A system and method for unmanned mining of coal mines

A coal mine, system monitoring technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

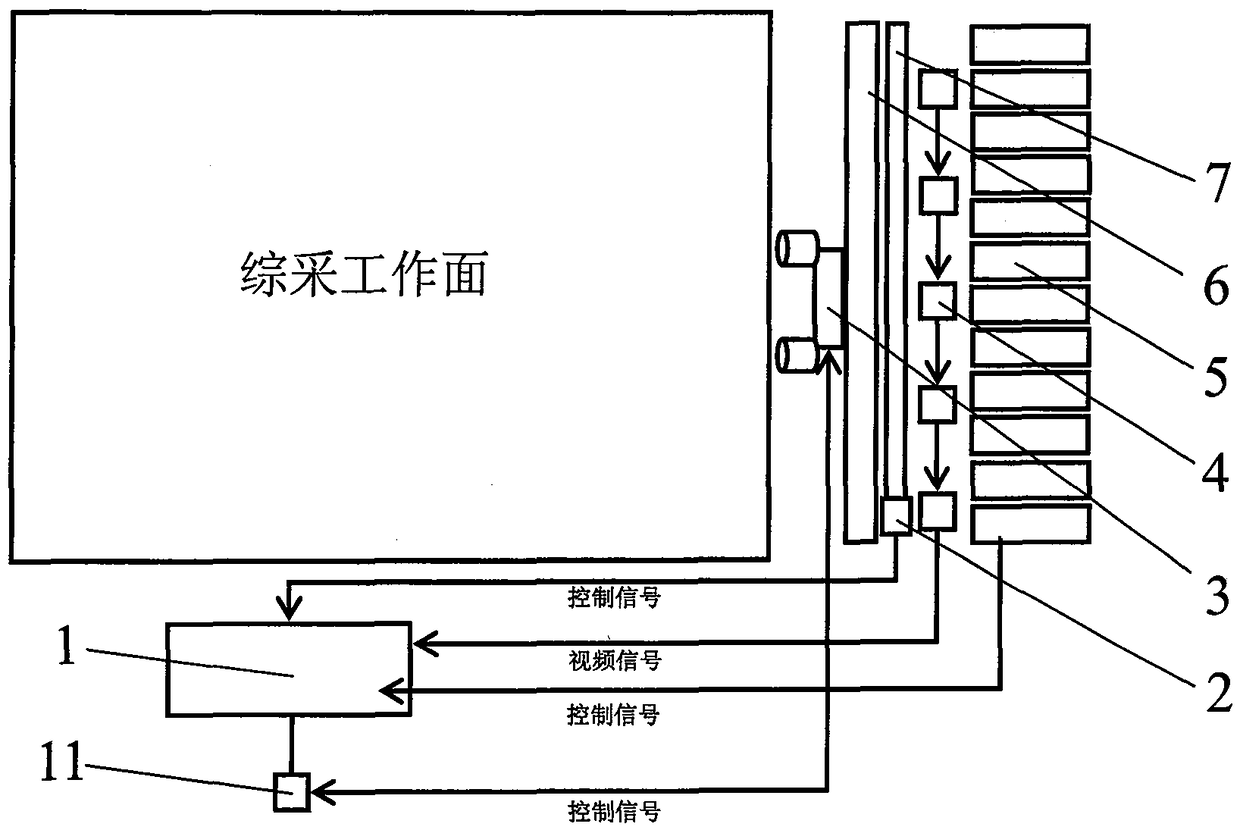

[0018] See attached figure 1 , which shows a preferred embodiment of the coal mine unmanned mining system according to the present invention.

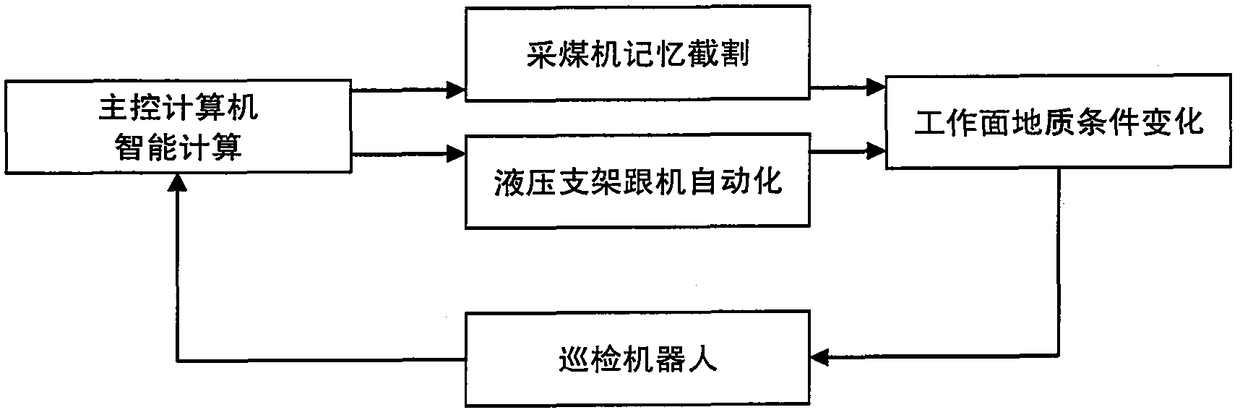

[0019] An unmanned coal mine mining system, used for fully mechanized mining face mining, consists of a drum shearer, a main control computer, an inspection robot, a hydraulic support electro-hydraulic control system, a remote operation console, a coal wall video camera, etc. device configuration. The main control computer is electrically connected to the inspection robot and the coal wall video camera, and is used to receive the monitoring information collected by it. The operation mode of the inspection robot on the working face can be to run on the track, as described in this embodiment, it can also be It is walking on the working surface, or even flying. If the track is used, it can generally be located on the scraper conveyor or hung under the top beam of the hydraulic support, and traverse the entire working surface; the main co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com