Down coat fabric treatment method for preventing down feather from escaping from needle holes

A technology for down jacket fabrics and processing methods, applied in fiber processing, fiber types, textiles and papermaking, etc., can solve the problems of low weight gain and cold resistance, achieve high resilience and smoothness, excellent wearing comfort, and improved elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

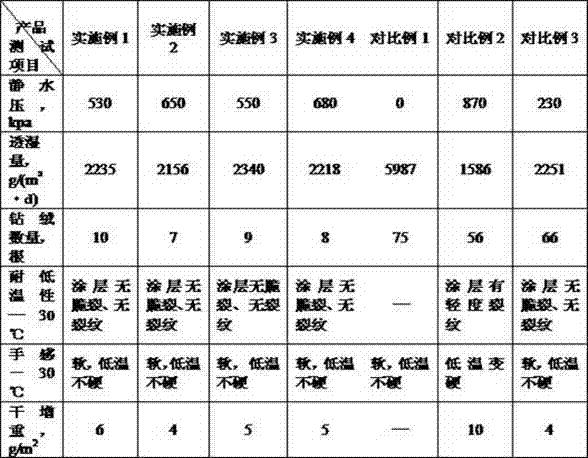

Examples

Embodiment 1

[0037] (1) Fabric selection: plain fabric woven from nylon FDY fully stretched yarn, yarn count 40D*40D, density 290T;

[0038] (2) Water-repellent finishing is carried out on the fabric, and the water-staining level is ≥3;

[0039] (3) Calender the fabric after water-repellent finishing with a calender, with a pressure of 11Mpa, a temperature of 110°C, and a speed of 30 m / min;

[0040] (4) Coating glue preparation, raw material weight ratio:

[0041] 100 parts of polyether polyurethane coating glue;

[0042] 30 parts of hydroxyl-terminated polydimethylsiloxane emulsion;

[0043] 1 part of isocyanate crosslinking agent;

[0044] 1.2 parts of cross-linking accelerator;

[0045] 3 parts of silica matting powder;

[0046] 15 parts of toluene;

[0047] Mix and stir the silica-based matting powder with toluene to fully dissolve, then mix and stir with polyether polyurethane coating glue evenly, then add hydroxyl-terminated polydimethylsiloxane emulsion, isocyanate cross-linki...

Embodiment 2

[0051](1) Fabric selection: plain weave fabric woven with nylon FDY fully stretched yarn, yarn count 20D*20D, density 370T;

[0052] (2) Water-repellent finishing is carried out on the fabric, and the water-staining level is ≥3;

[0053] (3) Calender the fabric after water-repellent finishing with a calender, with a pressure of 9Mpa, a temperature of 100°C, and a speed of 35 m / min

[0054] (4) Coating glue preparation, raw material weight ratio:

[0055] 100 parts of polyether polyurethane coating glue;

[0056] 25 parts of hydroxyl-terminated polydimethylsiloxane emulsion;

[0057] 1.2 parts of isocyanate crosslinking agent;

[0058] 1.5 parts of cross-linking accelerator;

[0059] 3 parts of silica matting powder;

[0060] 15 parts of toluene;

[0061] Mix and stir the silica-based matting powder with toluene to fully dissolve, then mix and stir with polyether polyurethane coating glue evenly, then add hydroxyl-terminated polydimethylsiloxane emulsion, isocyanate cross...

Embodiment 3

[0065] (1) Fabric selection: plain weave fabric woven with nylon FDY fully stretched yarn, yarn count 30D*30D, density 300T;

[0066] (2) Water-repellent finishing is carried out on the fabric, and the water-staining level is ≥3;

[0067] (3) Calender the fabric after water-repellent finishing with a calender, with a pressure of 10Mpa, a temperature of 100°C, and a speed of 35 m / min;

[0068] (4) Coating glue preparation, raw material weight ratio:

[0069] 100 parts of polyether polyurethane coating glue;

[0070] 20 parts of hydroxyl-terminated polydimethylsiloxane emulsion;

[0071] 1.5 parts of isocyanate crosslinking agent;

[0072] 1.8 parts of cross-linking accelerator;

[0073] 4 parts of silica matting powder;

[0074] Butanone 15 parts;

[0075] Mix and stir the silica-based matting powder with toluene to fully dissolve, then mix and stir with polyether polyurethane coating glue evenly, then add hydroxyl-terminated polydimethylsiloxane emulsion, isocyanate cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com