Elastic yarn conveying device in multi-needle machine

A technology of conveying device and multi-needle machine, applied in sewing machine control devices, thread break detectors, sewing machine components, etc., can solve the problems of short needle life, needle damage, inconsistent needle and thread tightness, etc., to improve work efficiency and save money Parts, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

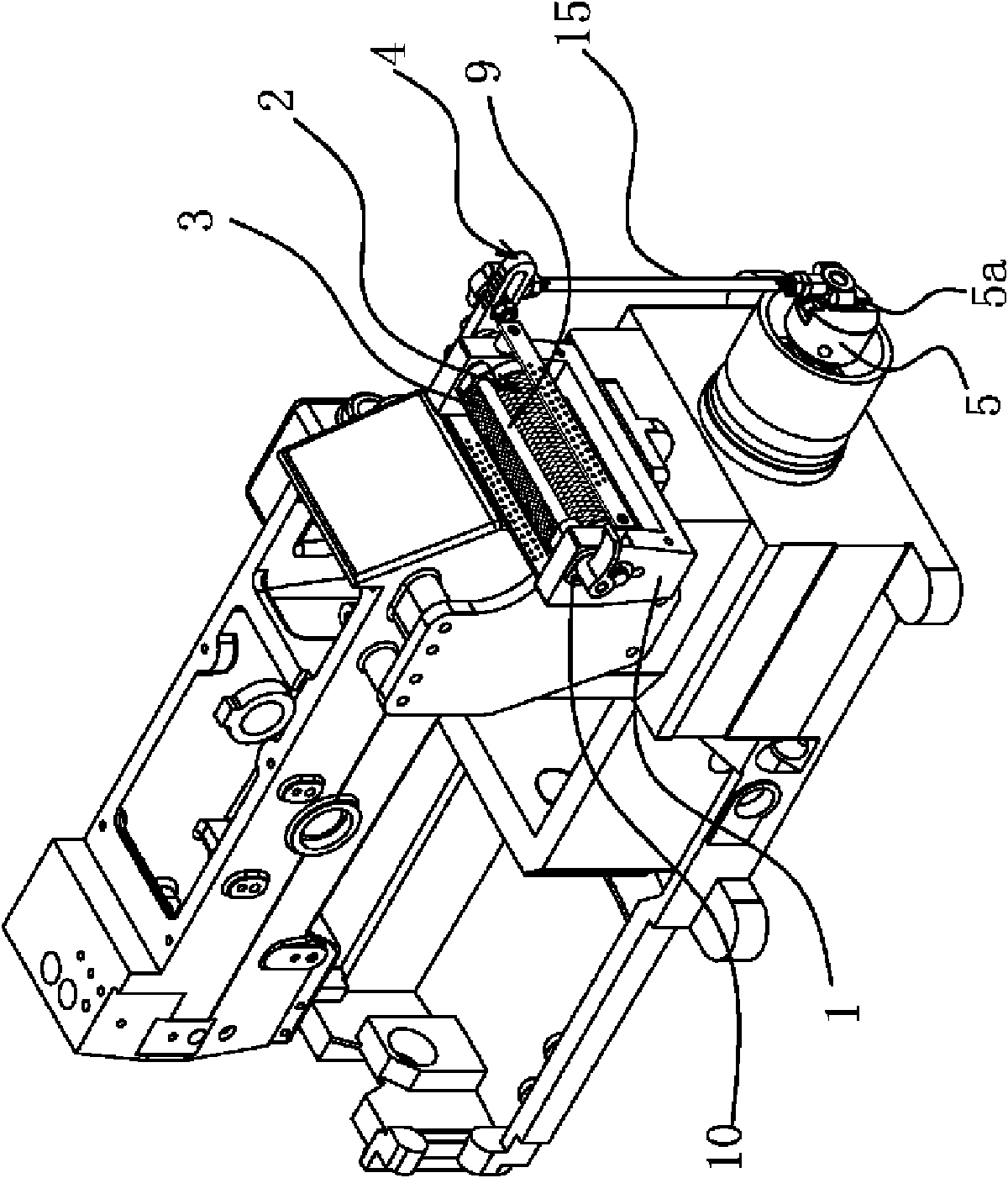

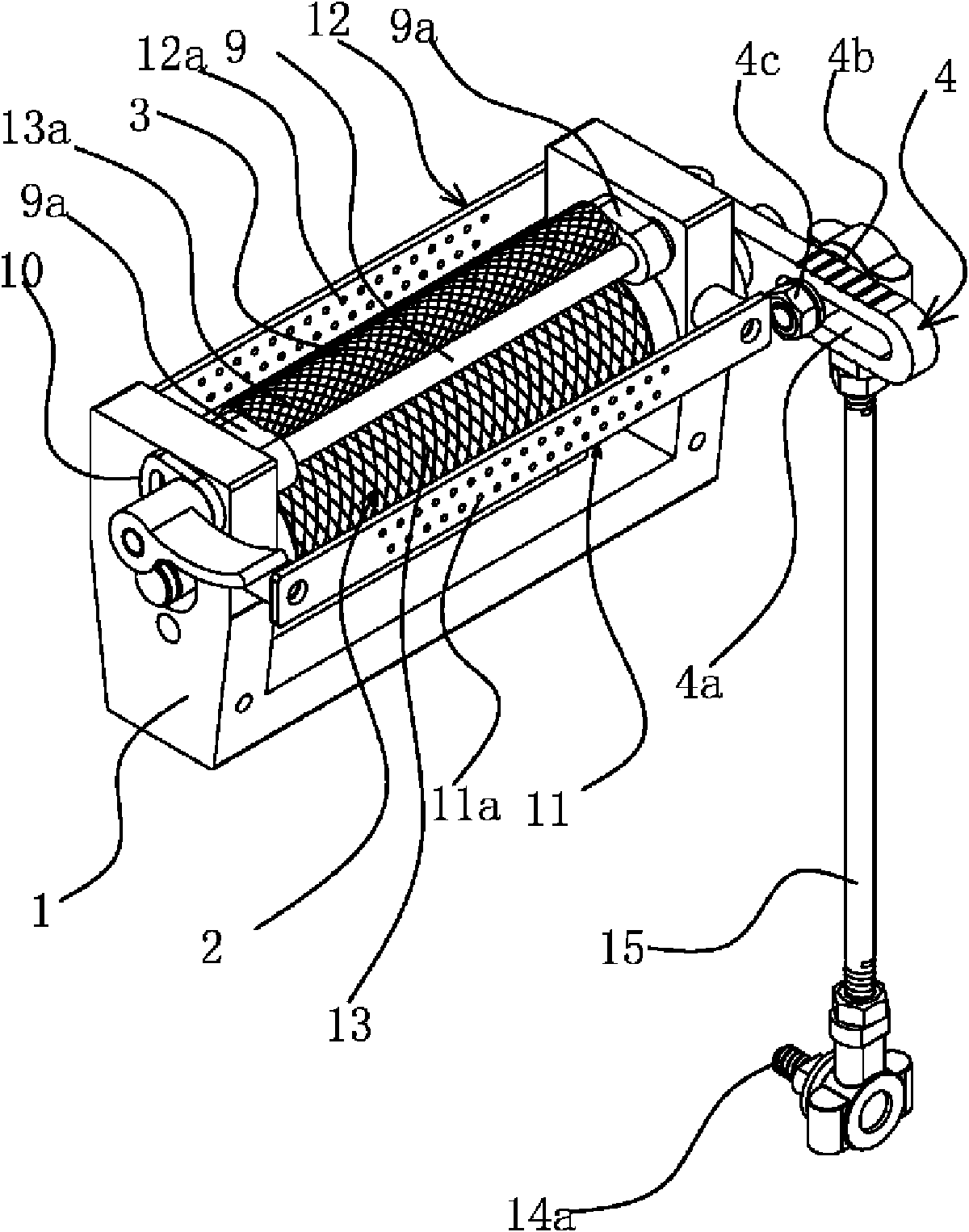

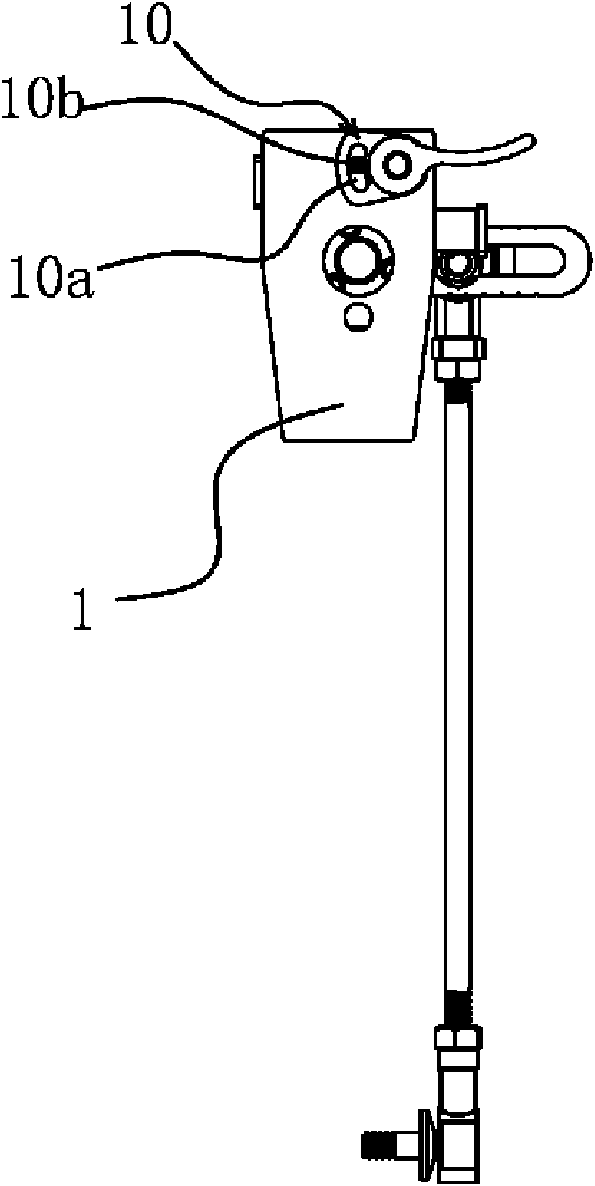

[0026] Such as figure 1 As shown, the elastic thread conveying device in the multi-needle machine is located near the main shaft 5 of the multi-needle machine, including the mounting seat 1, the driving wheel 2, the one-way clutch mechanism, the pressing wheel 3, the crank 4, the adjustment mechanism and the transmission mechanism, etc. .

[0027] Specifically, if figure 2 As shown, the mounting seat 1 is arranged on the frame and is U-shaped. The mounting seat 1 is axially fixed with a driving wheel 2 that can rotate freely around its own axis. The driving wheel 2 is cylindrical and has knurling-13 on the surface. The end faces at both ends have cylindrical inner cavities 2a concentric therewith.

[0028] Such as im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com