Process for preparing selective emitter of monocrystalline silicon solar cell with corrosion slurry method

A solar cell and emitter selection technology, applied in sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of complex process, poor emitter effect, and high equipment requirements, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following drawings and in conjunction with the embodiments further illustrate the present invention.

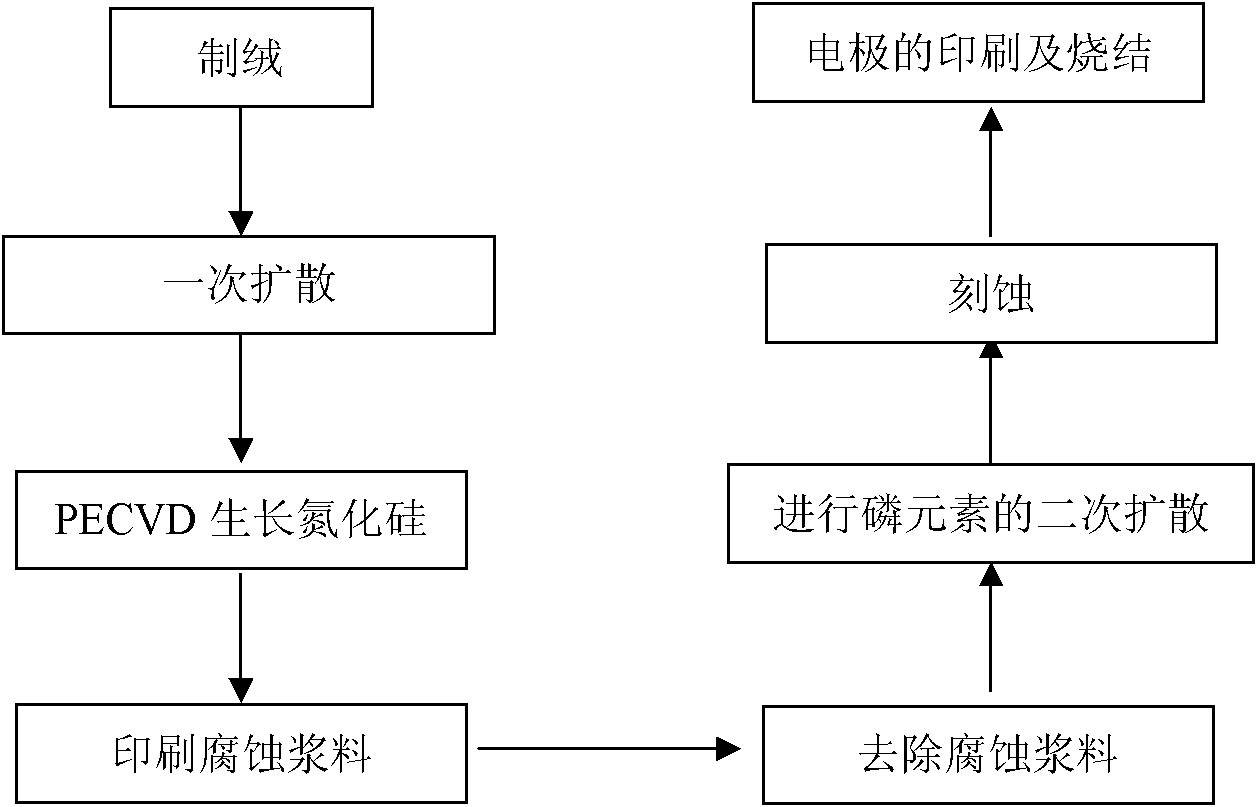

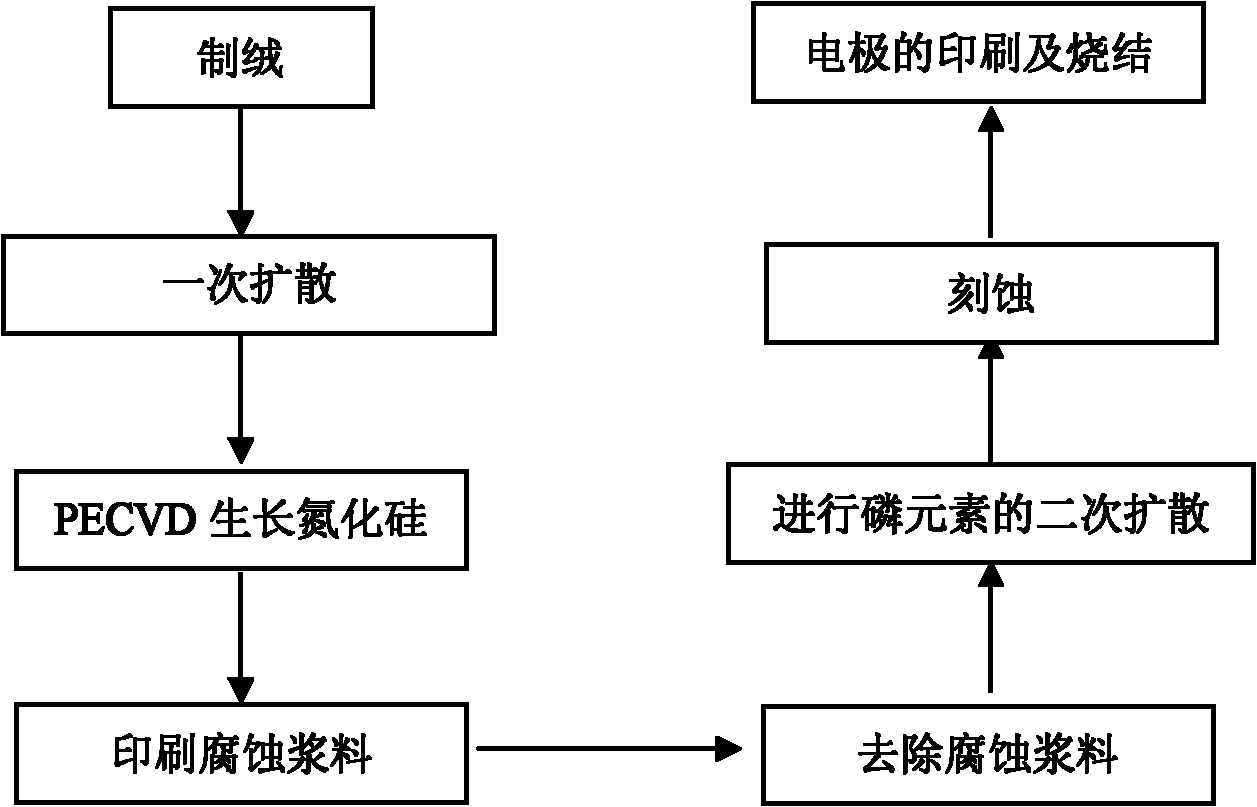

[0030] Such as figure 1 As shown, a process for preparing selective emitters of single crystal silicon solar cells using the corrosion slurry method, in which texturing, diffusion, PECVD growth anti-reflection film, printing and sintering of electrodes and detection of cell conversion efficiency are all used to prepare single crystal silicon solar cells. The general process of silicon solar cells, growth of silicon dioxide barrier layer, printing of corrosion paste, removal of corrosion paste and secondary diffusion of phosphorus elements are the processes involved in the preparation of selective emitters in this patent. The following steps are specifically introduced:

[0031] A silicon nitride barrier layer is grown on the front of the cell after diffusion. The grown silicon nitride layer not only serves as a barrier layer for secondary diffusion, but also as an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com