Method and device for strengthening metal material through pulse current coupled laser peening

A metal material, laser peening technology, applied in the field of metal material strengthening, can solve the problem of small compressive stress amplitude, achieve the effect of increasing amplitude and depth, excellent comprehensive mechanical properties, tensile strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

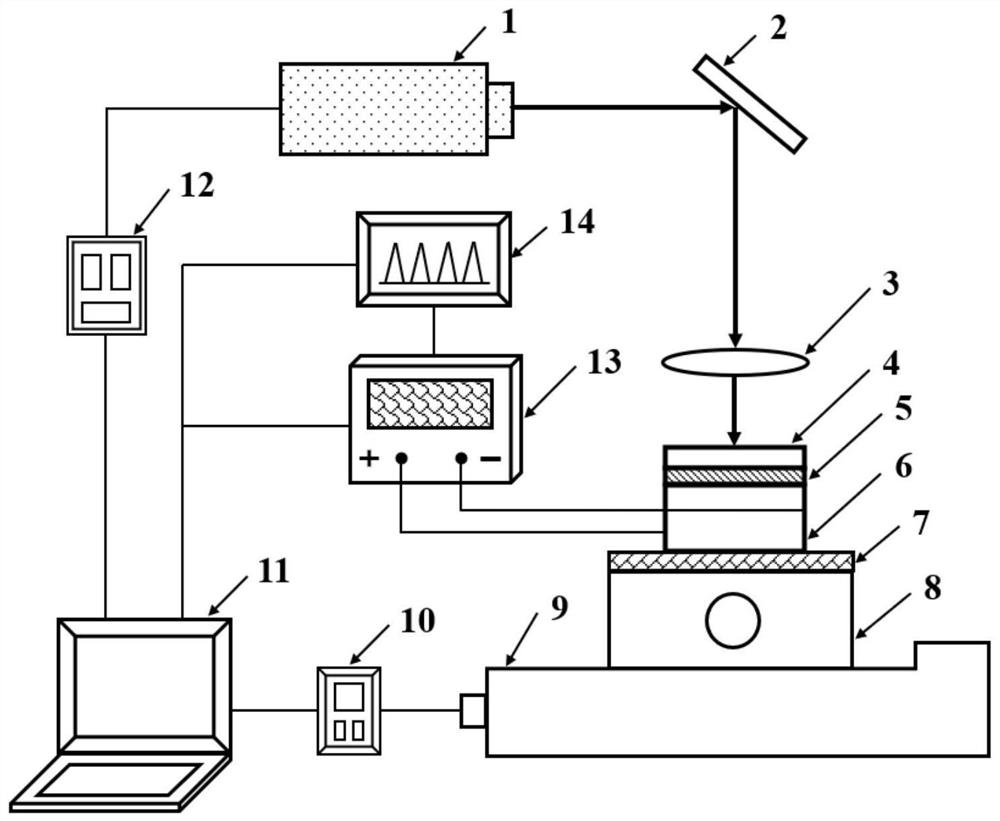

Image

Examples

Embodiment 1

[0024] A method for pulsed current coupling laser shot peening strengthening of metal materials, comprising the following steps:

[0025] (a) Grinding and polishing the surface of the metal material, and finally carrying out ultrasonic cleaning in industrial alcohol solution and drying for subsequent use;

[0026] (b) Under different process parameters, use the positive and negative electrodes to apply current to the surface of the pretreated sample for electric pulse treatment; take the maximum yield strength and elongation at break of the sample as the optimization target, and use the response surface optimization method to determine the The optimal electric pulse treatment process parameters; wherein, the electric pulse treatment process parameters are: pulse frequency 50-5000Hz, peak current 50-50000A, pulse width 20-2000μs, pulse time 10-600s;

[0027] (c) Under the optimal process parameters, the sample is subjected to electric pulse treatment, and the sample is tested w...

Embodiment 2

[0033] In this embodiment, the metal material is a TC4 titanium alloy plate, and the device and method of Embodiment 1 are used to process the material, and the coupling effect of the electroplastic deformation caused by pulse current and the ultra-high strain rate plastic deformation induced by laser shot peening is improved. The amplitude and depth of residual compressive stress can be adjusted to obtain more excellent comprehensive mechanical properties.

[0034] The method for the pulse current coupling laser shot peening strengthening metal material, may further comprise the steps:

[0035] (a) Grinding and polishing the surface of the TC4 titanium alloy plate, and finally carrying out ultrasonic cleaning in industrial alcohol solution and drying for subsequent use;

[0036] (b) Under different process parameters, use the positive and negative electrodes to apply current to the surface of the pretreated sample for electric pulse treatment; take the maximum yield strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser pulse width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com