A straightening machine

A straightening machine and straightening technology, applied in the field of straightening machines, can solve the problems of wasting time and spending a lot of time when replacing bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

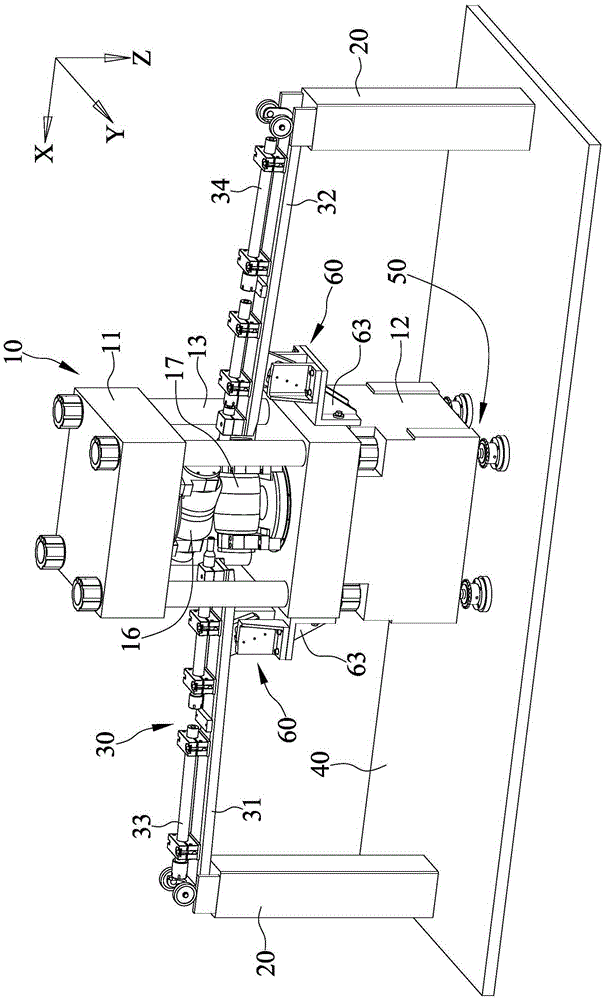

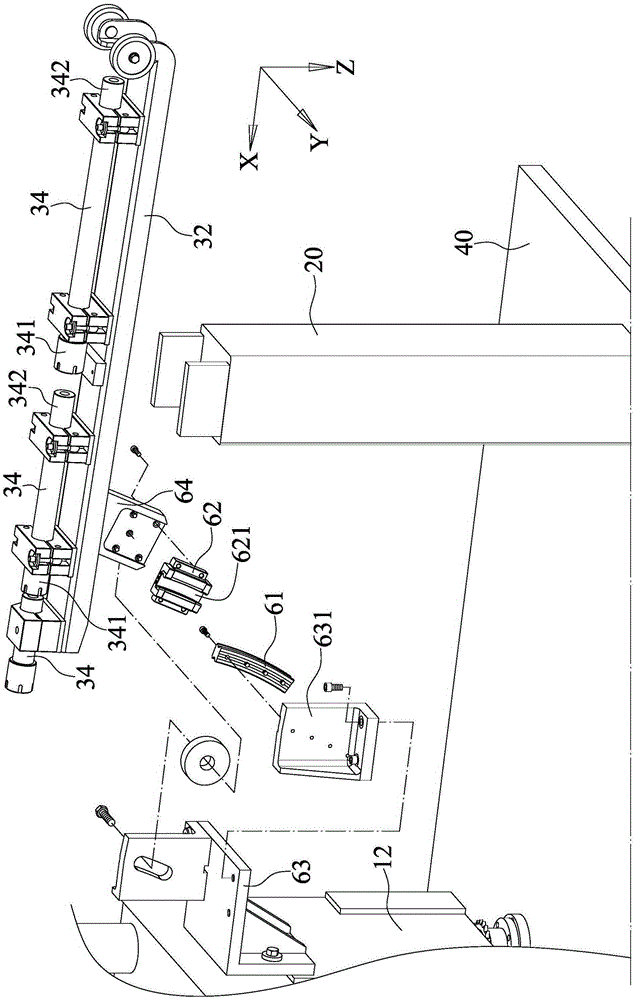

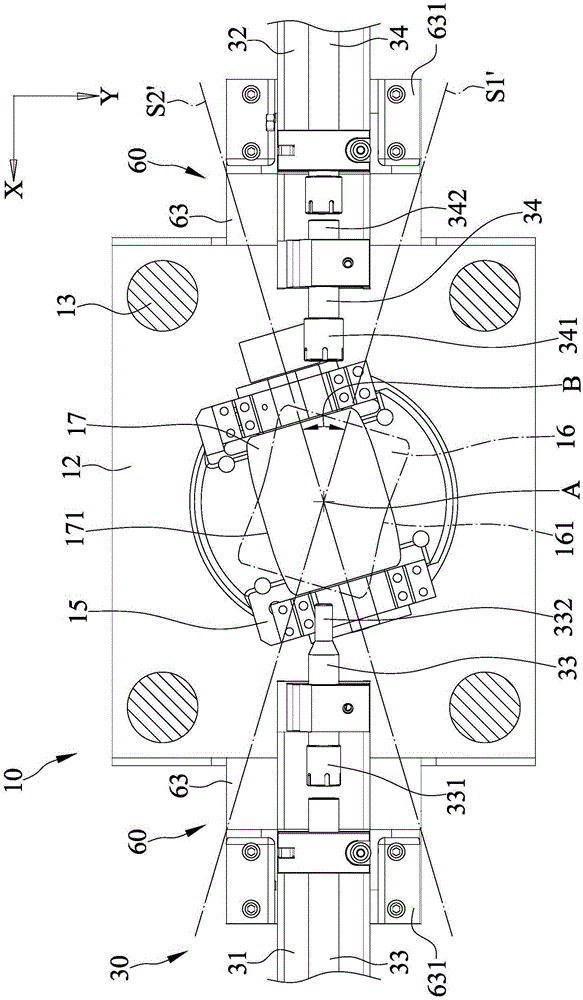

[0032] refer to Figure 1 to Figure 6 . A straightening machine of the present invention includes a straightening device 10, two supporting bodies 20, a track group 30, a base 40, a lifting group 50 and two sliding devices 60, the straightening device 10 is connected to the lifting group 50, the two supporting bodies 20 and the end of the lifting group 50 away from the straightening device 10 are set on the same surface of the base 40, the straightening device 10 is located between the two supporting bodies 20, and the track group 30 is slid At one end of the two supporting bodies 20 away from the base 40, one of the two sliding devices 60 is connected between the straightening device 10 and the track set 30, and the other sliding device 60 is connected to the straightening device 60. Between the device 10 and the track set 30 , the track set 30 can pivot relative to the straightening device 10 and slide relative to the two supporting bodies 20 . In this embodiment, the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com