Diffraction color changing laser marking method and apparatus thereof

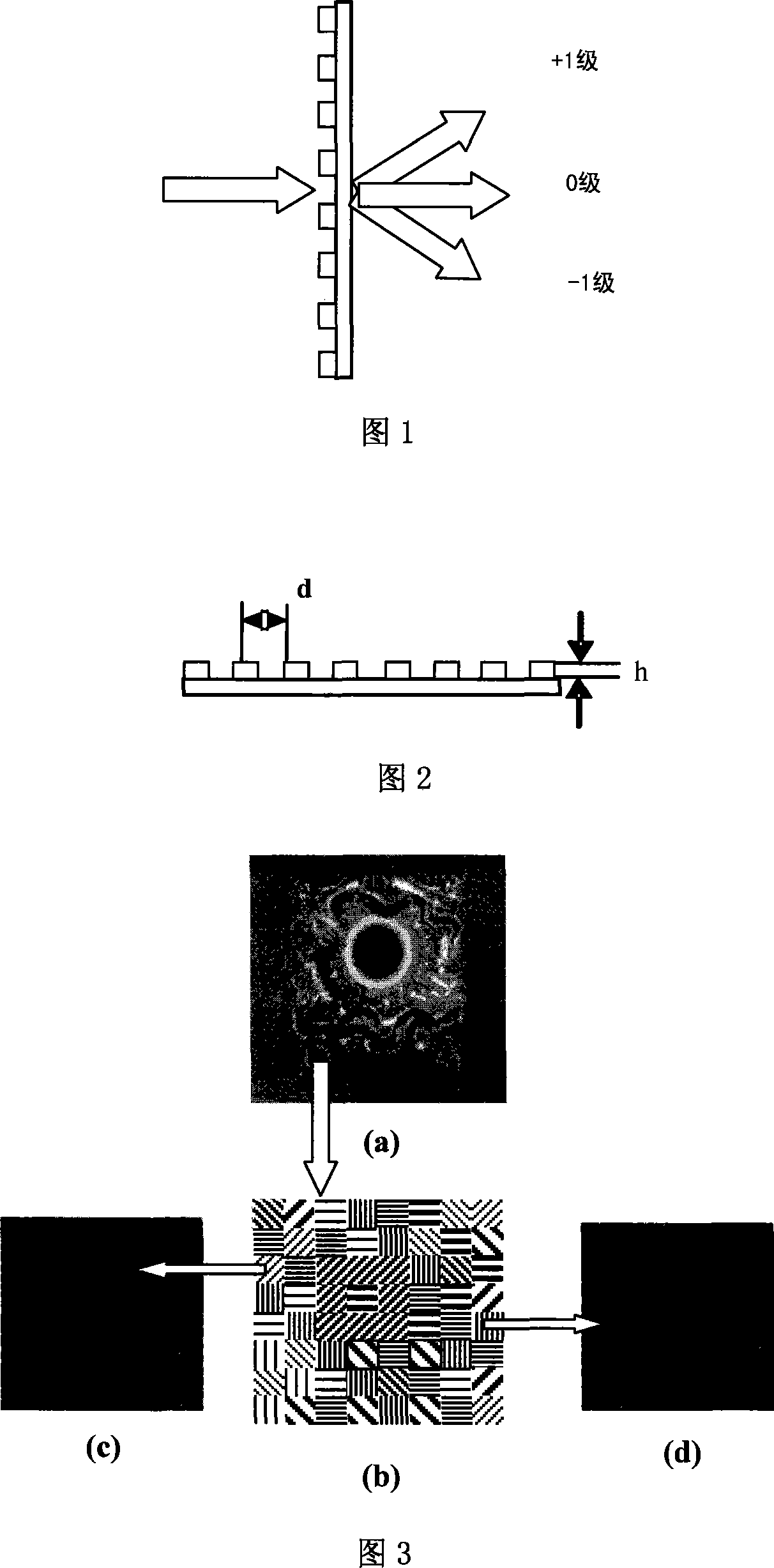

A laser marking method and laser marking technology are applied in the field of diffractive color-changing laser marking and devices, which can solve the problems of low image resolution, low absorption rate, difficulty in focusing, etc., so as to improve the resolution and reduce the etching depth. , The effect of uniform light intensity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

