Method for preparing oily electrothermal conversion ink, and ink prepared by preparation method

An electric heating and ink technology, applied in ink, household utensils, applications, etc., can solve the problems of too many hydrophilic groups on the surface, difficult to control printing quality, poor printability, etc., achieve simple curing conditions, improve adaptability, and resist The effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

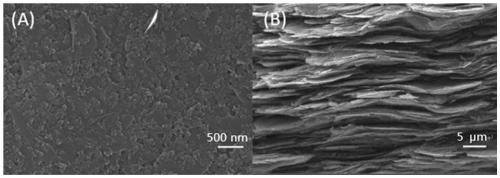

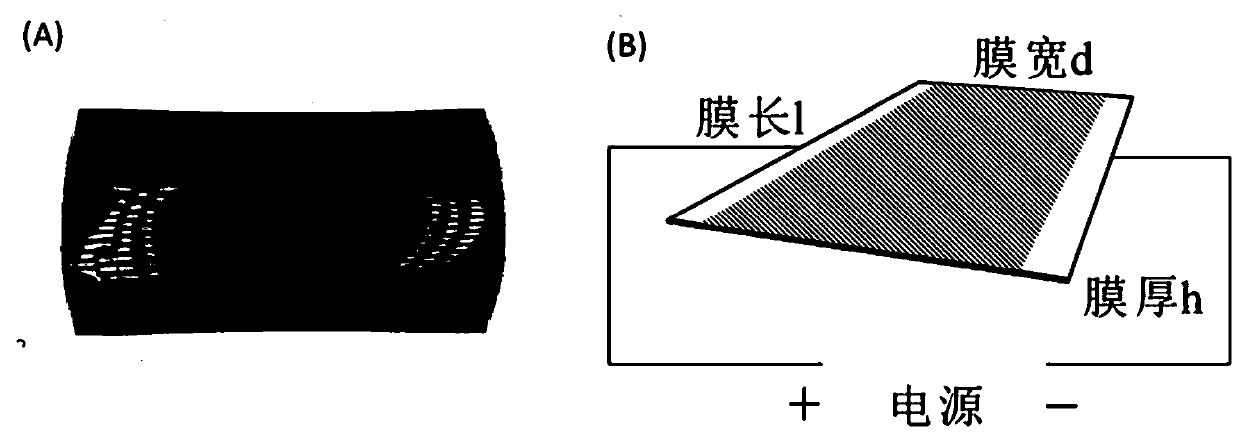

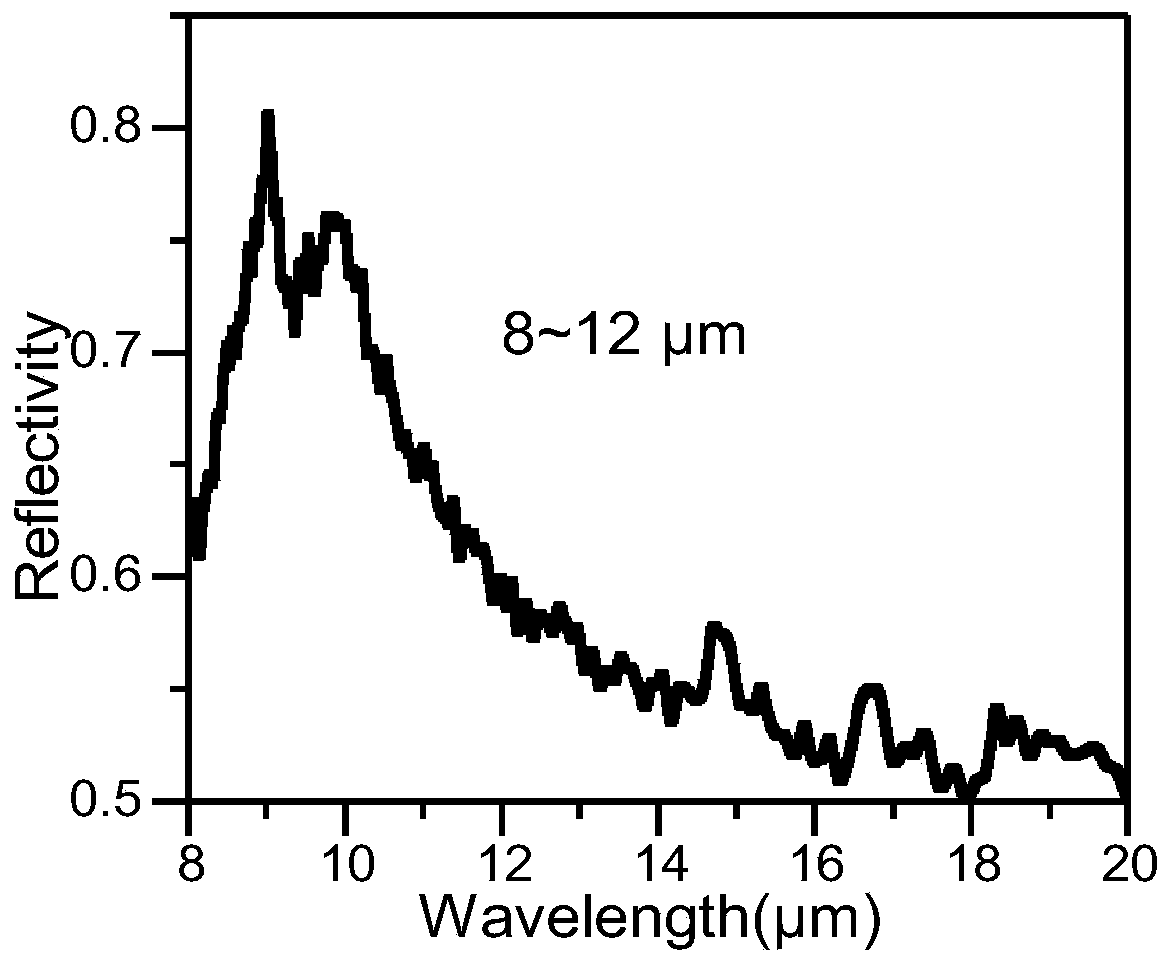

[0045] According to the present invention, the expanded graphite of 450 times ratio is mechanically pulverized to D50=200μm to obtain pulverized expanded graphite; the pulverized expanded graphite and conductive carbon black are respectively composed of two-component fillers at a mass ratio of 8:1 ; Mix the two-component filler 10%, acrylic resin 25%, rheology additive castor oil (the amount of conductive filler is 5%), silane coupling agent KH-560 (the amount of conductive filler is 1%) And the rest is a mixed solvent composed of terpineol and ethanol in a mass ratio of 3:7 to obtain a mixture; stir the mixture with a high-speed mixer for more than 10 minutes to obtain a uniform and non-foaming ink precursor dispersion; the ink precursor The body dispersion is ball milled to a fineness of less than 20 μm, and the viscosity is 1000 to 13000 mPa·s according to different printing methods to obtain an oil-based electrothermal conversion ink. Its physical and chemical characteristic...

Embodiment 2

