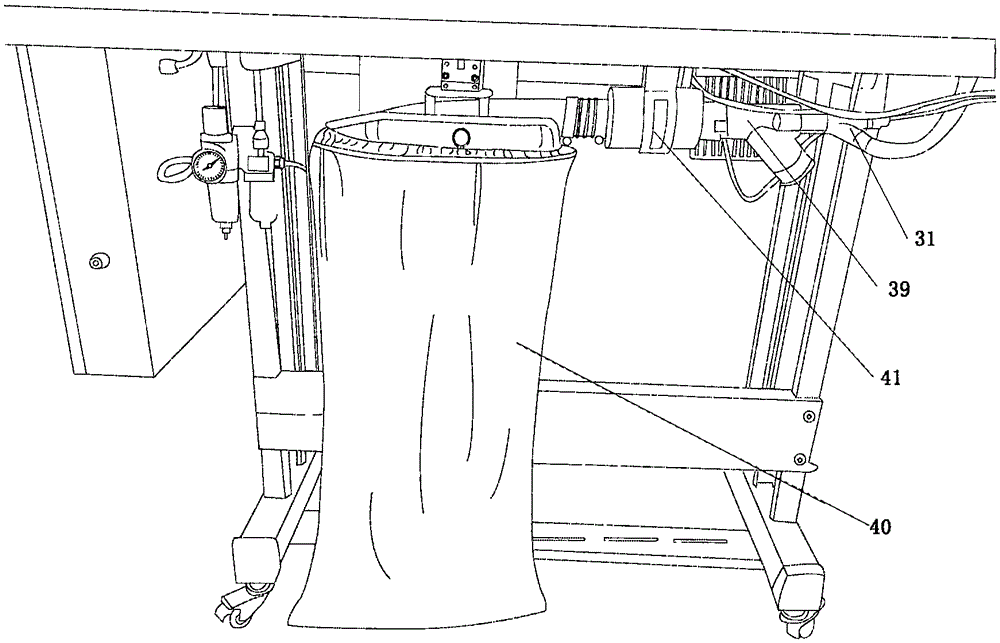

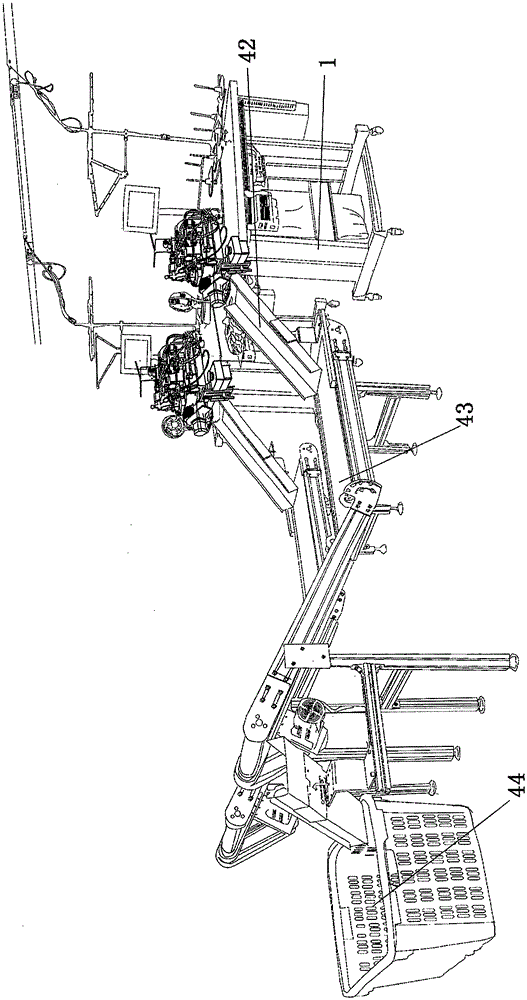

[0025] Such as Figure 1 to Figure 4 As shown, a smart glove hemming machine with a display screen includes a frame 1, a table 2 and a unit assembly 3, the table 2 is fixed on the frame 1, the unit assembly 3 is arranged on the table 2, and the unit Component 3 includes a wire lead device, a machine head device, an elastic feeding device, a thread trimmer, a stripping device and a control device; the wire lead device includes a wire frame 4, a bobbin roller 5, and a thread gripper 6, and the wire frame 4 and the bobbin roller 5 are respectively fixed on the platen 2; machine head device includes machine head 7, servo motor 8, machine head teeth 9, balance weight 10, presser foot 11, stepping motor I12, roller seat 13, roller roller 14, stepping motor II15, rotary gear 16, strut cylinder 17 and strut hook 18, machine head 7 is fixed on the platen 2 by machine head seat 46, and servo motor 8 is fixed on the afterbody of machine head 7 and can drive machine head 7 work, machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com