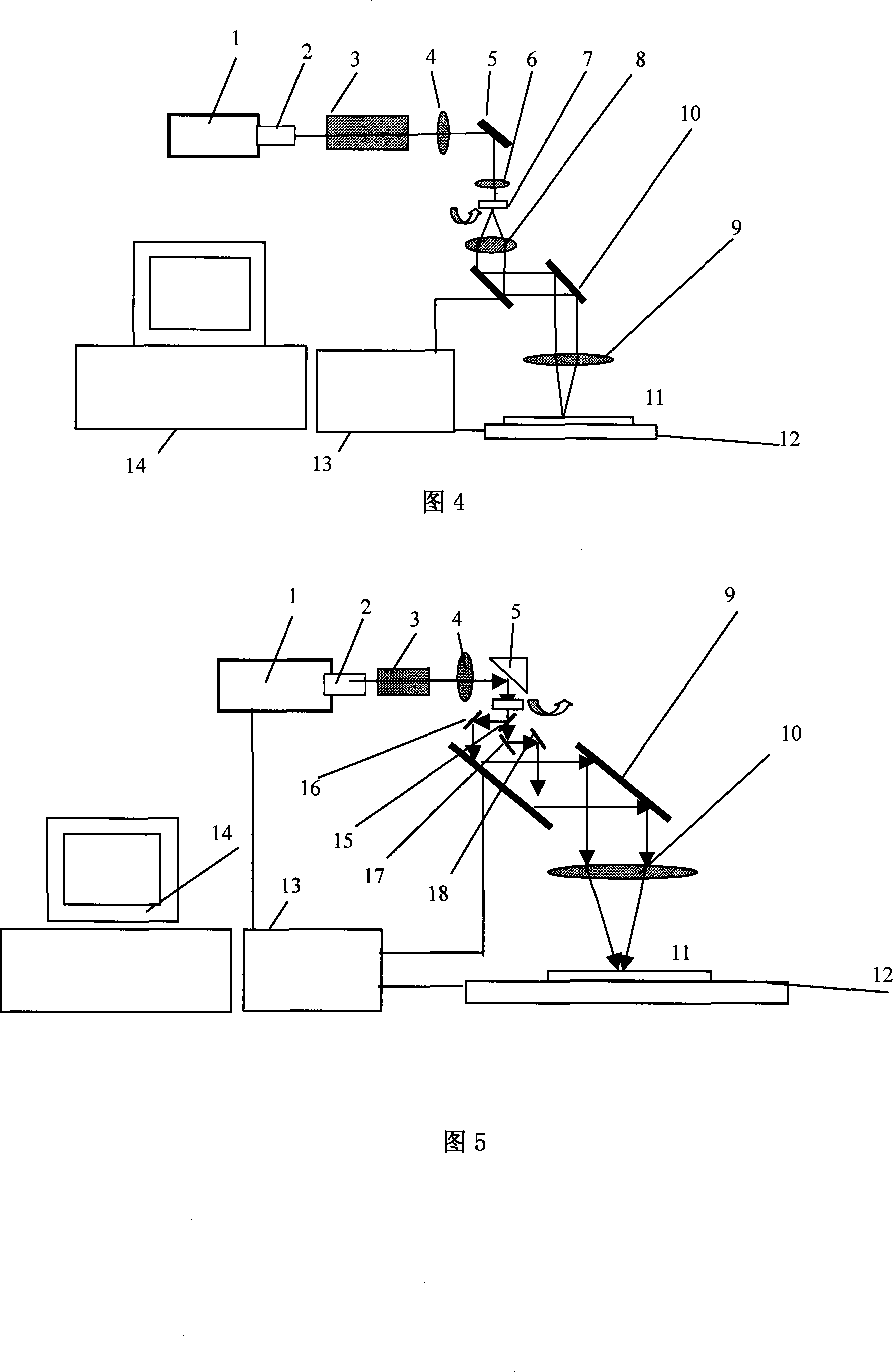

[0055] Embodiment 1: Refer to Figure 4, a method for making color-changing grating images. The image distribution is converted into pulse control signals. According to the orientation of the unit grating and the space frequency, the interference optical head, platform movement, grating rotation and light are simultaneously performed. Pulse input, etching on the surface of the material.

[0056] It consists of laser light source 1, beam expander 2, spot shaper 3, variable rectangular aperture imaging system 4, 5, 6 (lens 4, 6 and diaphragm constitute a 4F system with microfilm function), beam splitting system (including beam splitting Component quartz phase grating and turntable 7, imaging lens group 8, F-theta lens 9), the above-mentioned interference type optical head composed of light source, beam shaping, and beam splitting system, insert a 2-dimensional galvanometer between the imaging lens groups 8, 9 10. The material 11 is placed on the two-dimensional work platform 12 and t...