[0064] According to the present invention, 250-fold expanded graphite is pulverized by airflow to D50=200μm to obtain pulverized expanded graphite; the pulverized expanded graphite, high-purity nickel powder and conductive carbon black are respectively in a mass ratio of 1:8:1 To form a three-component filler; mix the three-component filler 20%, epoxy resin 10%, dispersant polyethylene glycol 100 (the amount is 10% of the mass of the conductive filler), rheology additive silica (the amount 2% of the amount of conductive filler), silane coupling agent KH-550 (the amount of 0.1% of the amount of conductive filler) and the rest is a mixed solvent composed of propylene glycol n-propyl ether and DBE in a mass ratio of 1:3 to obtain Mixture; Stir the mixture with a high-speed mixer for more than 10 minutes to obtain a uniform and non-foaming ink precursor dispersion; sand the ink precursor dispersion to a fineness of less than 20μm, and a viscosity of 1000 to 13000mPa according to dif...

Embodiment 3

[0066] According to the present invention, the expanded graphite of 600 magnification is pulverized by airflow to D50=25μm to obtain pulverized expanded graphite; the pulverized expanded graphite, carbon nanotubes and conductive carbon black are respectively in a mass of 3:1:2 The ratio constitutes a three-component filler; mixing the three-component filler 4%, epoxy resin 10%, polyurethane resin 5%, dispersant sodium dodecylbenzene sulfonate (the amount of conductive filler is 3%), flow Bentonite (the dosage is 1.5% of the conductive filler), the silane coupling agent A-171 (the dosage is 5% of the conductive filler) and the rest are ethyl acetate and 1-methyl-2 pyrrolidone according to 3: A mixed solvent composed of a mass ratio of 2 to obtain a mixture; stir the mixture with a high-speed mixer for more than 10 minutes to obtain a uniform and non-foaming ink precursor dispersion; the ink precursor dispersion is milled to a low fineness through three rollers At 20μm, the visco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com