Optimization process-based method for rapidly detecting bonding state of coating interface

A detection method and technology of optimization method, which can be applied to measuring devices, instruments, mechanical devices, etc., can solve the problems of long scratch paths, unusable workpieces, and complicated processing of test results, so as to improve scratch efficiency and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

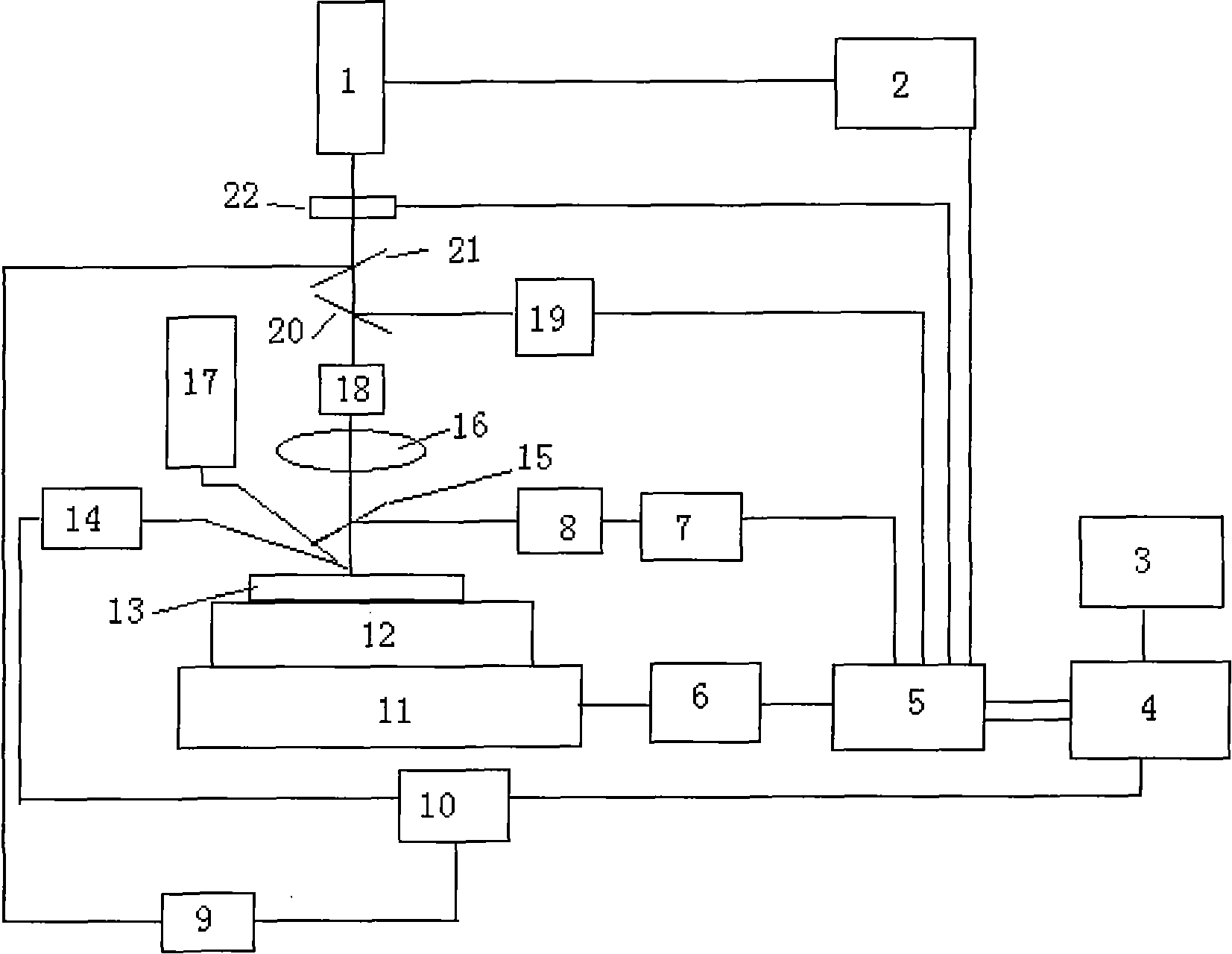

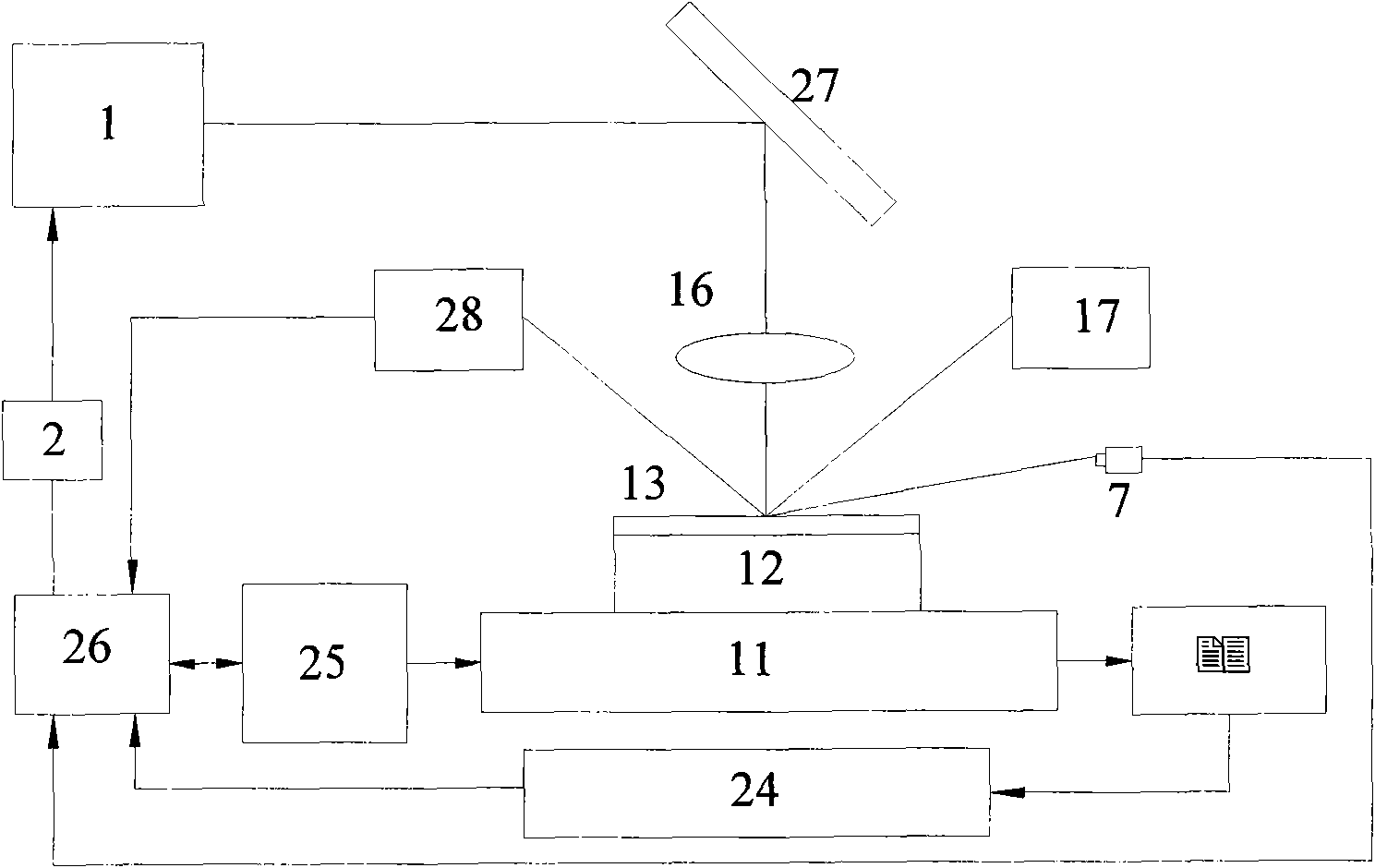

