Method for measuring thermal conductivity of single semiconductor nanowire material

A nanowire and semiconductor technology, applied in the field of thermal conductivity measurement of a single semiconductor nanowire material, can solve the problems of expensive microfabrication equipment, influence of thermal conductivity of samples, complicated and tedious manufacturing process of microstructure devices, etc., to avoid damage, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

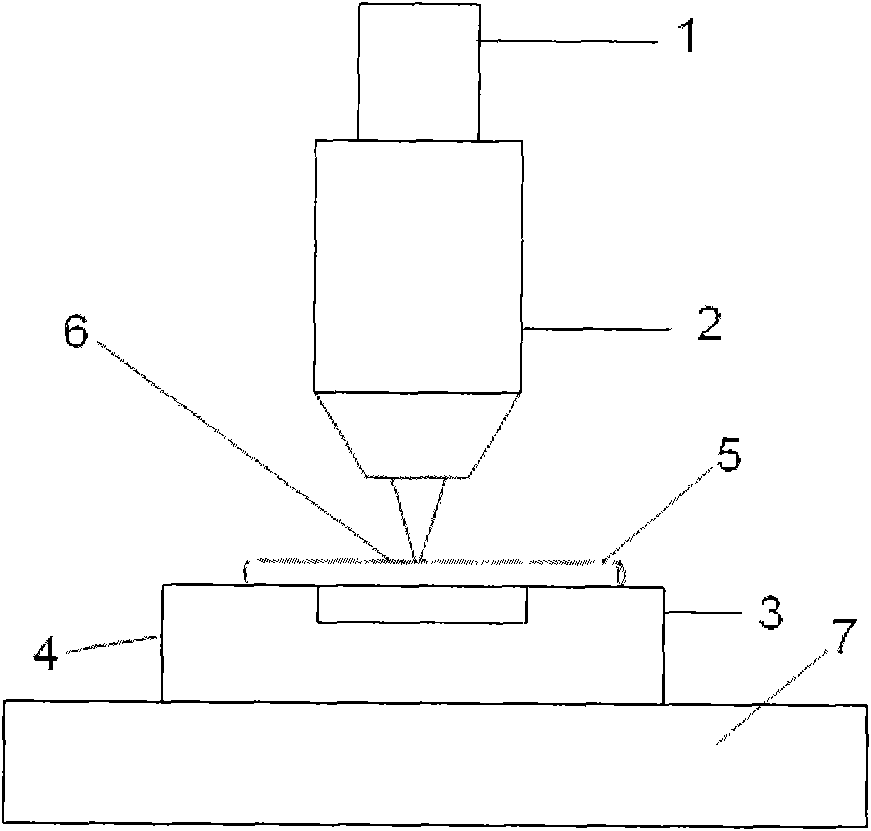

[0040] In this embodiment, the method of the present invention is used to measure the thermal conductivity of a single semiconductor CdS nanowire, and the specific steps are as follows:

[0041] Step 1. Utilize the FIB technology to etch a group of (5 grooves) grooves 4 on the surface of the cleaned silicon substrate 3, the width of the grooves 4 is 5 microns, the length is 100 microns, and the depth is 0.8 microns; The cross-sectional shape of the groove 4 is rectangular; the purpose of etching the groove is to generate a local temperature when the laser is focused on the suspended part of the nanowire;

