Energy compensation constant power density laser oblique impact method

An energy compensation and equal power technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as uneven laser shock strengthening effects, avoid uneven strengthening effects, improve distribution uniformity, and reduce roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

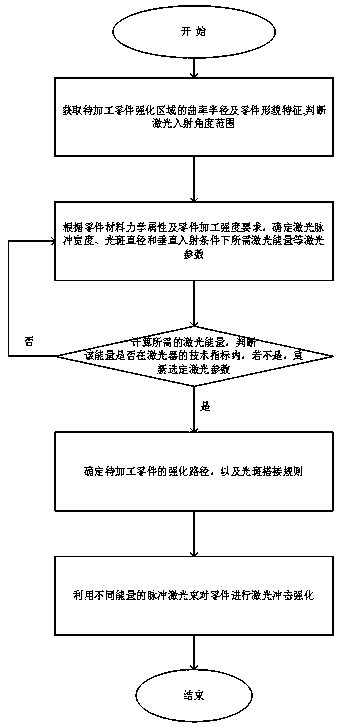

[0035] Such as Figure 1 to Figure 4 Shown is the first embodiment of the energy compensation equal power density laser oblique impact method of the present invention, including the following steps:

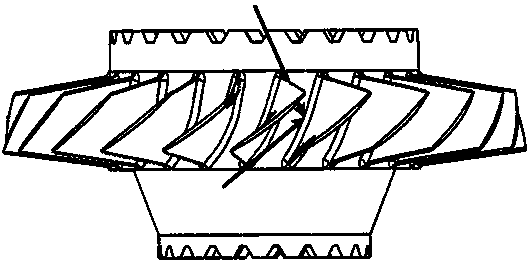

[0036] S1. Obtain the radius of curvature R of the arc strengthening area of the part to be processed and the shape characteristics of the part to be processed, judge the range of laser incident angle α, and obtain the minimum incident angle α min ; In this embodiment, the laser incident angle α range is α min ≤α<90°; the part to be processed in this embodiment is an impeller including blisks and blades, and the arc area is set at the connection between the blisks and the impeller.

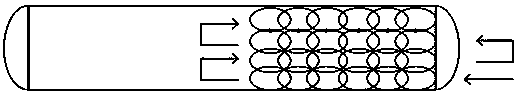

[0037] S2. Determine the laser parameters according to the mechanical properties of the parts to be processed and the processing strength requirements of the parts to be processed. The laser parameters include laser pulse intensity, spot diameter D and laser energy E required under normal incidenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com