Embodiment 2

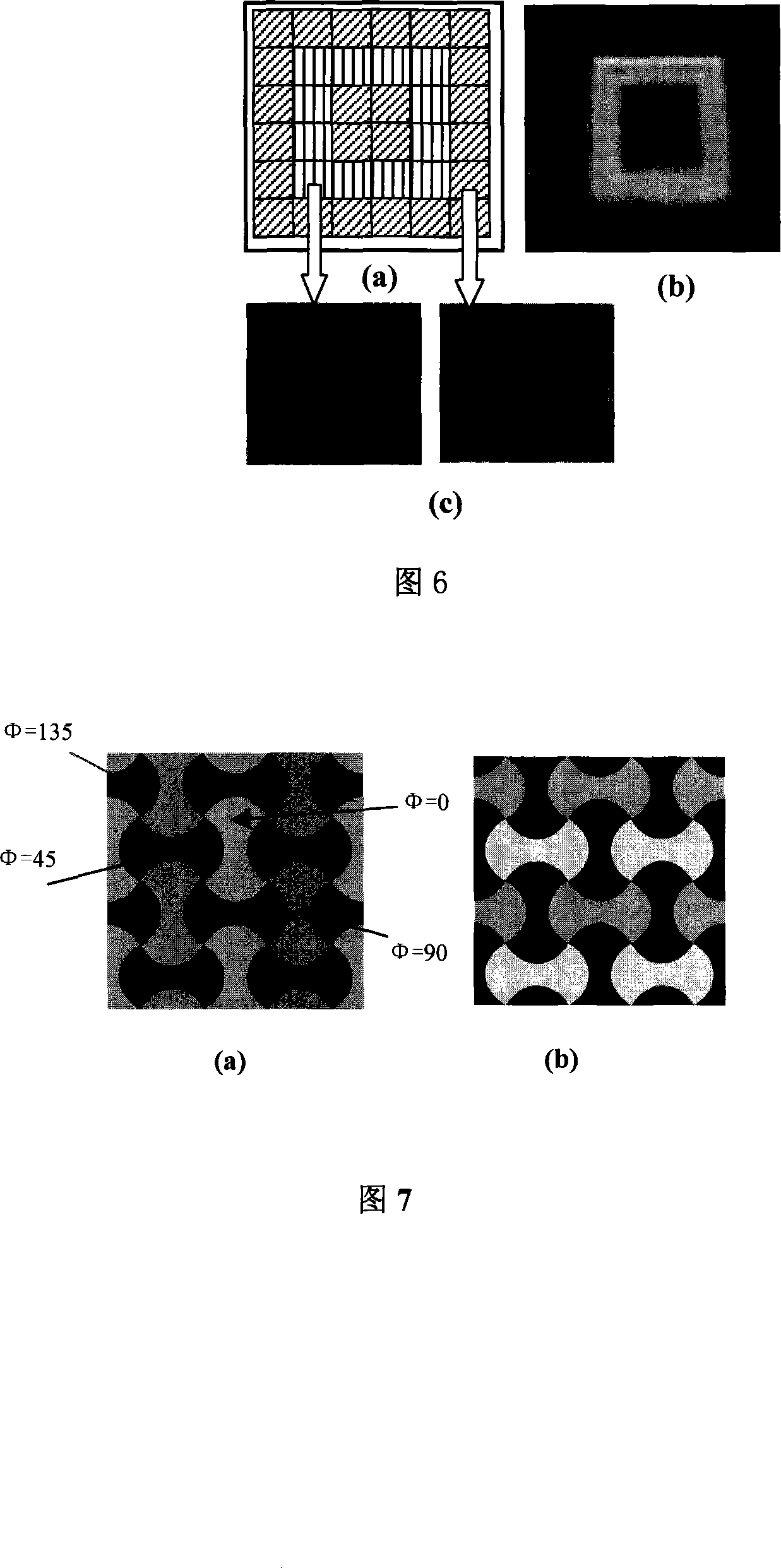

[0060] Embodiment 2: As shown in Figure 5, a laser etching and marking system is realized, including a DPSSL laser light source with a TTL signal interface 1, a beam expander collimator 2, an iris and a shaper 3, The quartz lens 4 (objective lens), the mirror 5 and the F-theta lens 9 together form a 4F system, which forms a reduced image on the surface of the recording material 11 for the rectangular diaphragm. Since the position of the beam splitting element has nothing to do with the shape of the final light spot, the beam splitting element should be as close as possible to the lens 4 to make the beam on the transflective beam splitter 14 larger. After the beam is split, it is reflected by the mirrors 15, 16, 17, and the parallel light after the split beam is condensed on the material 11 through the imaging lens group 10.

[0061] The above-mentioned interference optical head composed of laser light source, beam splitting element and imaging system, material 11 is placed on the ...

Embodiment 3

[0063] Embodiment 3: On the basis of Embodiment 1, the iris is opened to the minimum, the beam splitting element is rotated to a blank place, the laser beam does not split light, and directly penetrates the imaging lens group to adjust the light spot focused on the material To 2-50 microns, increase the repetition frequency of the pulsed laser beam, the marking system can directly write two-dimensional vector graphics, the system becomes a single-beam precision laser direct writing system, which can perform photoetching of precision circuit boards and reticles . The overall structure of the etching system of this embodiment is the same as that of the first embodiment, and the lens 9 adopts a shorter focal length (microscopic objective lens with high numerical aperture).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Etching depth | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com