Big dial of circular knitting machine for double-faced fabric knitting

A double-sided fabric, circular knitting machine technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of complex research and time-consuming adjustment, save the adjustment time, improve the overall processing accuracy, solve the The effect of the assembly positioning problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

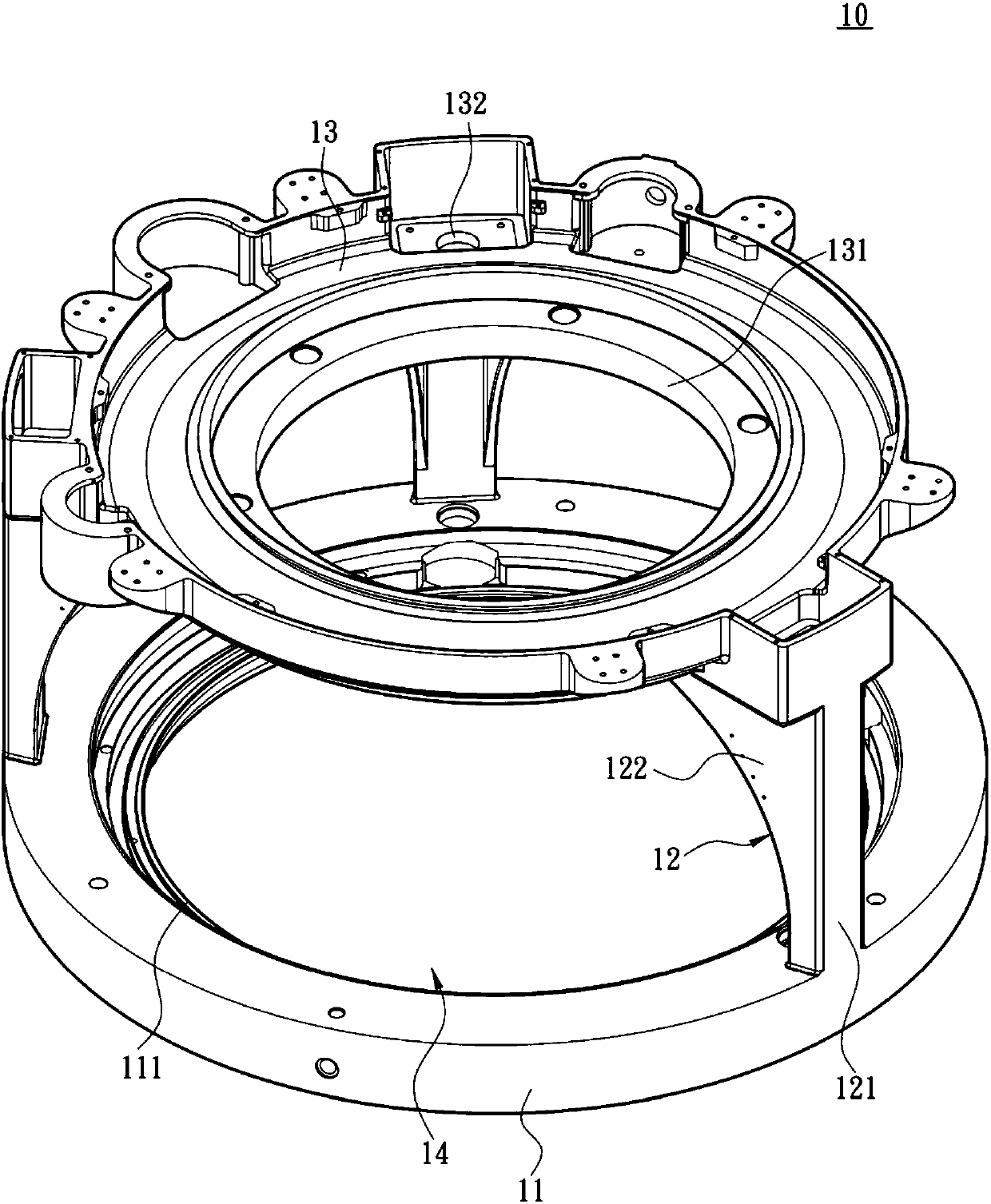

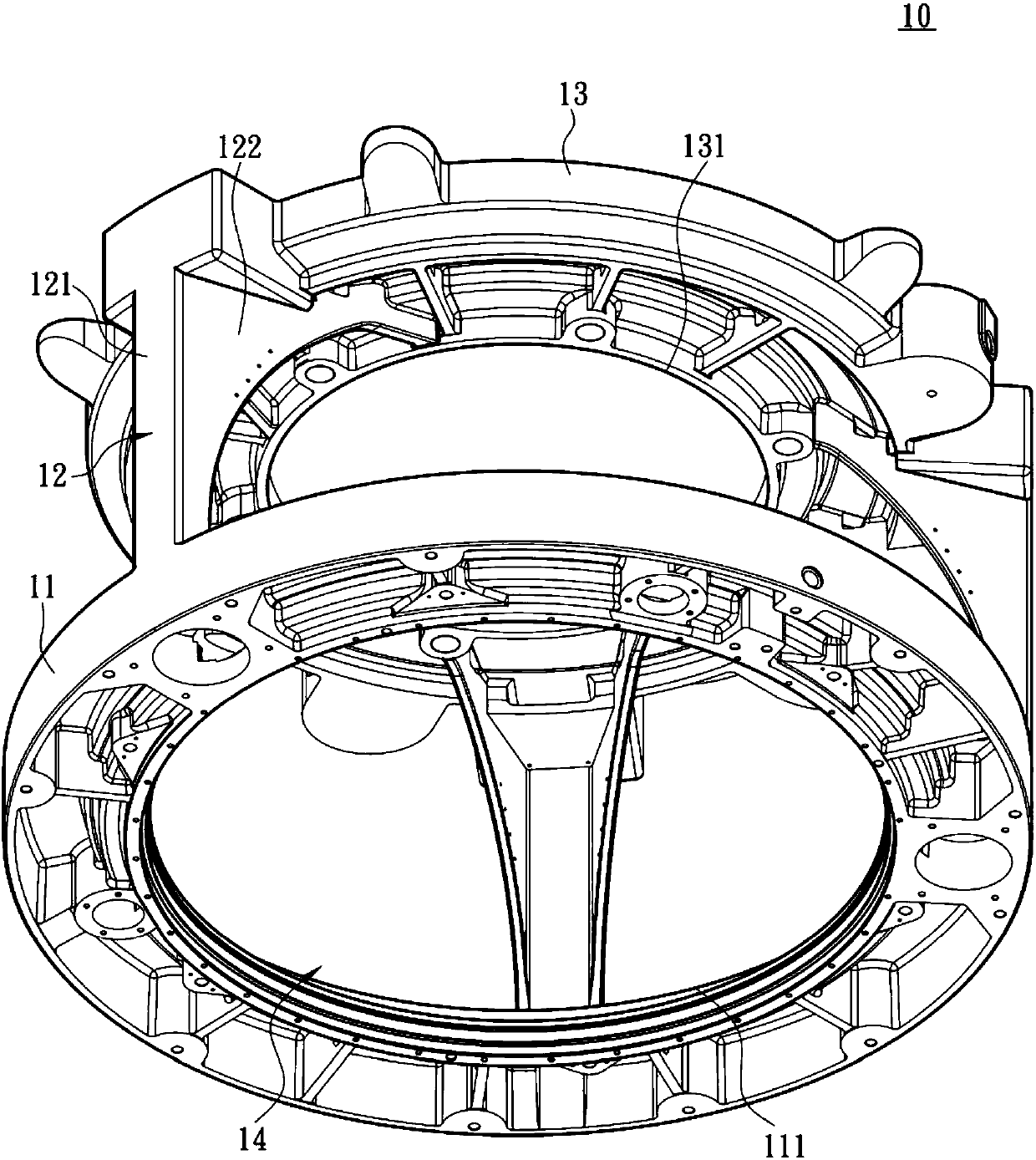

[0030] Detailed description and technical content of the present invention, now just explain as follows with respect to matching drawing:

