Method for preparing L10 ordered alloy film

A technology of ordered alloys and alloy films, applied in metal material coating process, ion implantation plating, coating and other directions, to avoid grain growth, simplify the preparation process, and achieve the effect of small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

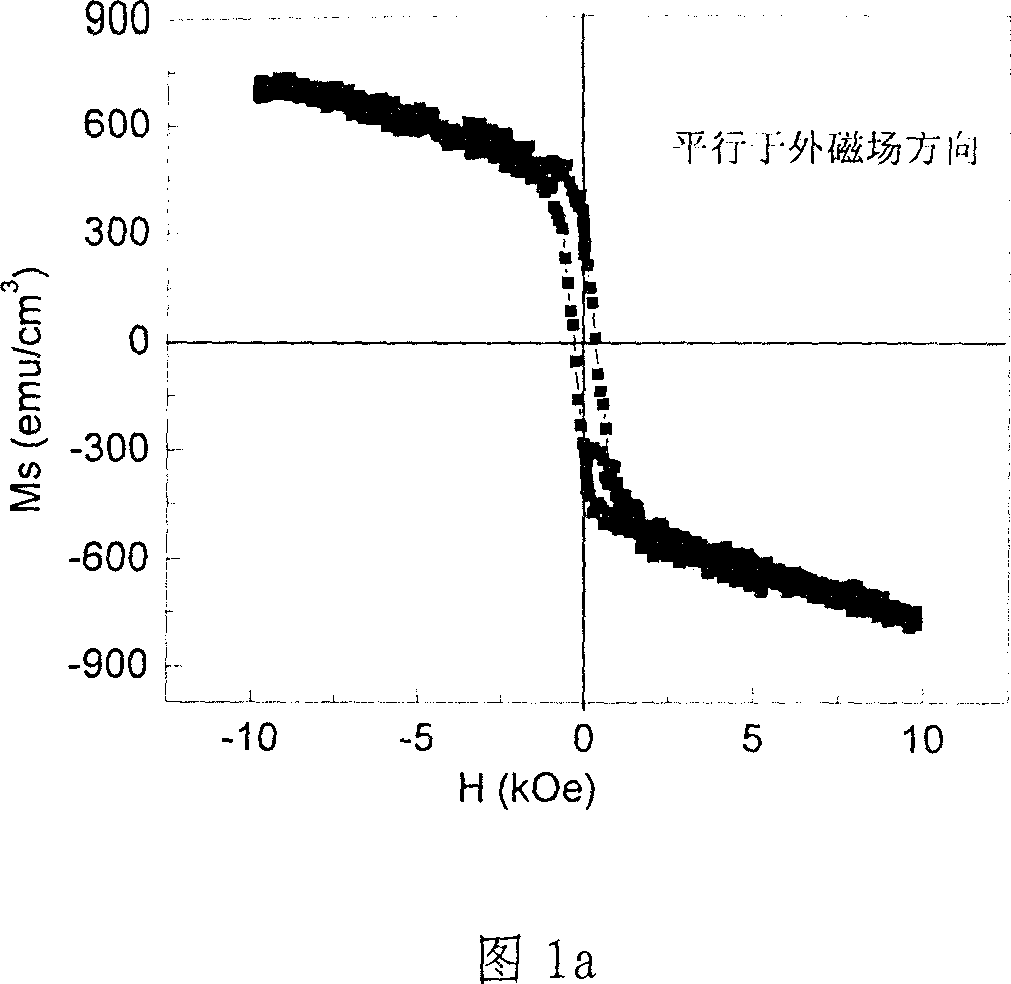

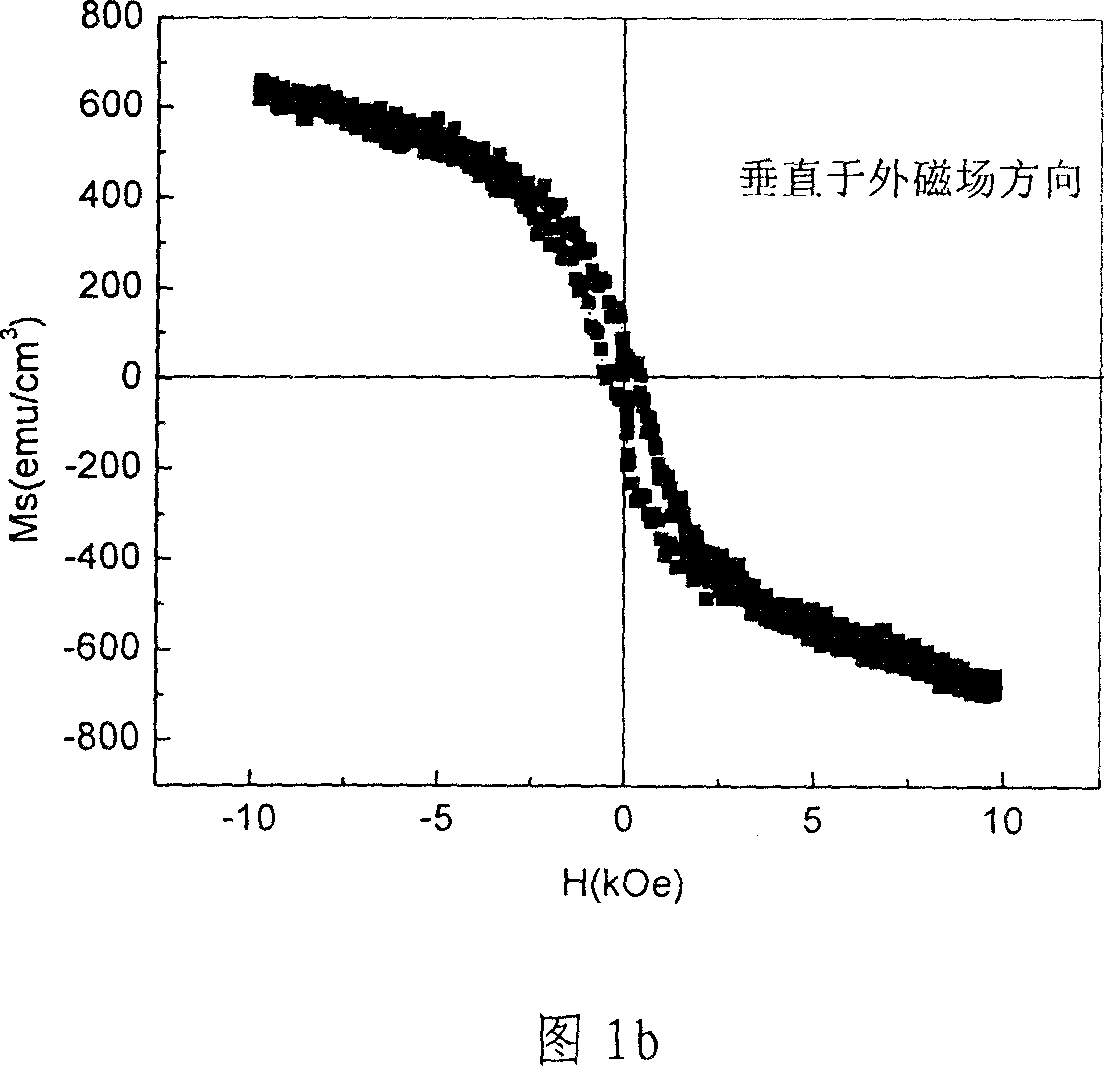

[0018] With oriented single crystal silicon wafer as the substrate, the Si / FePt / SiN three-layer film structure was prepared by magnetron sputtering. The background vacuum during sputtering is 1*10 -4 Pa, Ar is used as the sputtering gas, and the sputtering pressure is 1 Pa. The FePt film was sputtered with a DC composite target, the sputtering power was 25W, the sputtering time was 10min, the diameter of the Fe target was Φ50, the size of the Pt piece was 5*5mm, and the purity was 99.99%. The SiN film as a protective layer is sputtered by radio frequency reactive sputtering with Ar and N 2 Commonly used as sputtering gas, P Ar : P N2 =1:1, sputtering time is 8min. All films are prepared at room temperature. Laser annealing uses Ar with a wavelength of 514nm + The laser is used as the light source, and the laser is continuous light. The Gaussian radius of the spot is about 0.9mm. The laser scanning speed is 5mm / s, and the laser power is set to 12W. The laser light is incident from...