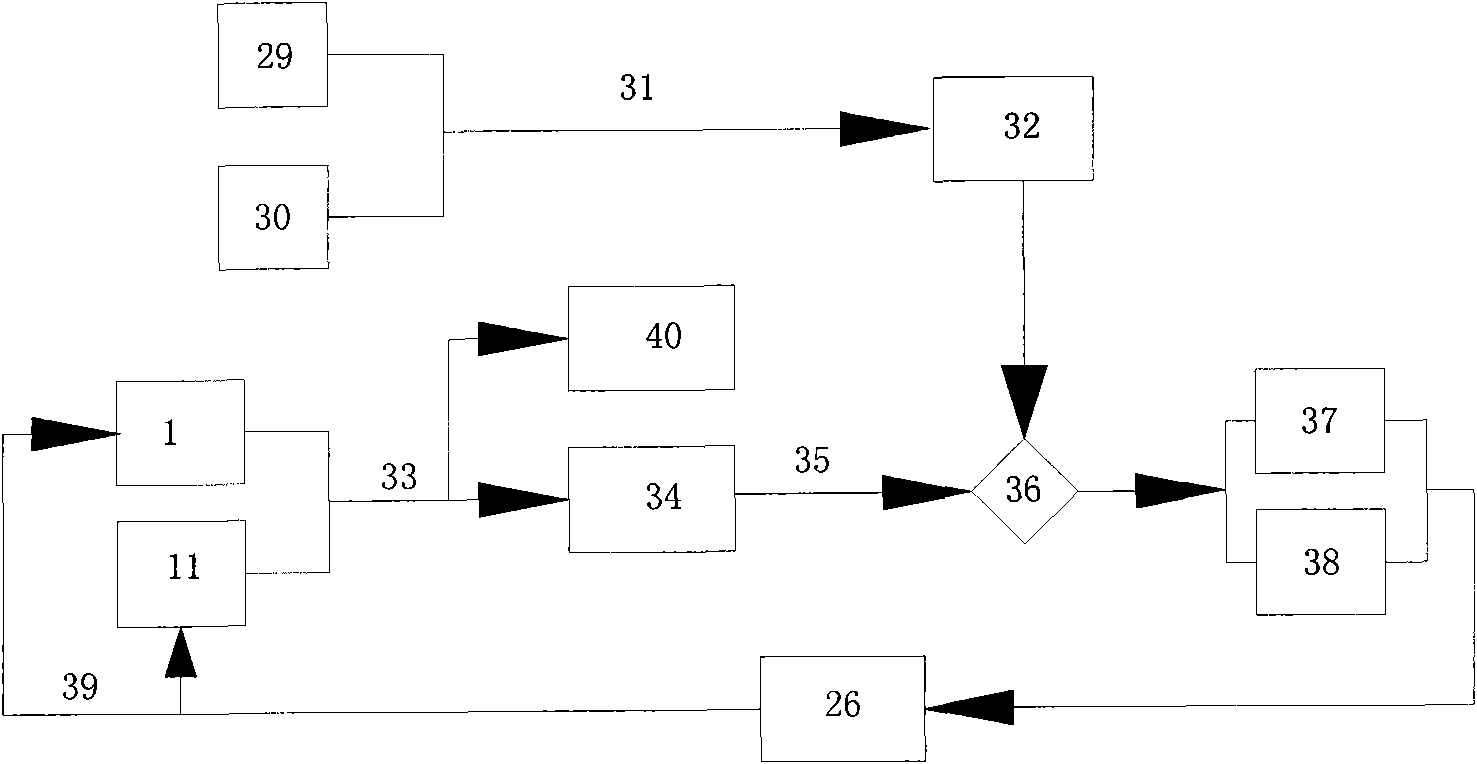

[0060] specific implementation plan

[0061] A martensitic stainless steel sample with a length of 80 mm, a width of 15 mm, and a thickness of 1 mm. The surface of the sample is prepared by a sulfamate nickel plating process with a stainless steel protective coating with a thickness of about 25 μm. Such as figure 2 , image 3As shown, the short-pulse laser beam directly acts on the surface coating of the sample 13 through the laser 1 . The sample 13 is fixed on the fixture 12 of the two-dimensional translation stage 11 ) to make discrete scratches 33 , the power of the laser is adjustable, and the laser and the workbench are uniformly controlled by the industrial computer 26 . The laser starting power is 150MJ-the laser ending power is 1000MJ, adjust the distance between the camera and the sample, and send the collected scratch images to the computer for real-time storage, which is used by the experiment operator for real-time monitoring for manual monitoring40. The core p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com