Manufacturing method for laser-damage-resistant lithium niobate triple-band antireflection film

A technology of anti-reflection film and production method, which is applied in optics, sputtering coating, nonlinear optics, etc., can solve the problems of residual reflectivity, poor spectral characteristics, large scrap of residual reflection of products, etc., and achieve the negative effects of controlling random errors Influence, improve adhesion, ensure the effect of laser damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

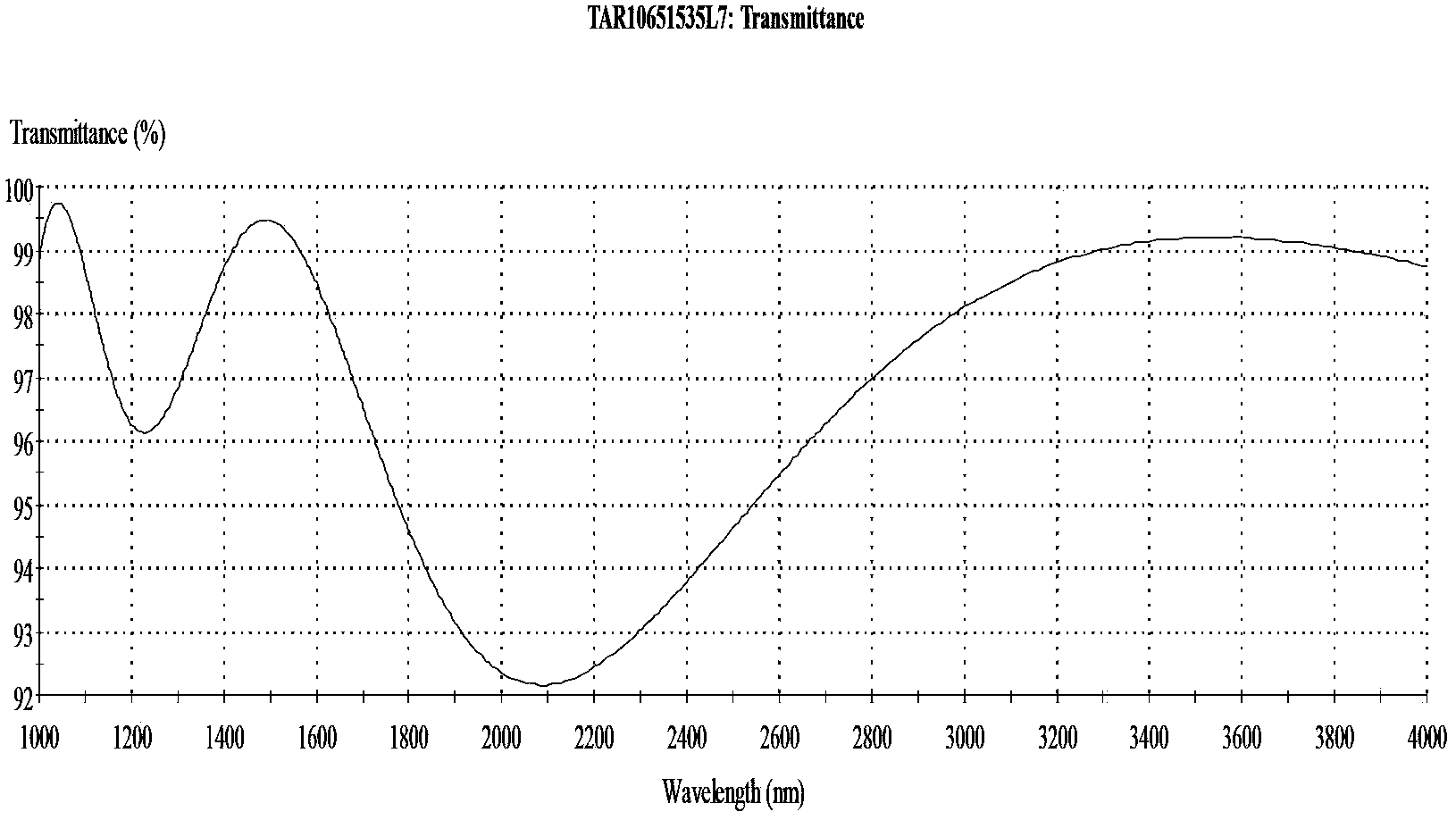

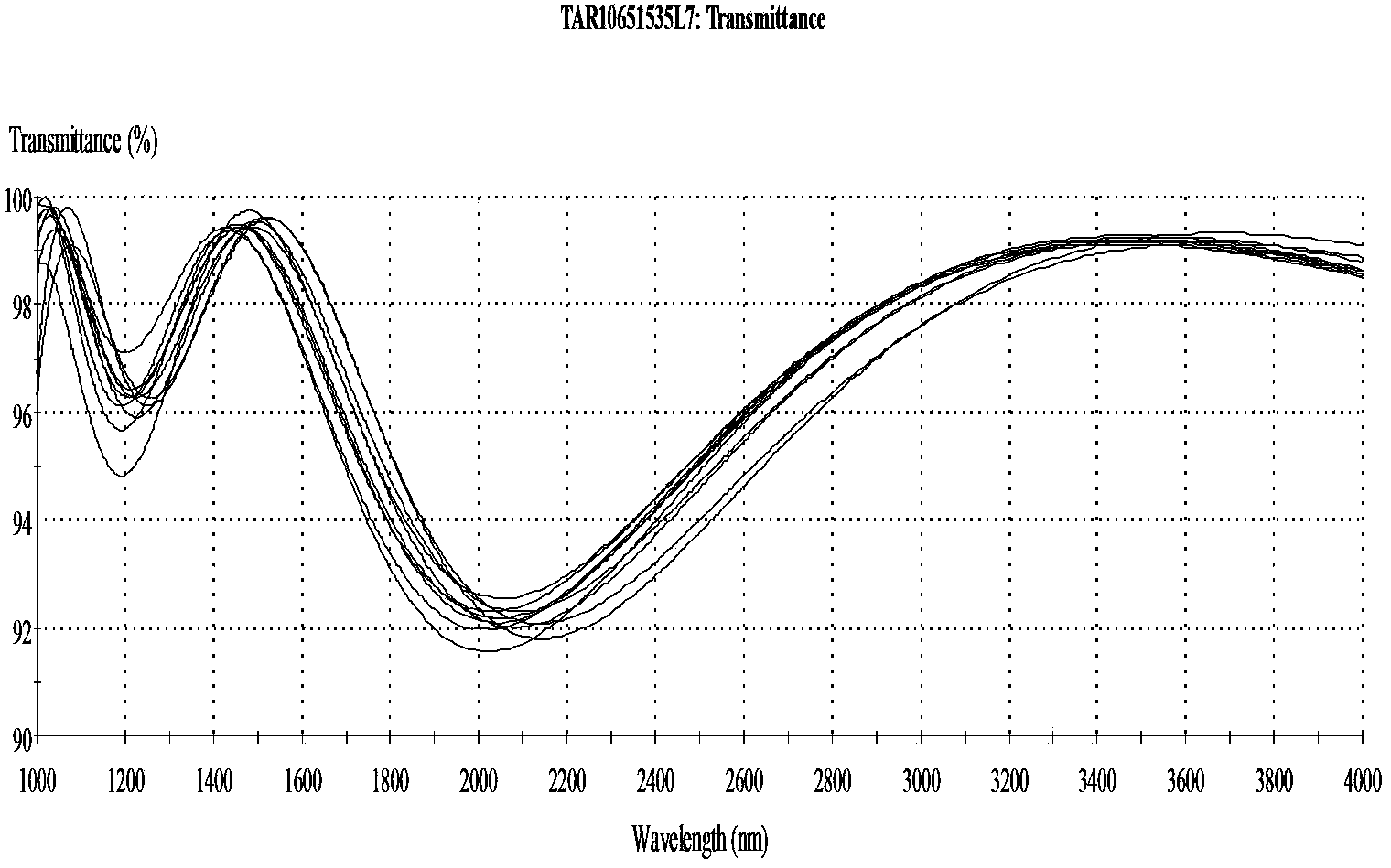

[0028] refer to figure 1 . According to the manufacturing method of the high damage threshold lithium niobate anti-reflection film of the present invention,

[0029] (1) Determine the theoretical film system, choose zinc sulfide ZnS as the high refractive index material, ytterbium fluoride YBF 3 It is a low refractive index material, aluminum oxide Al 2 o 3 are medium refractive index materials, define ZnS and Al respectively 2 o 3 and YBF 3 The unit optical thickness at λ / 4 is H, M and L, and the film thickness is determined according to the experimental film tensile test and laser damage test. On the computer, use the film system design software Essential Macleod to determine the initial structure of the film system according to the performance parameters required by the three-band anti-reflection; in the design of the film, the constraint conditions are lithium niobate and the first layer of YBF 3 There is a layer of Al in between 2 o 3 layer.

[0030] (2) Using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical damage threshold | aaaaa | aaaaa |

| optical damage threshold | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com