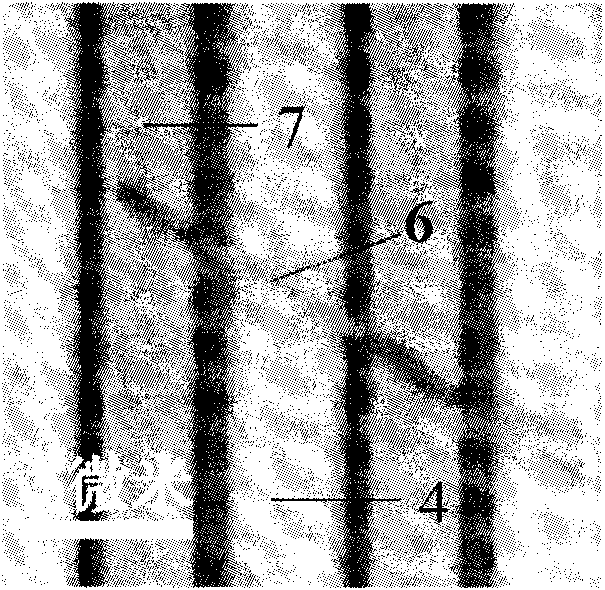

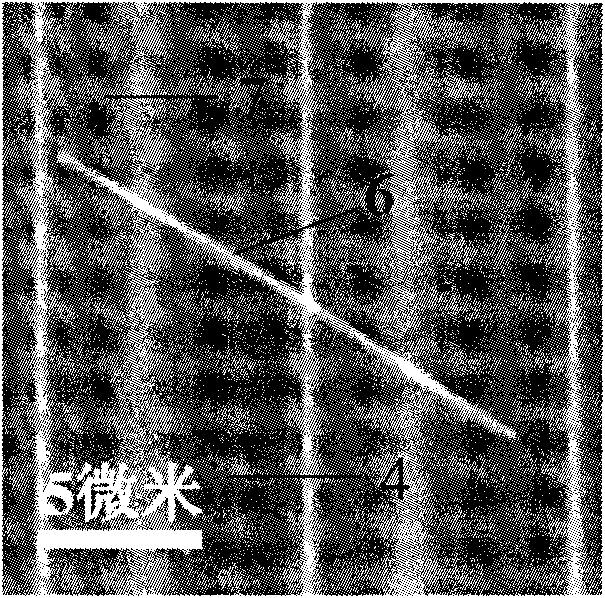

[0042] Step 2. Obtain a single CdS nanowire 6 suspended above the groove 4 by spin-coating an alcohol solution of the CdS nanowire. In order to improve the efficiency of hanging on the groove, the microprobe operation method can also be used to directly manipulate a single semiconductor CdS nanowire 6 and place it on the Si substrate groove 4; see Figure 2a , showing an op...

Embodiment 2

[0056] For the measurement of the thermal conductivity of a single ZnO nanowire, the measurement method and steps in this example are the same as those in Example 1. In this embodiment, the difference from Embodiment 1 is:

[0057] The substrate is an ITO substrate etched with grooves.

[0058] The cross-section of the groove is semicircular, the number of grooves is 10, the width of the groove is 6 microns, the depth of the groove is 0.5 microns, and the length of the grooves is 100 microns.

[0059] Described excitation light source is the 325nm laser that can excite ZnO band edge fluorescence, and the diameter of laser spot (D 2 =2) microns, the laser energy distribution is Gaussian distribution.

[0060] The size of the ZnO nanowires, according to electron micrographs nanowire diameter (D 1 = 0.3 microns).

[0061] According to the step in embodiment 1, obtain and calculate every parameter of single ZnO nanowire, namely the diameter (D of ZnO nanowire to be measured) ...

Embodiment 3

[0063] Measuring the thermal conductivity of a single semiconducting ZnS nanowire

[0064] The method and steps of measuring the thermal conductivity of the nanowires in Example 1 are the same, and the thermal conductivity of a single ZnS nanowire is measured. In this embodiment, the difference from Embodiment 1 is:

[0065] The substrate is a gold-plated Si substrate etched with grooves.

[0066] The cross-section of the groove is rectangular, the number of grooves is 2, the width of the groove is 5 microns, the depth of the groove is 0.7 microns, and the length of the grooves is 100 microns.

[0067] Described excitation light source is the 405nm laser that can excite ZnS band edge fluorescence, and the diameter of laser spot (D 2 =2) microns, the laser energy distribution is Gaussian distribution.

[0068] The size of the ZnS nanowires, according to electron micrographs nanowire diameter (D 1 = 0.35 microns).

[0069] According to the step in embodiment 1, obtain and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com