Connector testing machine

A connector and testing machine technology, which is used in the testing of machine/structural components, instruments, measuring electricity, etc., can solve problems such as damage, small connector size, and two connectors eat one side, and achieve automatic alignment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

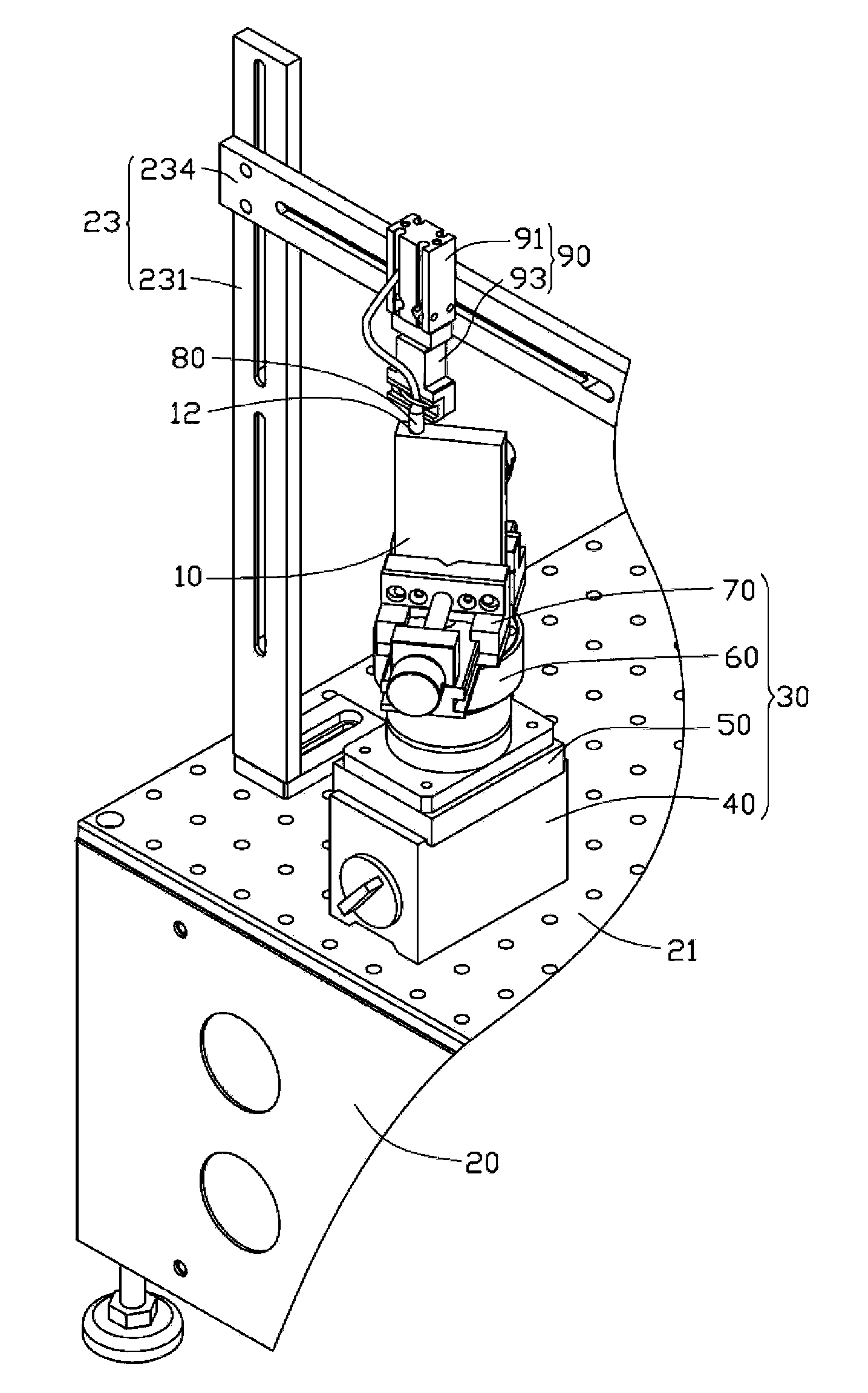

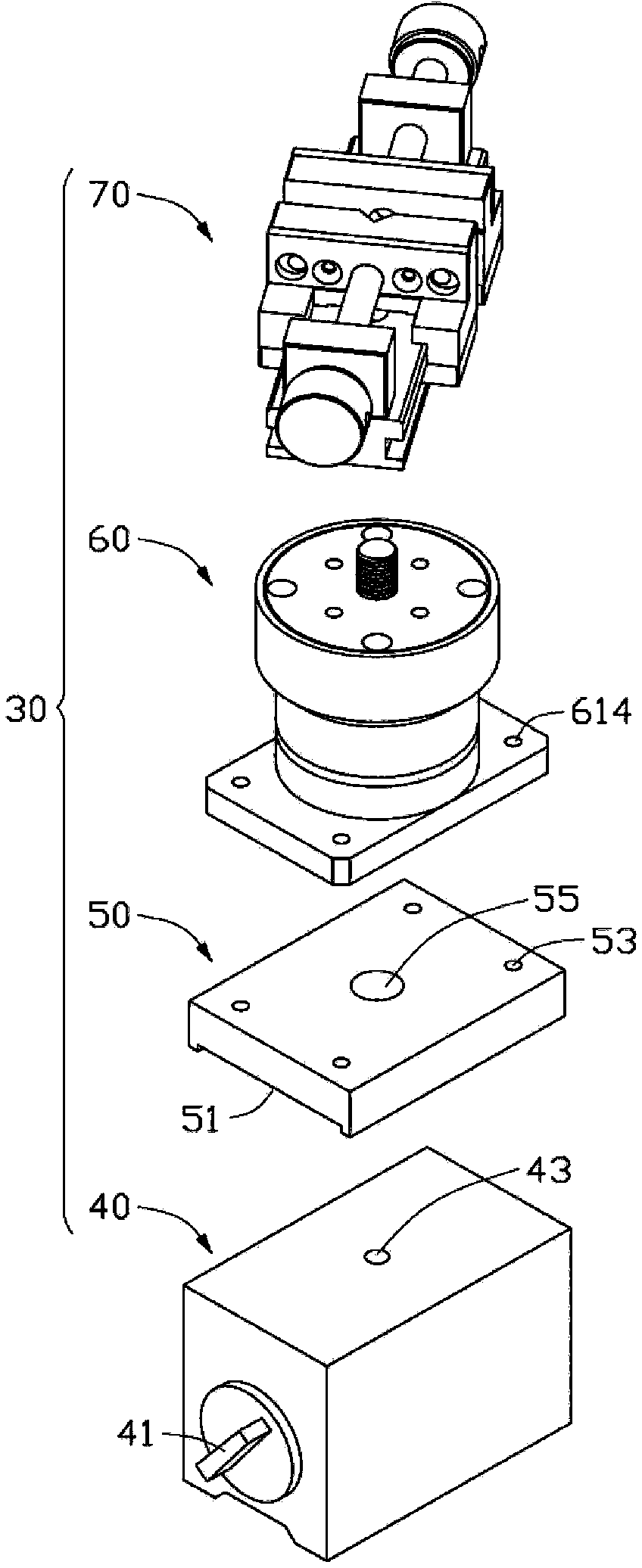

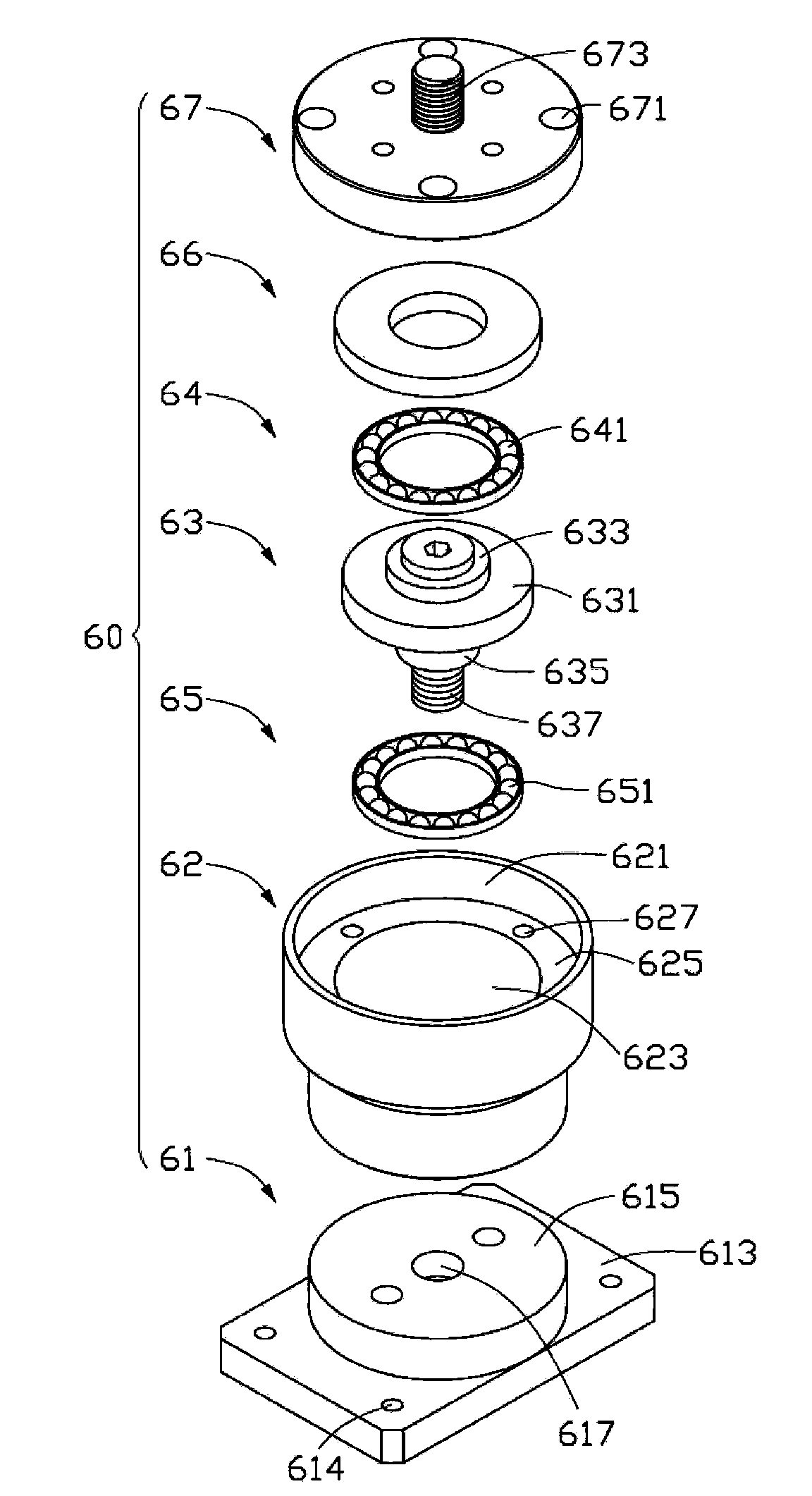

[0011] Please refer to figure 1 , is a preferred embodiment of the connector testing machine of the present invention, which is used to test the life of a connector 12 of an electronic product 10 . The connector testing machine includes a supporting platform 20 , a fixing component 30 and a plugging component 90 .

[0012] The support platform 20 includes a horizontal support plate 21 and a support frame 23 mounted on the support plate 21 . The support plate 21 is made of iron or other ferromagnetic materials. The support frame 23 includes two vertical support arms 231 (one support arm 231 is not shown in the figure) and a beam 234 connected to the two support arms 231 in a longitudinal position adjustable manner.

[0013] The plug assembly 90 is installed on the beam 234 of the supporting platform 20 in a horizontal position adjustable. The plug-in assembly 90 includes a cylinder 91 electrically connected to a control unit (not shown in the figure) and a connector fixing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com