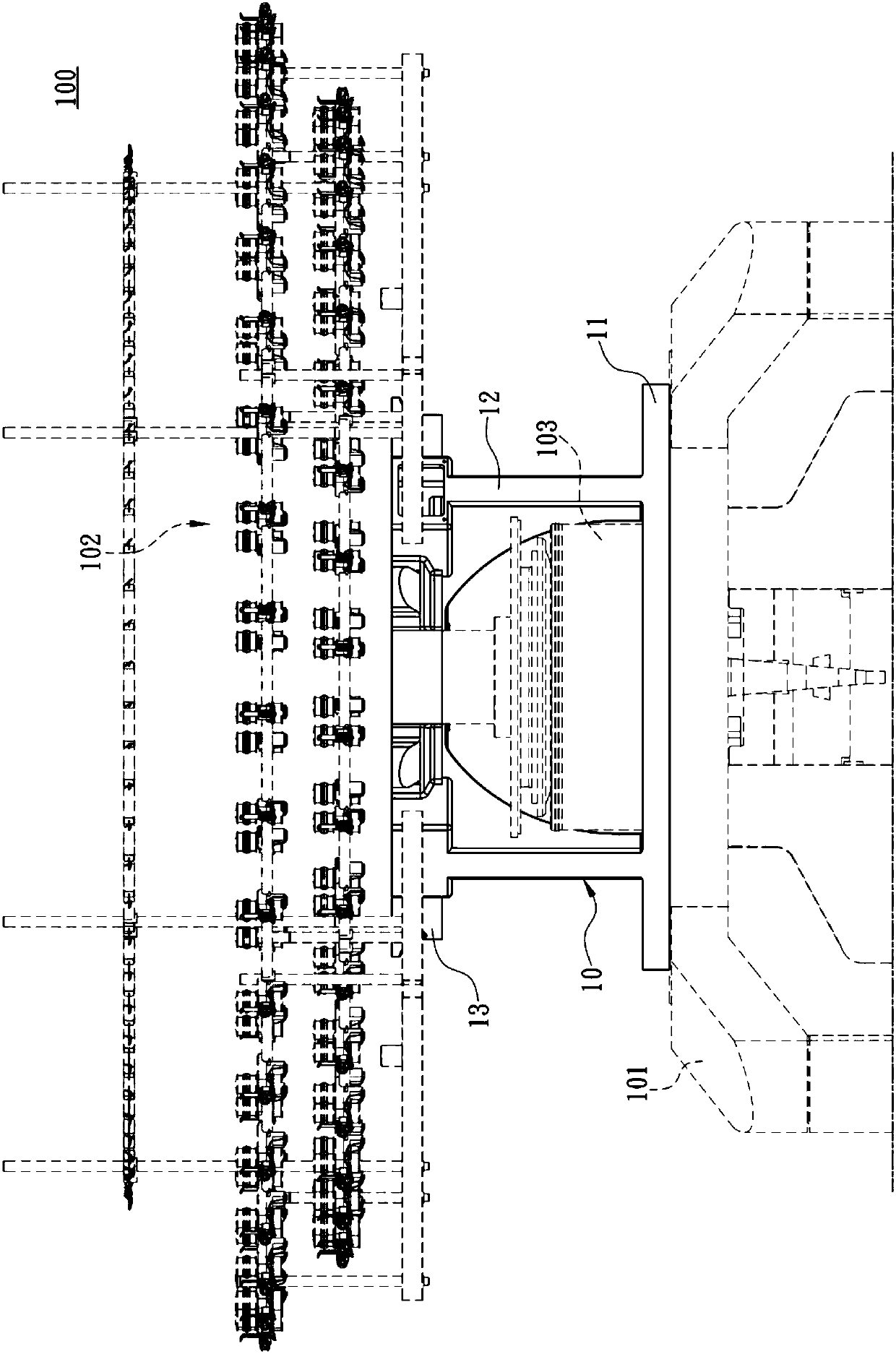

[0031] see Figure 1 to Figure 4 , the present invention provides a circular knitting machine pan 10 for weaving double-sided fabrics, the circular knitting machine pan 10 includes a large pan base 11, three feeding ring support parts 12, a yarn feeding ring part 13 and an installation space 14 , and the large plate base 11, the three yarn feeding ring support parts 12 and the yarn feeding ring part 13 are integrally manufactured based on mechanical processing, and the so-called mechanical processing can be casting.

[0032] Further, the large plate base 11 is disc-shaped, and has a first opening 111 formed in a hollow. In addition, the three yarn feeding ring support parts 12 respectively extend in the same direction and are perpendicular to the large disk base 11, and the three yarn feeding ring support parts 12 are arranged at interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com