Laser cleaning device

A laser cleaning and laser technology, applied in cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as low cleaning efficiency, residual scanning fold lines, and restricted applications, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

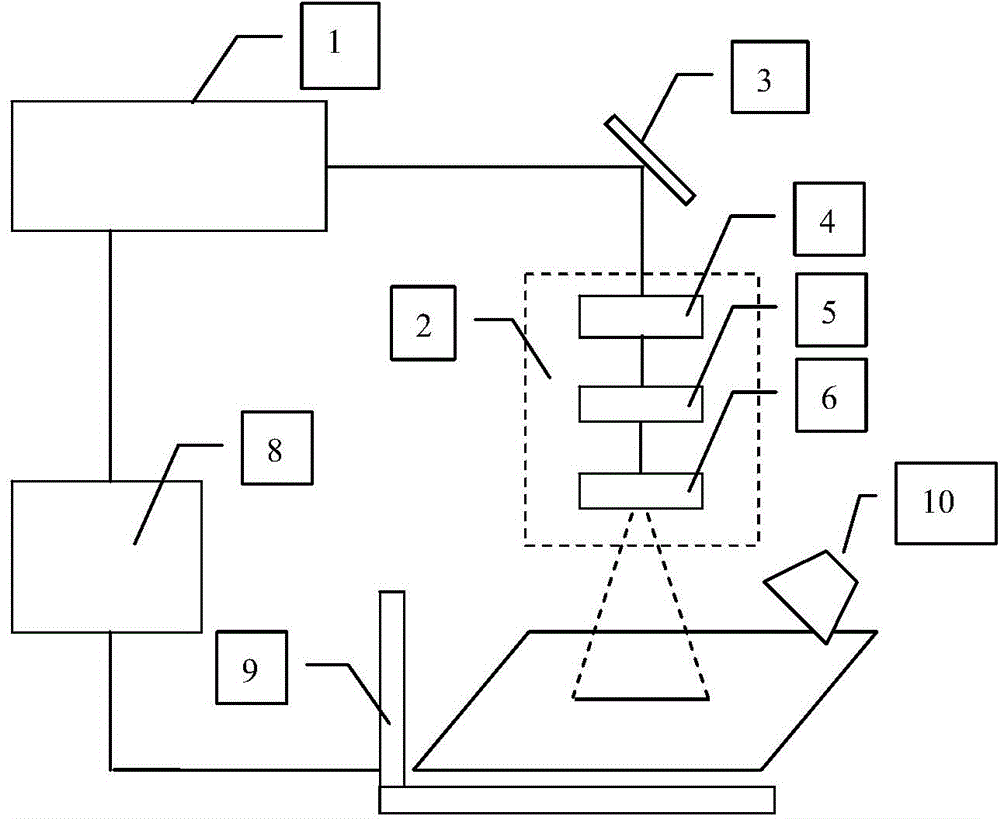

[0022] figure 1 , figure 2 Shown is a laser cleaning device of the present invention. to combine figure 1 As shown, the laser cleaning device includes a laser 1 , a spot generating mechanism 2 , a reflector 3 , a control mechanism 8 , a moving table 9 , and a dust suction mechanism 10 .

[0023] The laser 1 is a high-power continuous laser 1 for emitting laser beams. The laser 1 is one of fiber laser, disk laser, semiconductor laser or carbon dioxide laser 1, and the power of the laser 1 is greater than 500W. The power of the continuous laser has reached tens of thousands of watts, and through external modulation, it can achieve pulsed light above 10KHz, and can achieve efficient removal of large-format paint, rust, and oil.

