Impeller high-inclination-angle laser oblique impact laser beam space energy distribution compensation method

A technology of spatial energy and distribution compensation, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as complex impeller structure, difficulty in laser shock strengthening treatment, and easy fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

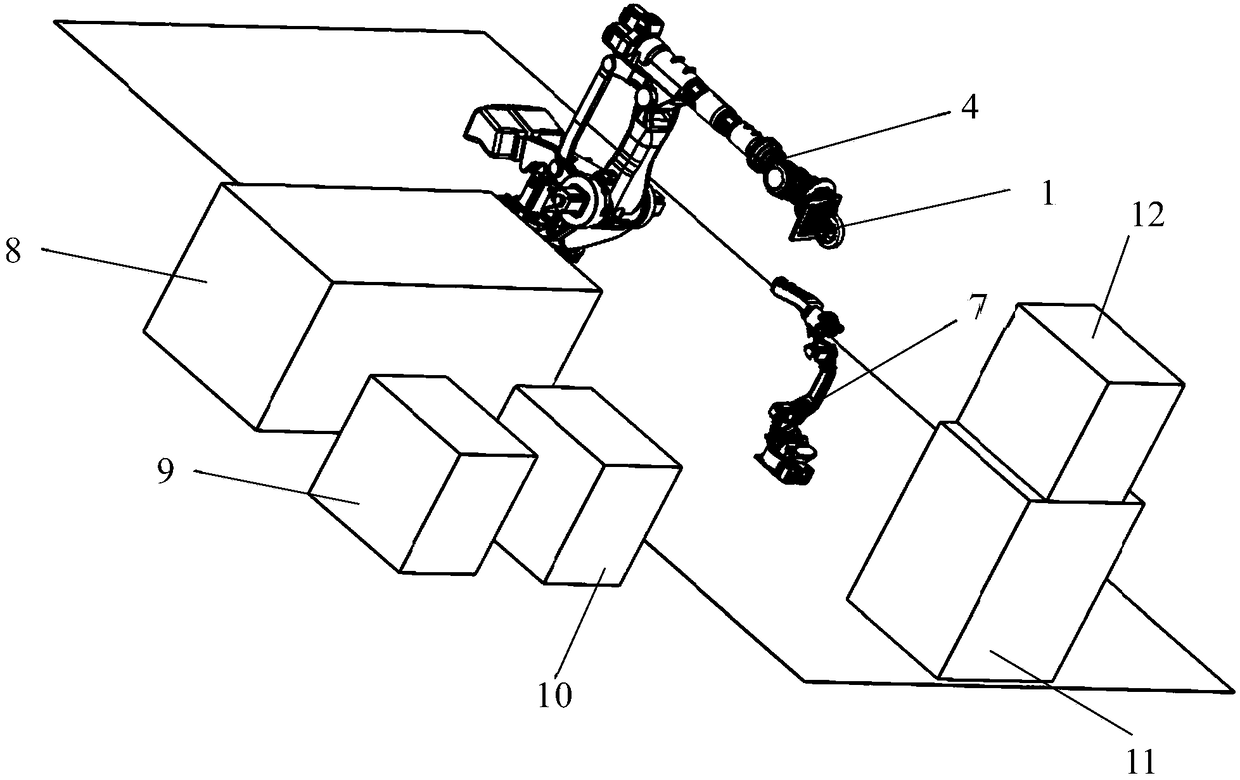

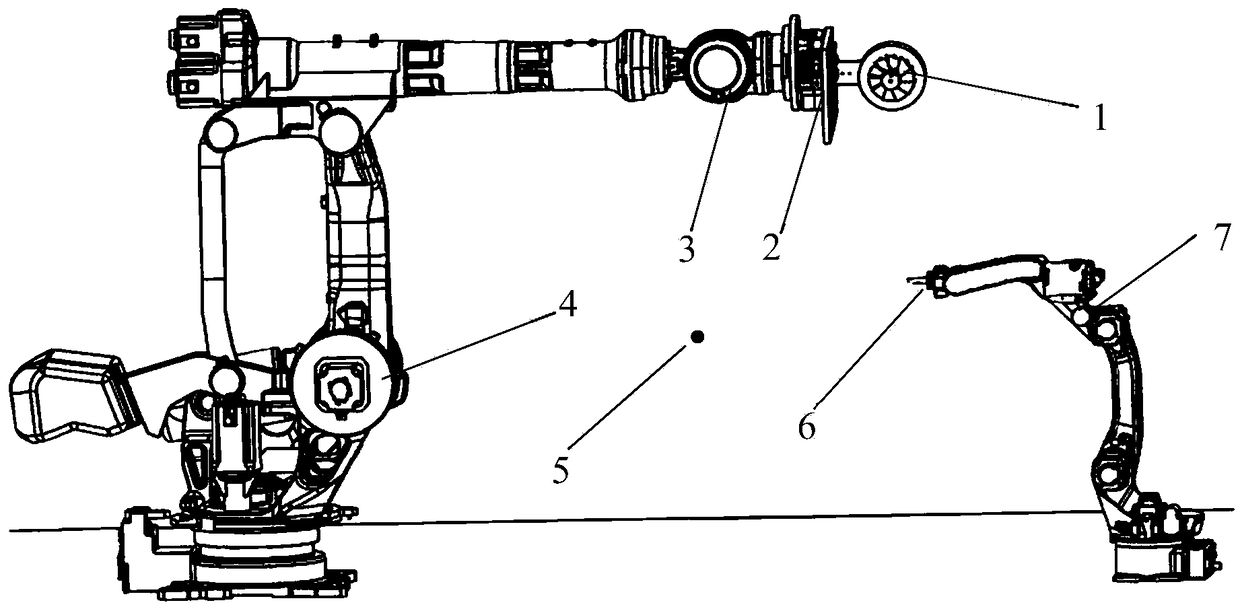

[0027] Whether the method in this embodiment is a simulation or an actual laser shock peening process, the following arrangement can be used to carry out. Such as figure 1 and figure 2 As shown, the impeller 1 (part) is mounted on a fixture 2 , which is assembled on a manipulator 3 , which may be part of a gripping robot 4 . The opposite side of the clamping robot 4 is a water-coating robot 7, and the mechanical arm of the water-coating robot 7 is provided with a water sprayer 6. The output of the laser generator 8 faces the impeller 1 . The laser power supply cabinet 9 and the laser control cabinet 10 are close to the laser generator 8 and supply power and control it; a laser peening system control system 12, which is used to control the laser peening system arranged at the output end of the laser generator; a robot control cabinet 11 It is used to control the action of clamping robot 4 and water coating robot 7. The impeller parts to be strengthened such as Figure 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com