Automatic collection system of laser-induced breakdown spectroscopy

A laser-induced breakdown and automatic acquisition technology, applied in spectrum investigation, material excitation analysis, etc., can solve the problems of difficult to achieve precise laser positioning, waste of time, and cumbersome implementation of synchronous operation of sample movement and data acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

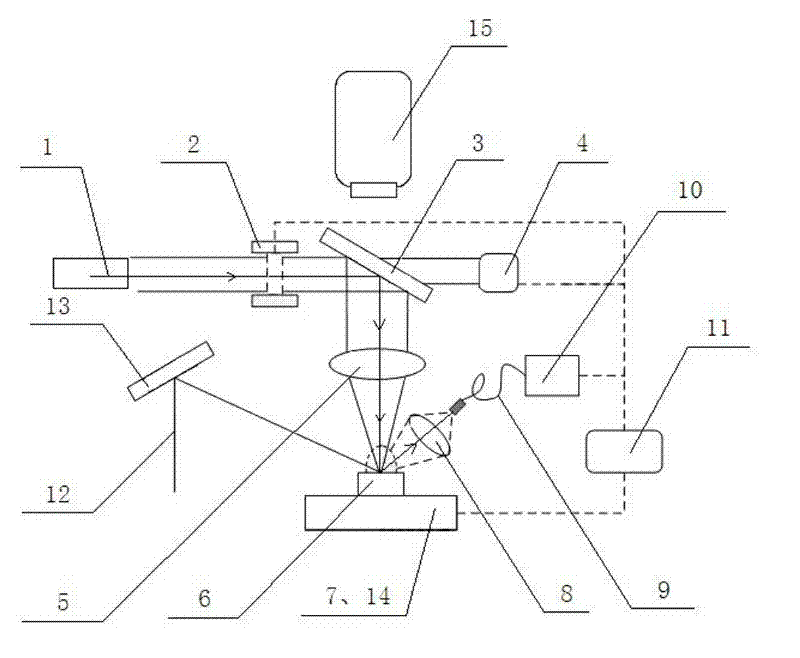

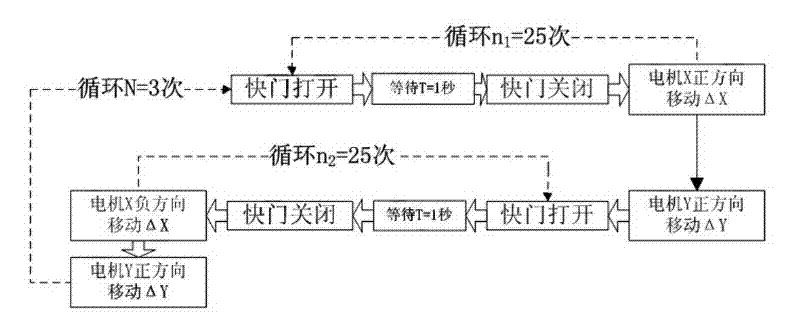

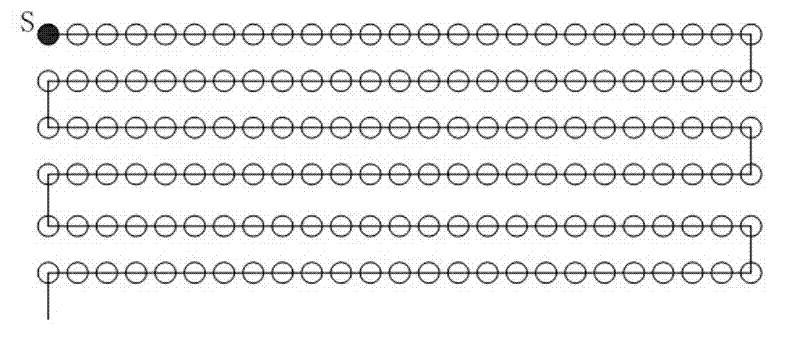

[0021] Example: such as figure 1 As shown, the horizontally emitted pulsed laser light 1 projects through the controllable shutter 2 in the open state to the mirror 3 placed at an angle of 45° to the pulsed laser light 1 . The pulsed laser 1 is emitted to the mirror 3, part of the pulsed laser is transmitted to the PIN tube 4, and after the trigger signal is generated by the PIN tube 4, the spectrometer 10 starts to collect data, and the other part of the pulsed laser is reflected by the mirror 3 to form a vertical pulse The laser light hits the focusing lens 5 whose optical axis is perpendicular to the platform 7 . The focusing lens 5 focuses the pulsed laser light 1 on the surface of the sample 6, and the sample 6 is placed on a platform 7 placed horizontally. The platform 7 is a movable platform, and the drive shaft of the platform 7 is connected with a stepper motor 14 . The pulsed laser light 1 goes from the surface of the sample 6 to the spectrometer 10 through the foc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com