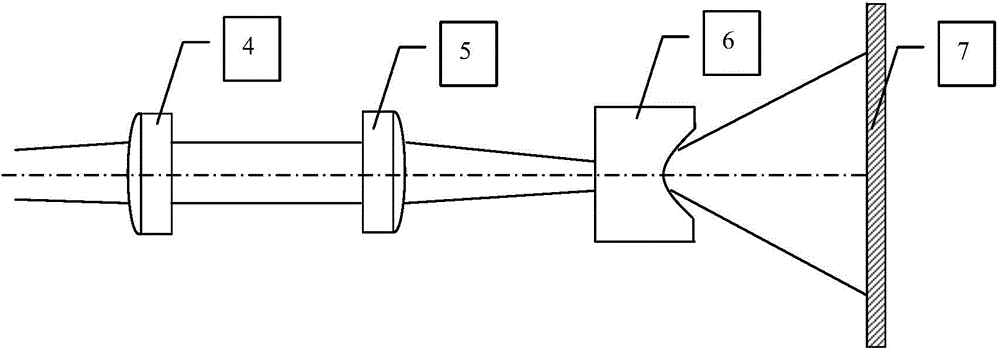

[0024] combine figure 2 As shown, the spot generating mechanism 2 includes a collimating mirror 4 and a lens group sequentially arranged in the outgoing optical path of the laser beam. Specifically in this embodiment, the lens group inc...

Embodiment 2

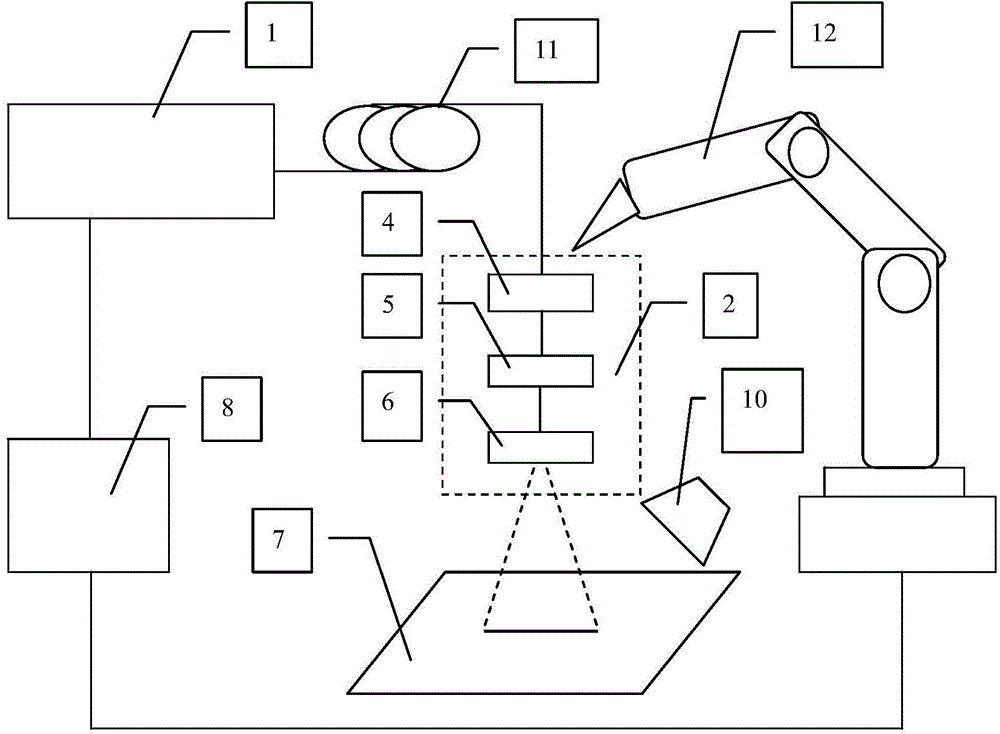

[0031] This embodiment is basically the same as Embodiment 1, combining image 3 As shown, the difference lies in the following two parts: 1. In this embodiment, a transmission fiber 11 is used to transmit the laser beam emitted by the laser 1 to the spot generating mechanism 2, instead of being reflected by the mirror 3, and the two ends of the transmission fiber 11 are respectively connected to the laser 1 and the input end of the spot generation mechanism 2; 2. In this embodiment, the robot arm 12 is used to clamp and fix the spot generation mechanism 2, and the scanning is performed by moving the spot generation mechanism 2 instead of moving the mobile workbench. The robot arm 12 and the control mechanism 8 The phase electrical connection is driven by the control mechanism 8 to drive the spot generating mechanism 2 to scan the workpiece 7 according to the preset moving speed and moving path, and the dust suction mechanism 10 is arranged above the robot arm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com