Embodiment 2

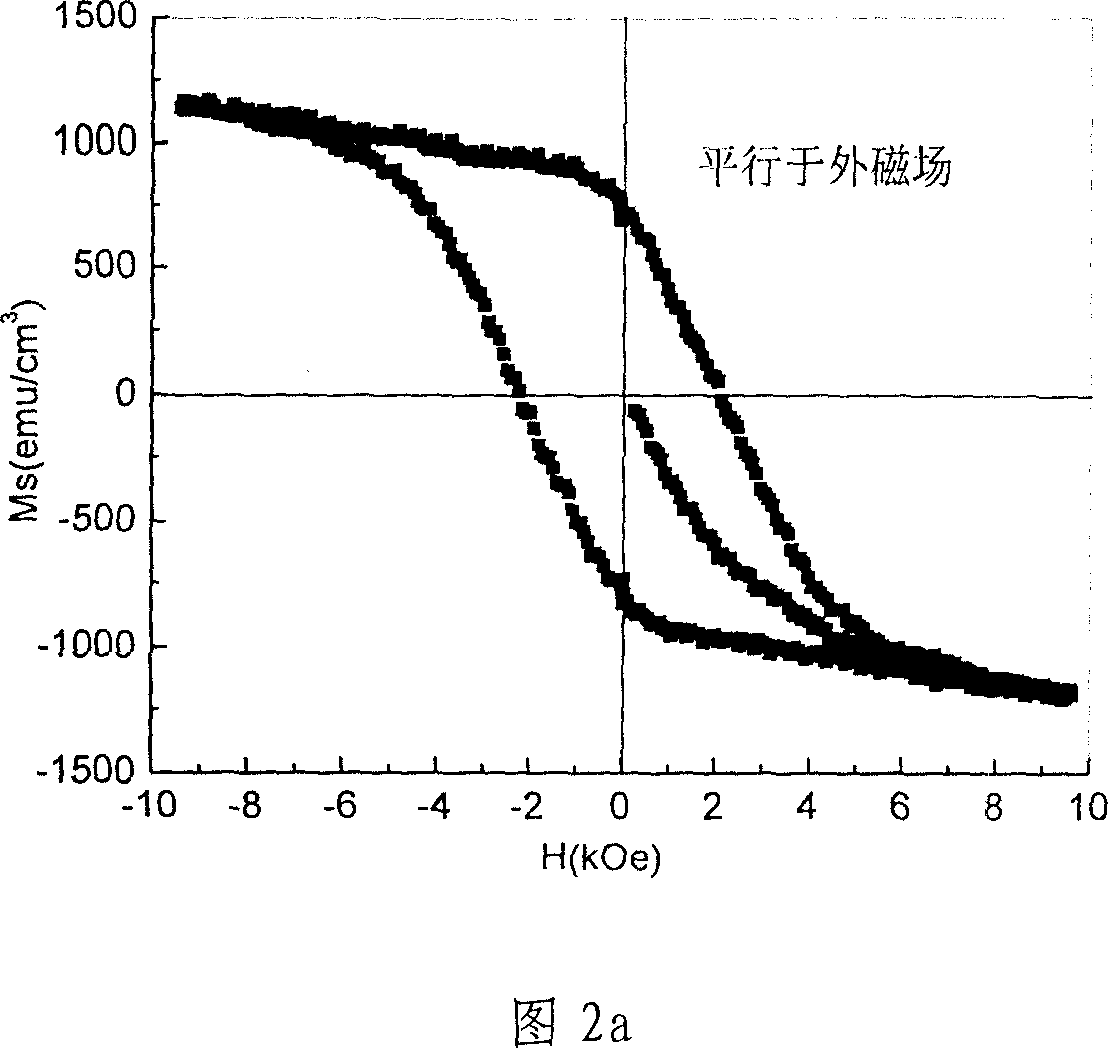

[0020] With MgO single crystal as the substrate and Pt as the buffer layer, the MgO substrate / Pt / FePt / SiN was prepared by magnetron sputtering. The preparation methods of FePt and SiN films were the same as in Example 1, and the purity of Pt film was 99.99 % Pt target DC sputtering for 5min. The laser annealing method is the same as in Example 1. Figures 3a and 3b are comparisons of X-ray diffraction patterns of the film before and after laser irradiation. It can be seen that before annealing, the FePt film has a strong (111) diffraction peak, a (001) diffraction peak is very weak, and a (002) diffraction peak does not appear, which indicates that the film has a typical fcc disordered structure at this time. After laser annealing, the intensity of the (111) diffraction peak is weakened, and the intensity of the (001) diffraction peak and (002) diffraction peak are obviously enhanced. This shows that the fct ordered phase has appeared. Further increase the laser power or slow down ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser intensity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com