Warm-keeping down jacket capable of preventing down leakage

A down jacket and leak-proof down technology, which is applied in clothing, garments, outerwear, etc., can solve the problems of poor wearing comfort, poor operability, and warmth retention of down, and achieve the effect of enhancing the heat preservation effect and solving the problem of down drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

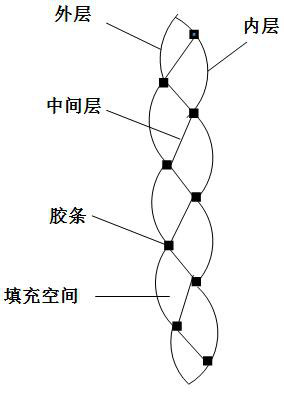

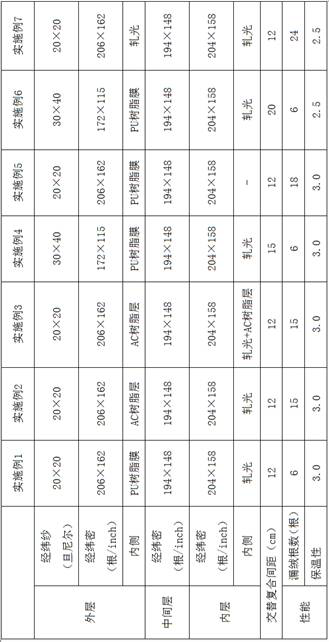

[0031] The nylon fiber plain weave fabric with a warp and weft density of 206×162 threads / inch and a PU resin film on the inside is used as the outer fabric, and the nylon fiber plain weave fabric with a warp and weft density of 194×148 threads / inch is used as the middle layer fabric, and the warp and weft density is 204 × 158 threads / inch and calendered nylon fiber plain fabric on the inside as the inner layer fabric, wherein the warp and weft yarns forming the outer layer fabric are both 20D in fineness.

[0032] According to the required style and size of the garment, the outer layer, the middle layer and the inner layer fabric are cut into garment pieces. First put the inner garment piece on the garment piece area of the template, and then stick a 5mm-wide PU glue strip on the inner garment piece. The two ends of the glue strip are attached to the double-sided glue points of the template. The distance between them is 12cm, and then the middle layer of clothing is put on,...

Embodiment 2

[0035] A nylon fiber plain weave fabric with a warp and weft density of 206×162 threads / inch and an AC resin layer inside is selected as the outer layer fabric, and the rest is the same as in Example 1 to obtain the down jacket of the present invention. See Table 1 for details.

Embodiment 3

[0037] Select the nylon fiber plain weave fabric that is first calendered on the inside and then coated with an AC resin layer as the inner layer fabric, and the rest are the same as in Example 2 to obtain the down jacket of the present invention. See Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com