Thin coal seam unmanned automated mining mode

A thin coal seam and pattern technology, applied in mining equipment, earthwork drilling, cutting machinery, etc., can solve the problems of narrow working space, poor safety, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The instruments and equipment in the specific embodiment of the present invention are equipment well known to those skilled in the field of coal mining technology, and can be obtained by purchasing.

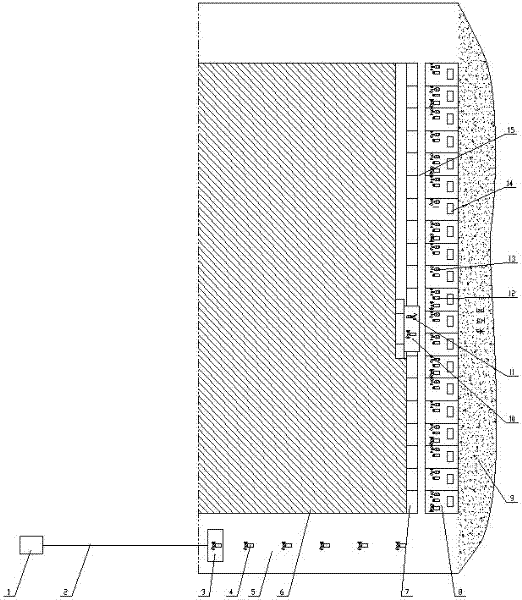

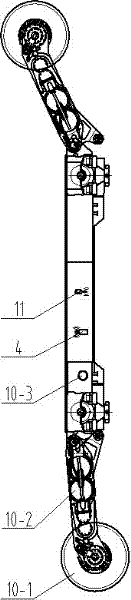

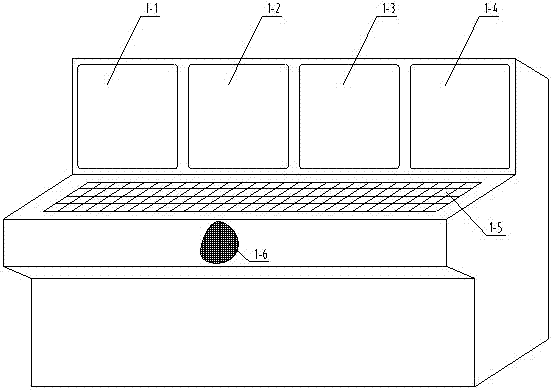

[0013] Such as figure 1 As shown, the unmanned working face in the thin coal seam adopts the longwall and retreating method for mining. The main coal mining equipment in the working face 15 is composed of a scraper conveyor 7, a hydraulic support 8 and a shearer 10; the hydraulic support 8 faces the The direction of the shearer 10 is the coal seam 6, and the direction of the hydraulic support 8 facing away from the shearer 10 is the goaf 9; the shearer 10 moves back and forth on the scraper conveyor 7 for coal cutting and coal loading, and the hydraulic support 8 pushes The scraper conveyor 7 moves forward, pulls the frame, pushes and slides, and pushes the working face forward for mining; the control center 1 and the trough controller 3 form a wired network through the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com